Modern control technology.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum ease of use and unlimited functionality. You decide which system you want to work with.

Customisable for your success.

Various optional features for HEDELIUS machining centres.

Other optional features.

Optimise your HEDELIUS machining centre with a wide range of optional features that are precisely tailored to your specific requirements and production tasks. By making the right choice, you can avoid unnecessary downtimes, reduce production costs and increase efficiency. Standardised and optimised processes help to make better use of resources such as time and energy and permanently improve the quality of your products.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum ease of use and unlimited functionality. You decide which system you want to work with.

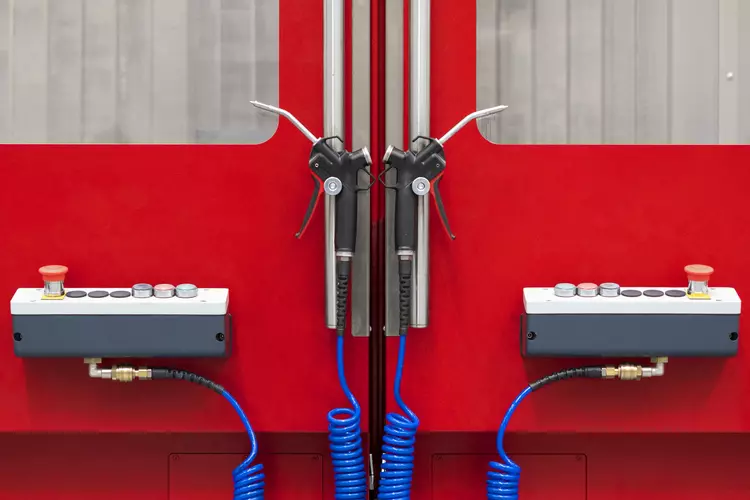

In addition to manually activated blow-off and rinsing pistols for removing chips and blowing workpieces dry, the CNC machining centres can also be equipped with additional rinsing nozzles.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre. With the help of a wide range of additional equipment options, a Coolant system can be customised to your individual machining task.

HEDELIUS uses liquid-cooled direct drive spindles, so-called motor spindles, in its machining centres. Depending on the machining task, you can choose between different spindle designs from 8,000 to 24,000 rpm with outputs of up to 50 KW, as well as between SK or HSK variants.

Motor-activated workspace doors on your CNC milling machine increase ease of use for your employees. Automatic doors are particularly recommended for short workpiece runtimes to reduce the workload on your employees.

Whether classic red, elegant white, bright blue or neutral anthracite - determine the appearance of your new machine to match your company and make a statement to your employees and customers as a modern manufacturing company.

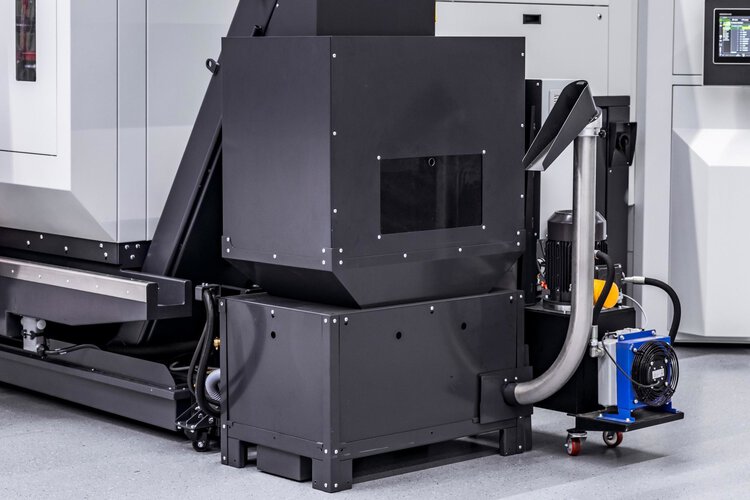

A chip press, which is connected to your CNC machining centre, separates the chips from the cooling lubricants and compresses them into clean, manageable briquettes. This reduces logistics costs, saves valuable resources, generates additional revenue and protects the environment.

Are you interested in our CNC machining centres or do you have questions about our products? Our team of experienced experts will be happy to help you find the right machining centre for your requirements and work with you to discover the potential of our CNC solutions.

Use the contact form below or write to us directly at info@hedelius.de. Our staff will get back to you as soon as possible.

We look forward to closing a dialogue with you soon!

Extremely compact 5-axis high-performance machining centres with rotating/swivelling table mounted on both sides for high-precision cutting performance.

X: 500 mm | Y: 550/370 mm | Z: 550 mm

Ø 550 mm Sturgeon circuit | max. 300 kg

SK40 / BT40 / HSK A63

The ACURA 50 offers greater precision on a smaller footprint. The constantly guided Y-axis in conjunction with the solidly ribbed feed carriages made of grey cast iron reduce vibrations. The rotating/swivelling table is bearing-mounted on both sides and the Z-axis is specially protected against heat distortion. These and many other details increase the quality of machining, while the dimensions of the 5-axis machining centre are extremely small thanks to the special design.

