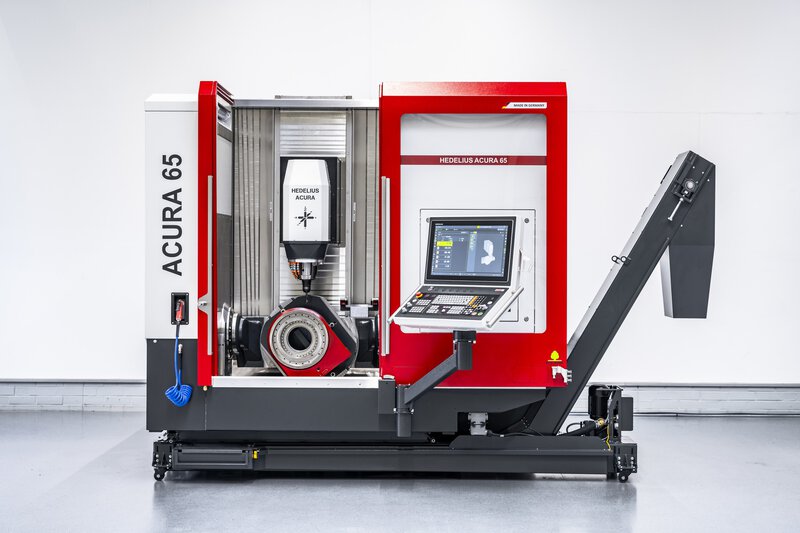

Machining centre with rotating/swivelling table: ACURA 65

The ACURA 65 high-performance machining centre impresses wherever workpieces need to be machined from several sides with high precision and in the tightest of spaces. Thanks to its low overall depth and low overall height, the 5-axis milling machine can be integrated into almost any workshop. Thanks to the extensive range of accessories, the machine can be adjusted to suit many machining tasks.

Your advantages with the ACURA 65

- Large Z travel path of 600 mm

- Rotating/swivelling table with bearings on both sides for high-precision cutting performance

- 65- or 90-position tool magazine can be operated from the front

- Complete enclosure of the ACURA 65 work area for a clean working environment

- Contact surface moved to the front for improved accessibility

- Low overall height, low installation depth

- 5-axis simultaneous milling optional

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

ACURA 65

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 700 x 650 x 600 mm | - | - | |||

| Swivelling area | ||||||

| Swivelling area | +30° – -115° | - | - | |||

| Output | ||||||

| Output | 22 / 29 / 50 / 35 / 30 kW | - | - | |||

| Speed range | ||||||

| Speed range | 14000 / 15000 / 18000 / 22000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 40, BT 40, HSK A63 | - | - | |||

| Capacity | ||||||

| Capacity | 65 / 90 / 135 / 180 / 245 / 329 | - | - | |||

| Dimensions rotating/swivelling table | ||||||

| Dimensions rotating/swivelling table | Ø 650x540 mm | - | - | |||

| Load rotating/swivelling table max. | ||||||

| Load rotating/swivelling table max. | 500 kg | - | - | |||

| Collision area diameter | ||||||

| Collision area diameter | Ø 700 mm | - | - | |||

Gallery.

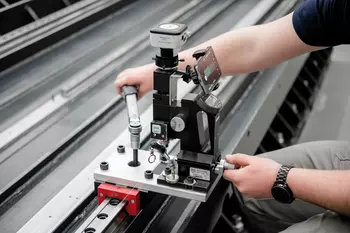

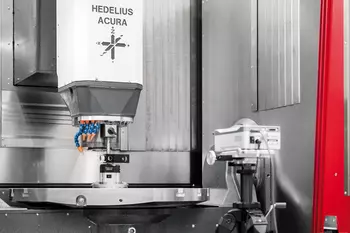

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.