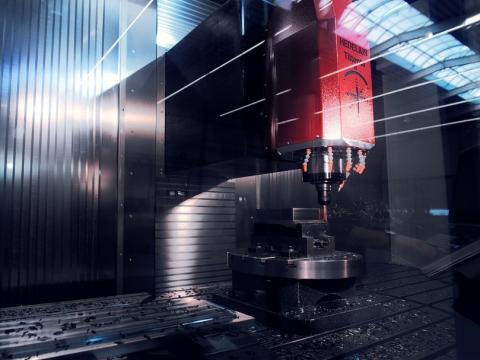

- Machining centres

- Automation

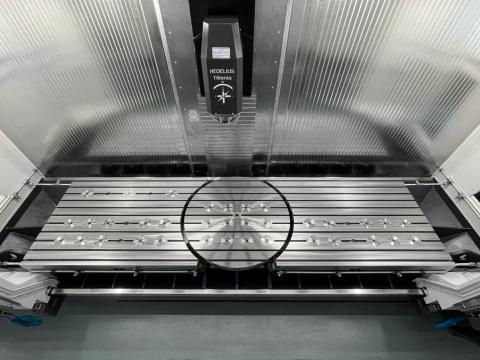

- Automation + ACURAMachining centres with a swivel rotary table

- Pallet automationMARATHON, INDUMATIK, EROWA

- Workpiece automationBMO, ROBOJOB, LANG

- Linear chain linkingLinear chain linking with ACURA 5-axis machining centres

- Tool automationStandby magazine

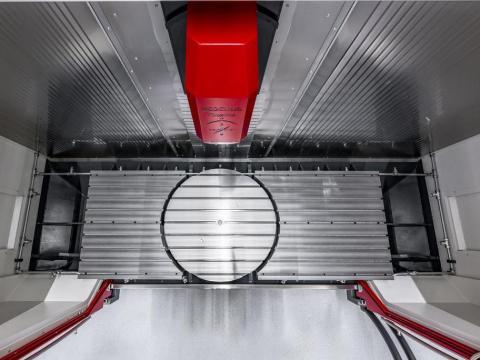

- Automation + TILTENTAMachining centres with pivoting spindle and NC rotary table

- Automation interfacesInterface solutions for automation

- Automation + ACURAMachining centres with a swivel rotary table

- Technology

- Areas of application

- Mechanical engineering

- Tool and mould making

- Contract manufacturing

- Food and packaging technology

- Agricultural engineering

- Plastics engineering

- Aecronautical and aerospace engineering

- Automotive industry

- Process technology

- Power engineering

- Medical engineering

- Shipbuilding and ship engineering

- Rail vehicles and rail technology

- Research and education

- Customer service

- Company