- Machining centres

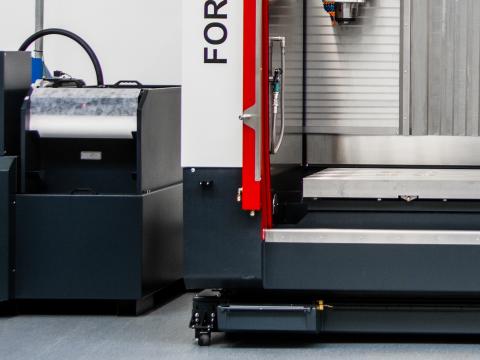

- FORTE rangeVertical machining centers

- ACURA range5-axis machining centres with rotary/tilt table unit

- TILTENTA rangePivotable spindle 4/5-axis-machining

- TILTENTA 7-2600

- TILTENTA 7-2000 NEO

- TILTENTA 7-2600 NEO

- TILTENTA 7-3600 NEO

- TILTENTA 9-2600

- TILTENTA 9-3600

- TILTENTA 9-4600

- TILTENTA 9-4600 2R

- TILTENTA 10-2600

- TILTENTA 10-3600

- TILTENTA 10-4600

- TILTENTA 10-4600 2R

- TILTENTA 10-6200

- TILTENTA 10-6200 2R

- TILTENTA 11-2600

- TILTENTA 11-3600

- TILTENTA 11-4600

- TILTENTA 11-4600 2R

- Machining centres availableMachining centres direct from the manufacturer. Very short delivery times!

- Automation

- Automation + ACURAMachining centres with a swivel rotary table

- Pallet automationMARATHON, INDUMATIK, EROWA

- Workpiece automationBMO, ROBOJOB, LANG

- Linear chain linkingLinear chain linking with ACURA 5-axis machining centres

- Tool automationStandby magazine

- Automation + TILTENTAMachining centres with pivoting spindle and NC rotary table

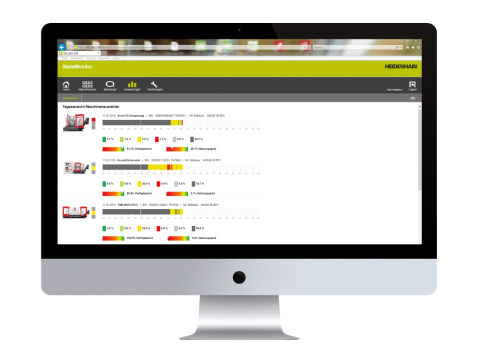

- Automation interfacesInterface solutions for automation

- Automation + ACURAMachining centres with a swivel rotary table

- Technology

- Areas of application

- Mechanical engineering

- Tool and mould making

- Contract manufacturing

- Food and packaging technology

- Agricultural engineering

- Plastics engineering

- Aecronautical and aerospace engineering

- Automotive industry

- Process technology

- Power engineering

- Medical engineering

- Shipbuilding and ship engineering

- Rail vehicles and rail technology

- Research and education

- Customer service

- Company