The machine is loaded through an approx. 600 x 840 mm opening in the right-hand side of the machine. This pneumatically activated stainless steel door of the 5-axis machining centre enables automatic loading of pallets without restricting access to the Machine work area.

The ACURA 50 MARATHON is already prepared for pallet automation at the factory with a permanently installed zero point clamping system and a pneumatically activated loading opening on the right-hand side of the machine. Depending on the variance of the workpiece spectrum, different tool magazines with up to 319 tool positions and main spindles up to 18,000 rpm are available.

X: 700 mm | Y: 650/465 mm | Z: 600 mm

Ø 700 mm Sturgeon circuit | max. 500 kg

SK40 / BT40 / HSK A63

The ACURA 65 high-performance machining centre impresses wherever workpieces need to be machined from several sides with high precision and in the tightest of spaces. Thanks to its low overall depth and low overall height, the 5-axis milling machine can be integrated into almost any workshop. Thanks to the extensive range of accessories, the machine can be adjusted to suit many machining tasks.

The ACURA 65 EL enables manufacturer-independent automation of production using a pallet handling system or a robot from the left-hand side of the machine. This enables unmanned automated production. The door of the 5-axis machining centre remains fully accessible for the manual production of single parts.

The ACURA 65 MARATHON comes with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS MARATHON pallet magazine systems in the series. The ACURA 65 MARATHON remains accessible from the front, even with automation, and the view from the Loading station to the work area is unobstructed. The machining centre has a 65-place tool magazine as standard. As an option, a MAGNUM magazine provides a further 25 tools and a standby magazine provides a further 264 tools.

X: 900 mm | Y: 850/600 mm | Z: 700 mm

Ø 900 mm Sturgeon circuit | max. 1000 kg

SK40 / BT40 / HSK A63

The ACURA 85 offers greater precision on a smaller footprint. The constantly guided Y-axis in conjunction with the solidly ribbed feed carriages made of grey cast iron reduce vibrations. The rotating/swivelling table is bearing-mounted on both sides and the Z-axis is specially protected against heat distortion. These and many other details increase the quality of machining, while the dimensions of the 5-axis machining centre are extremely small thanks to the special design.

The advantage of the ACURA EL concept is that loading from the side allows full access to the work area for set-up and control work, but also for single part production during the day shift, for example. Even crane loading of the machine is possible without restrictions. Another advantage of the 5-axis machining centre (depending on the selected automation) is the visibility of the work area and thus optimised process control during set-up on the automation.

The ACURA 85 MARATHON comes with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS MARATHON pallet magazine systems in the series. Even with automation, the ACURA 85 MARATHON remains accessible from the front, with a clear view of the work area from the loading station. The machining centre has an 80-place tool magazine as standard. An additional 264 tools are optionally available by connecting a standby magazine.

Versatile machining centres with infinitely variable swivelling main spindle and integrated NC rotary table.

X: 2000/2600/3600 mm

Y: 700 mm | Z: 695/735 mm

Ø 1050 mm Sturgeon circuit | max. 800 kg

SK40 / BT40 / HSK A63

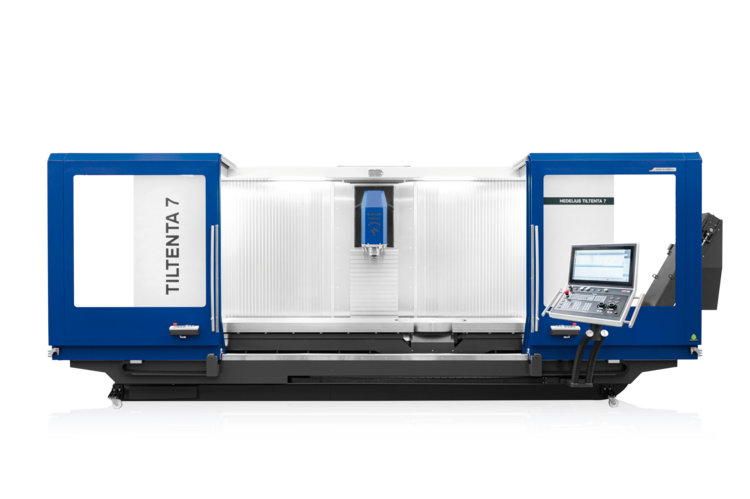

Compact and automatable - these two terms characterise the TILTENTA 7-2000 NEO. With a 2,000 mm X travel path, the infinitely variable swivelling main spindle and the integrated 5-axis rotary table for workpieces up to 800 kg and 1,050 mm diameter, HEDELIUS offers an uncompromising universal machining centre. Whether aluminium, grey cast iron or tool steel - with this CNC machining centre you can release a wide range of machining tasks in machine, tool and vehicle construction. The many automation solutions are another highlight.

