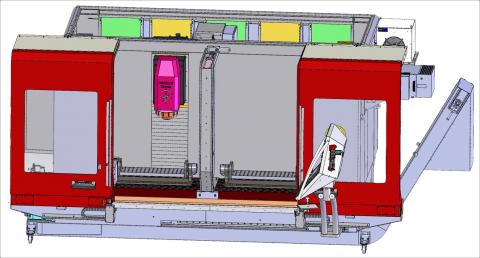

Image: NC rotary table with face plate, pivoting bridge with grid-patterned borings and counterholders

For quick retooling, the pivoting bridges are mounted on a baseplate so that they can be inserted into or removed from the machining centre quickly if required. The pivoting bridge itself can be provided with grid-patterned borings or zero-point clamping systems to ensure rapid clamp changing. HEDELIUS offers both standardised pivoting bridges and custom solutions. As a way of reducing machining centre downtime even further, HEDELIUS longbed moving column machining centres can also be used with two pivoting bridges in pendulum mode. Inserting a working space partition creates two machining spaces in which pieces can be clamped in and released in alternation.

While the pivoting bridge is being loaded with new raw parts in one workspace, they are being machined in the other. Changing the workspace only takes a few seconds. We would be happy to advise you and present you with our solutions and options.