- Bearbeitungszentren

- FORTE BaureiheVertikale Bearbeitungszentren

- ACURA Baureihe5-Achs-Bearbeitungszentren mit Dreh-Schwenktischeinheit

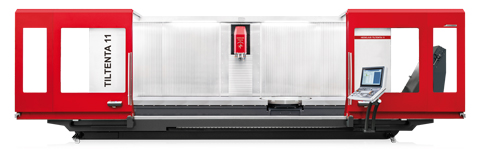

- TILTENTA Baureihe4/5-Achs-Bearbeitungszentren mit schwenkbarer Hauptspindel

- TILTENTA 7-2600

- TILTENTA 7-2000 NEO

- TILTENTA 7-2600 NEO

- TILTENTA 7-3600 NEO

- TILTENTA 9-2600

- TILTENTA 9-3600

- TILTENTA 9-4600

- TILTENTA 9-4600 2R

- TILTENTA 10-2600

- TILTENTA 10-3600

- TILTENTA 10-4600

- TILTENTA 10-4600 2R

- TILTENTA 10-6200

- TILTENTA 10-6200 2R

- TILTENTA 11-2600

- TILTENTA 11-3600

- TILTENTA 11-4600

- TILTENTA 11-4600 2R

- Kurzfristig lieferbarBearbeitungszentren direkt vom Hersteller. Sehr kurze Lieferzeit!

- Messe- und VorführmaschinenGut gepflegte Maschinen, Top-Qualität made in Germany, sofort verfügbar!

- Automation

- Automation + ACURA/FORTE3- und 5-Achs- Bearbeitungszentren

- PalettenautomationMARATHON, INDUMATIK, EROWA

- WerkstückautomationBMO, ROBOJOB, LANG, PROMOT

- Linearverkettungmit dem einzigartigen „Twinner“-Konzept

- WerkzeugautomationSTANDBY-MAGAZIN

- Automation + TILTENTABearbeitungszentren mit Schwenkspindel und NC-Rundtisch

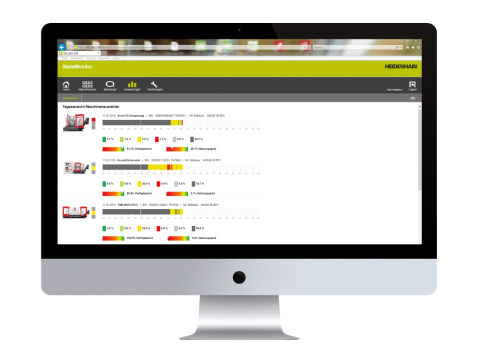

- AutomationsschnittstellenStandardschnittstellen zur Automation

- Automation + ACURA/FORTE3- und 5-Achs- Bearbeitungszentren

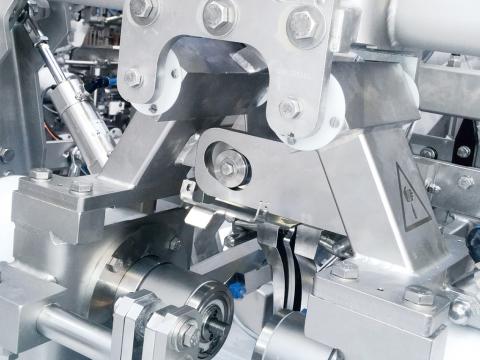

- Technik

- Einsatzgebiete

- Maschinen- und Anlagenbau

- Werkzeug- und Formenbau

- Lohnfertigung

- Lebensmittel- und Verpackungstechnik

- Landmaschinentechnik

- Kunststofftechnik

- Luft- und Raumfahrt

- Automotive

- Prozesstechnik

- Energie- und Umwelttechnik

- Medizintechnik

- Schiffbau und Schiffstechnik

- Schienenfahrzeuge und Gleistechnik

- Forschung und Bildung

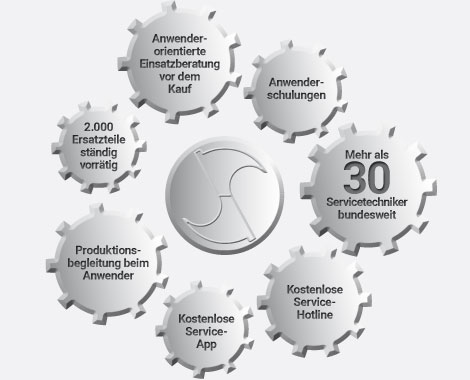

- Service

- Unternehmen

- Karriere