The TILTENTA 7 NEO opens up new areas of application in the machining of single parts and series. Whether end processing of long workpieces or 5-side complete processing with integrated NC rotary table - the TILTENTA 7 crossover concept releases many machining tasks in machine, tool and vehicle construction. The combination of a continuously swivelling main spindle and a long machine table with integrated NC rotary table allows the mixed production of large workpieces and precise 5-axis machining in one machine.

The TILTENTA 7-2600 NEO EL opens up new areas of application for the fully automated machining of single parts and series. Open interfaces and a laterally offset NC rotary table allow an automation system to load the TILTENTA 7 from the left-hand side of the machine. The combination of the infinitely variable swivelling main spindle and the long machine table with integrated NC rotary table allows the mixed production of large workpieces and precise 5-axis machining in one machine.

The equipment with one or two integrated heavy-duty NC rotary tables (optional) and a work area partition enables economical series production of large and heavy workpieces. Changing from one work area to the other in oscillation mode only takes approx. 10 seconds. By simply removing the partition, the entire work area is available for vertical machining of workpieces up to 3600 mm in length.

X: 2600/3600/4600/6200 mm

Y: 900 mm | Z: 900/1005 mm

Ø 1250 mm Sturgeon circuit | max. 1800 kg

SK40 / BT40 / HSK A63

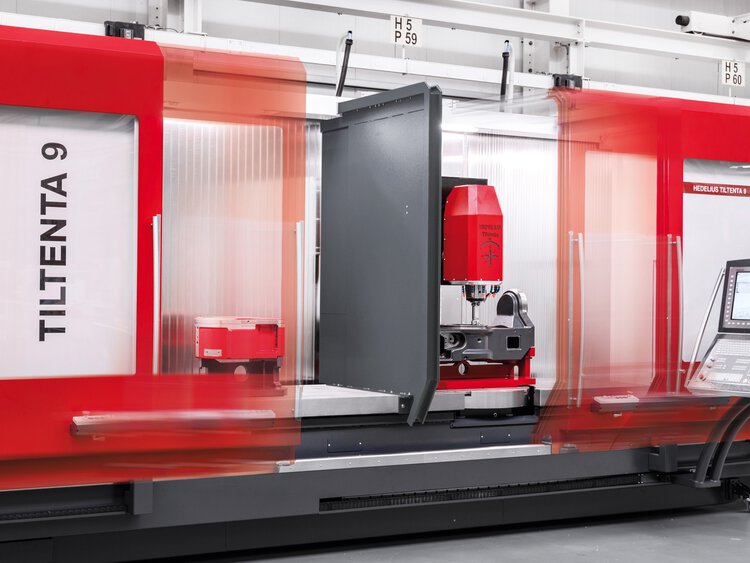

The TILTENTA 9-2600 travelling column machining centre is fully enclosed and also allows unrestricted crane loading. The machine is equipped with a Heidenhain TNC control system with touch display, full keyboard and rapid motion potentiometer as standard. A Sinumerik ONE / 840 D sl is available as an option.

The TILTENTA 9-3600 travelling column machining centre enables speeds of up to 18,000 rpm and spindle outputs of up to 50 kW with a torque of up to 217 Nm. Four axes in the tool guarantee workpiece-independent dynamics - an ideal prerequisite for high rapid motions and feeds of up to 40 m/min.

With travel paths of 4600 x 900 x 900 mm (x/y/z), the TILTENTA 9-4600 offers plenty of space for a wide range of machining tasks. Be it for the vertical machining of workpieces up to 4600 mm in length or for the economical 3- and 5-axis machining of series parts in oscillation mode.

With travel paths of 6200 x 900 x 900 mm (x/y/z), the TILTENTA 9-6200 offers plenty of space for a wide range of machining tasks. Be it for the vertical machining of workpieces up to 6200 mm in length or for the economical 3- and 5-axis machining of series parts in oscillation mode.

X: 2600/3600/4600/6200 mm

Y: 1000 mm | Z: 1000/1165 mm

Ø 1450 mm Sturgeon circuit | max. 2200 kg

SK50 / BT50 / HSK A100

The TILTENTA 10 with travel paths of 2600 x 1000 x 1165 (X/Y/Z) is ideal wherever heavy-duty chipping in machine and tool construction opens up tight spaces. The integrated heavy-duty rotary table allows workpieces weighing up to 2,200 kg to be machined. The standard equipment with the SK50 BIG PLUS duplex contact spindle system (optional: HSK A100) is another highlight of this stable all-rounder.

