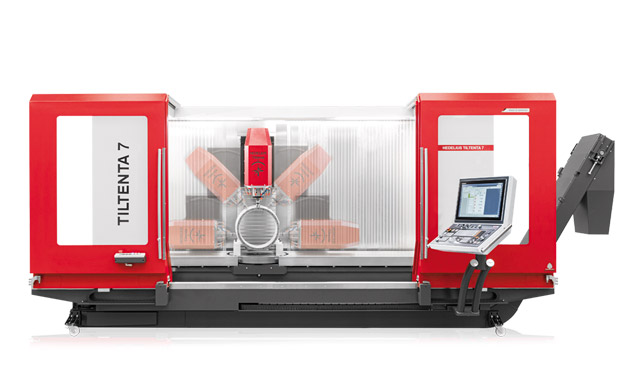

As the supplier of over 3,000 3 and 5-axis machining centres, HEDELIUS is very proud to be one of the leading German CNC machine brands and one of the most renowned CNC machine suppliers in Europe.

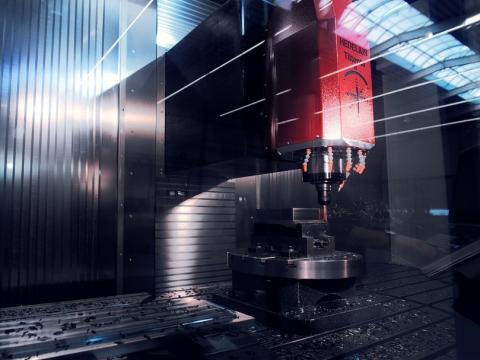

With more than 50 years of experience, we deliver exactly the quality you would expect from a genuine German milling machine: cutting-edge technology, maximum precision, durability and reliable economy in operation. Offering diverse machining solutions for tool and mould making, the aviation industry and many other areas of application, we cover a wide range of requirements and stand by our customers as a system partner: because we not only offer you durable CNC machining centres, but also provide the right accessories, e.g. automation solutions for 5-axis machining centres. All from a single source.

For us, the label “Made in Germany” embodies a philosophy that is reflected in each and every one of our machining centres and for which we stand by with conviction. All essential machine components are manufactured in-house at our production site in the city of Meppen.