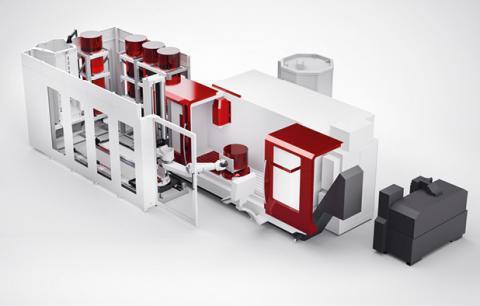

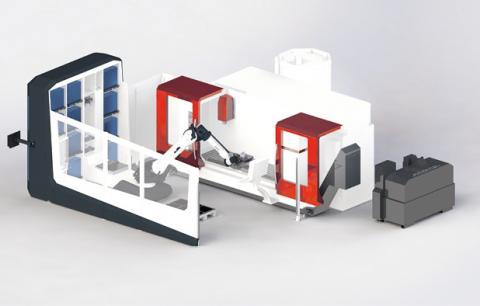

The demand for automation solutions is constantly increasing. In recent years, numerous machining centres from the ACURA series have been successfully equipped with pallet handling systems or robots. The demand for automation solutions for our TILTENTA machining centres is now also increasing.

TILTENTA machining centres are characterised by their high degree of universality in combined 5-axis and long part machining and are primarily used in single part and small series production. Through additional automation, our customers pursue the goal of utilising the machine and the available space with maximum productivity, e.g. through automatic operation in an additional shift or even at the weekend.