HEDELIUS has always aspired to build stable machining centres for a wide range of applications. With the TILTENTA 10, we are rounding off the successful TILTENTA series, which has been built hundreds of times. With travel paths of 3600 x 1000 x 1000 (X/Y/Z) and an integrated heavy-duty rotary table up to 1,600 kg / 2,200 kg (optional) table load, this machine will also set standards in machine and tool construction. The TILTENTA 10 is equipped with the SK50 BIG PLUS duplex contact spindle system as standard (optional: HSK A100).

A travelling column machining centre offers clear advantages in single parts and small series production thanks to the ability to produce cubic workpieces in 5 axes, but also to machine long parts vertically or from the end faces. The travel path in the X-axis is therefore an essential criterion when selecting the right machine. The TILTENTA 10-4600 impresses with travel paths of 4600 x 1000 x 1000 (X/Y/Z) and the integrated heavy-duty rotary table up to 1,600 kg / 2,200 kg (optional) table load in machine and tool construction. The TILTENTA 10 is equipped with the SK50 BIG PLUS duplex contact spindle system as standard (optional: HSK A100).

For long and heavy workpieces, a HEDELIUS 5-axis travelling column machining centre from the TILTENTA 10 series plays all the trump cards. Full 5-axis machining up to 2,200 kg, vertical machining up to 6,200 mm, front side processing up to approx. 5,000 mm, oscillating machining, SK50 power - and all this with constant machine dynamics, regardless of the workpiece weight. Thanks to the travelling tool magazine, you as the user benefit from short chip-to-chip times over the entire travel path. Thanks to the numerous accessories such as pick-up magazines for extra-long tools or vertical rotary tables for shaft machining, this machine can be used flexibly and enables you to achieve optimum capacity utilisation and a quick return on investment.

X: 2600/3600/4600/6200 mm

Y: 1100 mm | Z: 900/1005 mm

Ø 1450 mm Sturgeon circuit | max. 1800 kg

SK40 / BT40 / HSK A63

With an impressive 1,100 mm Y travel path, the TILTENTA-11 series from HEDELIUS is entering new dimensions. The TILTENTA 11-2600 opens up new areas of application in the machining of single parts and series in machine, tool and vehicle construction. Whether for machining long workpieces or 5-side complete processing with an integrated NC rotary table - the TILTENTA crossover concept releases many tasks. The combination of a continuously swivelling main spindle and a long machine table with integrated NC rotary table allows the mixed production of large workpieces and precise 5-axis machining in one machine.

With 4 axes in the tool, the TILTENTA 11 impresses with excellent dynamics, regardless of the workpiece weight, creating ideal conditions for high rapid motions of up to 40 metres per minute. Equipped with powerful, liquid-cooled CELOX motor spindles, this 5-axis machining centre impresses with its high cutting output and precision. The large X-axis, Y-axis and Z-axis as well as the rigid machine bed set standards.

Thanks to the travelling tool magazine of the TILTENTA 11, tool changes only take a few seconds despite the 4600 mm travel path. The standard 65-cavity tool magazine already reduces your tooling times as standard. With a work area partition, the machine can also be loaded in oscillation mode during machining. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 5-axis machining centre.

Thanks to the travelling tool magazine of the TILTENTA 11, tool changes only take a few seconds despite the 6200 mm travel path. The standard 65-position tool magazine already reduces your tooling times as standard. With a work area partition, the machine can also be loaded in oscillation mode during machining. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 5-axis machining centre.

Discover the FORTE series - a new class of vertical 3-axis machining centres that offer maximum precision and performance in the smallest of spaces with state-of-the-art Operator's platform design.

X: 1120 mm | Y: 550 mm | Z: 550 mm

SK40 / BT40 / HSK A63

With the optional zero-point clamping systems, the tooling times of the

FORTE 50 Single 1120 can be significantly reduced. They are a useful addition, especially for single parts to medium series production.

The FORTE 50 EL has a pneumatic

actuated loading opening on the right-hand side as standard. This enables automatic loading of pallets or workpieces without

restricting access to the Machine work area.

X: 1320 mm | Y: 650 mm | Z: 600 mm

SK40 / BT40 / HSK A63

When high cutting performance and precision are required in the smallest of spaces, the FORTE 65 Single 1320 3-axis machining centre is the right choice. The modern Operator's platform design impresses with its high dynamics, regardless of the workpiece weight. With travel paths of 1320 x 650 x 600 mm, the travelling column machining centre offers a surprising amount of space with small installation dimensions. Direct position measuring systems on all axes and the latest generation of drive technology ensure long-term precision.

If high cutting performance and precision are required to implement your automation project, the FORTE 65 EL 3-axis machining centre is the right choice. The modern Operator's platform design impresses with its high dynamics, regardless of the workpiece weight. The machine has a pneumatically activated loading opening on the left-hand side as standard. This enables automatic loading of pallets or workpieces without restricting access to the Machine work area. The large selection of interfaces for different automation manufacturers such as EROWA, INDUMATIK or BMO opens up countless automation options.

