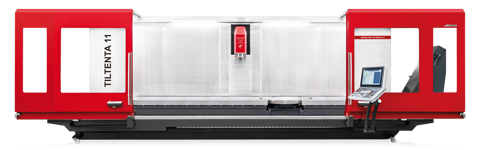

The high-performance machining centres in the TILTENTA range perform all sorts of machining tasks in the areas of mechanical engineering, tool and mould construction, shaft and roll machining, and the aerospace industry. The large work area with infinitely variable, pivotable main spindle allows for the vertical machining of long workpieces weighing up to 6,000 kg. Moreover, the integrated NC rotary table and a workspace partition also offer precise 5-side machining of parts weighing up to 1,800 kg in pendulum mode. The machining centres are notable for their vertical stainless steel covers, allowing optimal chip removal and the full encapsulation of the working area as standard.