X: 1620 mm | Y: 850 mm | Z: 700 mm

SK40 / BT40 / HSK A63

The large machine window and the fixed machine table ensure that everything is open to the operator so that the work area can be optimally utilised. Direct access to the workpiece is further supported by the ergonomic working height of the machine table. Vertical stainless steel covers ensure optimised chip fall - even when machining aluminium in bulk. This means that little time is spent on cleaning when working with the precise 3-axis milling machine.

X: 2000/2600/3600 mm

Y: 700 mm | Z: 800 mm

SK40 / BT40 / HSK A63

Where conventional CNC machining centres with a moving table reach their technical limits in terms of travel paths, dynamics, table load and chip removal, the FORTE 7 series offers a solution. The Operator's platform design impresses with its high table load, consistent dynamics (regardless of workpiece weight) and optimised chip fall. The closed full cabin and integrated exhaust system ensure a clean working environment. The sliding control panel and the large viewing windows make set-up and process control easier for the operator.

The FORTE 7-2600 NEO 3-axis machining centre opens up new areas of application for the machining of single parts and series. By inserting a work area partition, the long basic work area can be divided in two for loading and unloading during machining. This enables productive oscillating machining.

The travelling column concept of the 3-axis machining centre with bottom-mounted cast iron bridge offers ideal conditions for high rapid motions and feeds of up to 40 m/min. Liquid-cooled motor spindles with speeds of up to 18,000 rpm and outputs of up to 35 kW ensure high cutting performance with uncompromising precision.

X: 2600/3600/4600/6200 mm

Y: 900 mm | Z: 1005 mm

SK40 / BT40 / HSK A63

The FORTE 9 3-axis machining centre extends the successful FORTE series from HEDELIUS upwards. Designed for chipping with modern high-performance tools, the FORTE 9-2600 has a 60-fold tool magazine and large travel paths of 2600 x 900 x 1005 mm. The sophisticated travelling column concept impresses with its impressive output, precision and dynamics when machining large parts.

The travelling 60-position tool magazine guarantees tool changes in a matter of seconds. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 3-axis machining centre.

The travelling column concept of the 3-axis machining centre demonstrates its superiority particularly with large and heavy workpieces, as the dynamics of the machine are independent of the workpiece weight. The torsion-resistant travelling column made of grey cast iron impresses with its high stability and vibration damping.

The FORTE 9-6200 sets new standards in the processing of large workpieces. With a travel path of 6,200 mm, outstanding dynamics and a stable travelling column made of grey cast iron, it guarantees maximum precision and vibration damping - even for heavy-duty tasks. Ideal for demanding production processes.

X: 2600/3600/4600/6200 mm

Y: 1000 mm | Z: 1165 mm

SK50 / BT50 / HSK A100

When high output is required in a small space, the FORTE 10-2600 3-axis vertical machining centre is the first choice. Thanks to the high-quality standard equipment with direct measuring systems, stainless steel slats, smooth-running work area doors and the powerful milling spindle with SK50, BT50 or HSK A100 tool holder, you can produce precisely and economically.

The FORTE 10-3600 is an impressive 3-axis vertical machining centre with extra-large travel paths, a particularly powerful milling spindle with SK50, BT50 or HSK A100 tool holder, a 40-position tool magazine as standard and an extensive range of accessories. This machining centre will become the productive centre of your production.

Thanks to the extensive range of accessories such as rotary tables, vacuum pumps, pick-up magazines for extra-long tools or a hydraulic clamping system for the automatic activation of devices, we can customise the FORTE 10 series to meet your individual requirements. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of these high-performance vertical machining centres.

With a 6200 mm X travel path, this machining centre rounds off the successful FORTE 10 series. Generously dimensioned recirculating roller guides, polished ball roller spindles and direct Heidenhain measuring systems in all axes guarantee outstanding rigidity combined with maximum accuracy and dynamics. The travelling column and machine table are made of heavy grey cast iron. This is an essential criterion for an SK50/HSK 100 machine to ensure high surface quality and low tool wear even in difficult-to-machine materials. Thanks to the extensive range of accessories such as rotary tables, vacuum pumps, pick-up magazines for extra-long tools or a hydraulic clamping system for the automatic activation of devices, we can customise the FORTE 10 series to meet your individual requirements.

X: 2600/3600/4600/6200 mm

Y: 1100 mm | Z: 1005 mm

SK40 / BT40 / HSK A63

With the FORTE 11, HEDELIUS Maschinenfabrik is setting another benchmark in 3-axis machining. With a Y travel path of 1100 mm, the machining centre expands the popular FORTE series. With 65 tools as standard and travel paths of 2600 x 1100 x 1005 mm (x/y/z), this machine is particularly suitable for chipping solid parts or machining several small parts.

The FORTE 11-3600 3-axis machining centre impresses with its wide range of applications in various industries. Whether machine or tool construction, vehicle construction or aerospace - the FORTE series from HEDELIUS sets standards wherever long workpieces are machined economically with high precision. With the powerful milling spindles, a 65-position tool magazine as standard and the extensive range of accessories, this machining centre will become the productive centre of your production.

Despite a travel path of 4600 mm, tool changes on the FORTE 11-4600 take just a few seconds. The large, travelling 65-cavity tool magazine also reduces your tooling times as standard. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 3-axis machining centre.

Maximum precision with a large travel path: The FORTE 11-6200 impresses with an impressive travel path of 6200 mm and a quick tool change in just a few seconds. The travelling 65-position tool magazine significantly reduces tooling times. Perfectly designed work areas with vertical slat covers and excellent accessibility offer ideal working conditions.

for CNC machining centres

Increase the accuracy of your production with the help of advanced touch probes and lasers.

By using a partition in your machining centre, two closed, independent work areas for chipping in oscillation mode can be created from one work area.

The machine table is equipped with a standardised interface that reduces the centring and alignment of devices to just a few seconds.

To extend the range of applications of your TILTENTA from 5-sided machining to 5-axis simultaneous processing.

Attachment rotary tables to extend the axes and increase the performance spectrum of your CNC machining centre.

Enable multi-sided machining with multiple clamping and thus rationalise series production.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres.

Ensuring a technological edge: High-output and high-torque CELOX integral motor spindles with hybrid bearing technology.

Increased operating comfort and relief for machine operators.

HEDELIUS offers a paint finish for the work area doors of all machines according to your colour requirements.

A chip press separates chips from cooling lubricants and compresses them into clean, manageable briquettes.

Machining centres direct from the manufacturer. Very short delivery time!

Find the right CNC machining centre for you.

Automation solutions and open interfaces for third-party providers to increase efficiency.

+ Automation of machining centres with rotating/swivelling table

+ Lateral loading by the automation system

+ Work area remains fully intact

+ Solutions with low space requirements

+ Automation of long-bed milling machines with swivelling spindle

+ Front loading through the automation system

+ Work area remains intact

+ Solution for 5-axis and long part machining

+ Automation of 3-axis milling machines

+ Lateral loading through the automation system

+ Work area remains fully intact

+ Solutions with low space requirements

Automation solutions for single parts as repeat parts or small to medium series with pallets.

With six pallets measuring up to 400 x 500 mm and a maximum transfer weight of 370 kg, the super-compact MARATHON PL406 pallet magazine is a space-saving productivity booster for the ACURA series. For easy operating, the automation system has buttons for rotating the pallet carrier and for acknowledging raw parts. The job list is created on the HEIDENHAIN control system in the Batch Process Manager.

With up to 34 pallets, the MARATHON RZ430 multi-pallet magazine is ideal when single parts need to be produced as repeat parts or small to medium series. Pallet handling is performed by a 6-axis YASKAWA robot with a load capacity of 88 or optionally 110 kg. Two pull-out storage/retrieval stations guarantee maximum productivity even with short program runtimes. The highlight is the MultibatchOS pallet and order management system with an 18.5" widescreen touch display. The automation system is perfectly open to the ACURA 50 and ACURA 65 5-axis machining centres.

With 22 pallets, the MARATHON SR422 multi-pallet magazine is ideal for producing single parts as repeat parts or small to medium series. One highlight is the consistent operating concept of the ACURA 65 MARATHON with Heidenhain TNC - at the machine, at the tool terminal of the standby magazine and at the pallet magazine terminal. The automation system is perfectly open to the ACURA 65 5-axis machining centre.

With 18 pallets of 500 x 500 mm each, 700 mm interference circle and 470 kg transfer weight, the MARATHON SR518 multi-pallet magazine is designed for handling large, heavy single parts as repeat parts or small to medium series. The powerful ACURA 85 5-axis machining centre, the optional 50 kW spindle and a 344-position STANDBY tool magazine form a perfectly coordinated team for maximum productivity. The operator can keep an eye on the machine's work area at all times from the 360° rotating storage/retrieval station. The work area remains fully accessible from the front for process control and loading new workpieces.

The TILTENTA series is known for its flexibility,

reliability and cutting performance. The new

TILTENTA 7-2000 NEO offers generous travel paths

of 2000 mm in the X-axis, 700 mm in the Y-axis

and 735 mm in the Z-axis. The pallet magazine

has 15 pallet locations for components with a diameter of up to

700 mm and a clamping height of 500 mm.

The storage/retrieval station can also be rotated so that clamping towers or clamping pyramids, for example,

can be ergonomically

tooled. For full flexibility, the MARATHON SR415 loads the TILTENTA 7 fully automatically from

the left-hand side of the machine.

The EROWA ERC 80 loads the ACURA 50 EL 5-axis machining centre with 320 x 320 mm pallets. The multi-pallet magazine has a capacity of 10 pallets of 320 x 320 mm each (optionally 16 pallets), with a transfer weight of 80 kg. Alternatively, the pallet magazine can also handle smaller pallets, e.g. up to 24 pallets with a diameter of 210 mm. The special feature of this concept is the small space requirements of approx. 4480 mm.

Just as much as necessary. That is the concept behind the EROWA Robot Dynamic 150L. You only procure as much automation as is currently required. If the production capacity requirements change, the Robot Dynamic system can be expanded modularly at any time. The slim linear rail is extended to the required length using individual segments. The magazine levels are configured specifically for the task at hand.

The EROWA Leonardo is a pallet handling device with multi-level magazines. The transfer weight is 80 kg (optional features 120 kg). The X-axis has a long travel path and therefore also reaches into large machines. The few necessary commands are entered via a touchscreen pad. The integrated control has a high degree of autonomy. Pallets are automatically placed in an available position.

With the INDUMATIK Light 30, the machining centre can be quickly and easily converted from manual to automated operation. With 50 pallet locations for different workpieces, the ACURA can also be operated in unmanned shifts. The integrated storage and retrieval station allows the operator to remove finished parts at any time and load them with new parts at the same time. The optional InduCell control software checks the NC programs and the tool table to ensure continuous chipping.

With the INDUMATIK Light 60, the machining centre can be quickly and easily converted from manual to automated operation. With 24 pallet locations for different workpieces, for example, the HEDELIUS ACURA can also be easily operated in unmanned shifts. The integrated ergonomic storage and retrieval station allows the operator to remove finished parts at any time and load them with new parts at the same time. The optional InduCell control software checks the NC programs and the tool table to ensure continuous chipping.

With the INDUMATIK Light 120, the machining centre can be quickly and easily converted from manual to automated operation. With 30 pallet locations for different workpieces, for example, the HEDELIUS ACURA can also be operated in unmanned shifts. The integrated storage and retrieval station allows the operator to remove finished parts at any time and load them with new parts at the same time. The optional InduCell control software checks the NC programs and the tool table to ensure continuous chipping.

Designed as a flexible manufacturing system (FMS for short), the Indumatik 150 allows both the automation of a machining centre and the automation of a multi-machine system. The Indumatik 150 has a flexibly expandable pallet storage system and a rotating handling device that can be moved on a floor rail. Clamping of the workpieces

Robot cells manage workpieces from grid drawers fully automatically for small and medium batch production.

The Iridium Hybrid from BMO combines two worlds in the automation of a CNC machining centre: flexible automation of small series using devices with pallets and series production of e.g. sawing sections by inserting workpieces directly into the machine. The Iridium impresses on the one hand with its compact dimensions of just 1,500 mm in width and on the other with a capacity of 20 pallets measuring 200 x 200 mm and a storage drawer for 50 workpieces measuring up to 100 x 100 mm.

The Platinum robot cell is suitable for loading workpieces onto up to two CNC machines. The workpieces are removed from grid drawers by a 6-axis robot and inserted into the machine. In order to be able to react very flexibly to small batch sizes and increase the unmanned running time of the system, the Platinum automation solution also has eight pallet locations for holding the clamping devices. This means that the robot automation first automatically inserts the required clamping device into the machine and then tools the device from the storage drawer with the raw parts.

The Titanium model has up to 100 pallet magazine locations and two pallet loading stations to process workpieces or pallets in combination. Robots weighing 180 kg or 225 kg are available to ensure that even heavy workpieces can be processed on pallets. To remove the high chip volume, the machines in the ACURA series can be equipped with special accessories such as work area rinsing and alternative chip conveyors.

While the number of workpieces that can be processed in the robot cells of the Platinum and Titanium series is limited by the number of drawers, the robot cells of the Infinity series can accommodate an almost unlimited number of workpieces and pallets. This is made possible by flexibly divisible shelves and integrated height control for optimum utilisation of the shelf capacity. The workpieces are stored on grid trays. In order to be able to react very flexibly to small batch sizes, heavy parts or complex clamping situations, the Infinity solution has pallet locations for holding a wide variety of clamping devices. As true multi-batch automation, the robot first automatically inserts the required clamping device into the machine and then tools the device from the trays with the raw parts.

This beginner-friendly automation system has been specially developed for tooling and unloading small series and/or small workpieces. The automation has a 6-axis robot that takes the workpieces from a fixed table and places them in the 5-axis machining centre of the ACURA series. Depending on the space available, the system can load the machine from the front or from the side.

If high flexibility and autonomy are required, the ROBOJOB Tower is worth a look. A vertical lift system stores not only workpieces but also clamping devices and pallets on up to 28 levels. As an option, the system can be equipped with additional pallet racks and a storage/retrieval station for very heavy or very large workpieces.

If high flexibility and autonomy are required, the ROBOJOB Tower is worth a look. A vertical lift system stores not only workpieces but also clamping devices and pallets on up to 28 levels. As an option, the system can be equipped with additional pallet racks and a storage/retrieval station for very heavy or very large workpieces.

The RoboTrex automation cell consists of a Fanuc 6-axis robot with payloads of up to 50 kg. The workpieces are stored using vices on mobile automation trolleys. The patented, upright mounting of the vices ensures optimised utilisation of the footprint. The automation trolleys allow workpieces to be clamped and unclamped even at a great distance from the machine. An automation trolley can be removed or exchanged during machine operation. The RoboTrex 96 system also has a gripper changer to enable different sizes of shear frames to be processed. In conjunction with the automatic recognition of the automation trolleys, the system offers a high degree of flexibility and covers a wide variety of parts.

Automation solutions that combine workpiece and pallet handling in one system

Mirror-image version of the ACURA 50 and ACURA 65 enables interlinking with pallet or workpiece systems.

Separate tool stores for up to 264 additional tools clean, maintain and reduce changeover times enormously.

Preconfigured standard interfaces, e.g. for EROWA, INDUNORM, ROBOJOB, BMO or LANG, are available for the electrical connection to an automation system.

With over 3,000 HEDELIUS machining centres installed today, we ensure precise and powerful chipping in a wide range of industries.

Various design highlights ensure that our customers can achieve maximum precision and efficiency in every production step in the long term.

By using set-up time-optimised technology, such as fast tool provision and innovative clamping devices, companies can maximise their spindle running time in the long term.

Increase the accuracy of your production with the help of highly developed touch probes and lasers.

By using a partition in your machining centre, two closed, independent work areas for chipping in oscillation mode can be created from one work area.

The machine table is equipped with a standardised interface that reduces the centring and alignment of devices to just a few seconds.

To extend the range of applications of your TILTENTA from 5-sided machining to 5-axis simultaneous processing.

Attachment rotary tables to extend the axes and increase the performance spectrum of your CNC machining centre.

Enable multi-sided machining with multiple clamping and thus rationalise series production.

The factors that have a significant influence on the accuracy of our precision machines.

Optimise your HEDELIUS machining centre with a wide range of optional features that are precisely tailored to your specific requirements and production tasks.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality.

The TNC7 combines high-quality hardware components with an advanced, customisable user interface and a generous package of functions.

With SINUMERIK ONE, you can set new standards in your production thanks to digital twins, extended diagnostic functions and a high degree of flexibility.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres.

Technologischen Vorsprung sichern: Leistungs- und drehmomentstarke CELOX-Integral Motorspindeln mit Hybrid-Lagertechnik.

Increased operating comfort and relief for machine operators.

HEDELIUS offers a paint finish for the work area doors of all machines according to your colour requirements.

A chip press separates chips from cooling lubricants and compresses them into clean, manageable briquettes.

The advancing digitalisation in the manufacturing industry is opening up completely new opportunities to make chipping processes more transparent, faster and more efficient. We at HEDELIUS also take the increasing importance of intelligent interlinking of production, quality and machine data seriously. The aim is to digitally support the entire value-added process from order planning to the finished machined component.

+ Personalised. On site nationwide.

+ Intelligent deployment planning.

+ Excellent spare parts availability.

Fast, professional solution when servicing is required.

+ Service enquiries

+ Maintenance enquiries

+ Spare parts enquiries

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

We provide a wide range of free information material in our download area.

All upcoming dates for workshops, trade fair appearances and other events at a glance.

Over 3000 well-known customers from all over Europe trust in the quality and reliability of HEDELIUS machines.

Interesting facts about the company, news, product information, user reports

For 55 years, HEDELIUS has had only one goal: to increase economic efficiency in single parts and small series production in machine, tool and vehicle construction.

Take the opportunity to experience our machining centres and automation solutions live and see their performance and safety for yourself.

Thousands of companies in Europe, including hidden champions, rely on our solutions. From SMEs to global corporations, we accompany you on the path to sustainable success.

Comprehensive and practical training for CNC programmers and operators from 3-axis to 5-axis machining.

Experience the latest developments in machining technology - either conveniently online or directly with us in Meppen.

HEDELIUS brand machining centres are used in a wide range of industries.

Conserving resources, energy efficiency and safeguarding the future: our efforts to make a positive contribution to shaping a sustainable future.

As a supplier, do you share our values of quality and reliability? Then please feel free to open a dialogue with us.

Over the years, we have built up a strong network of 17 trading partners throughout Europe.