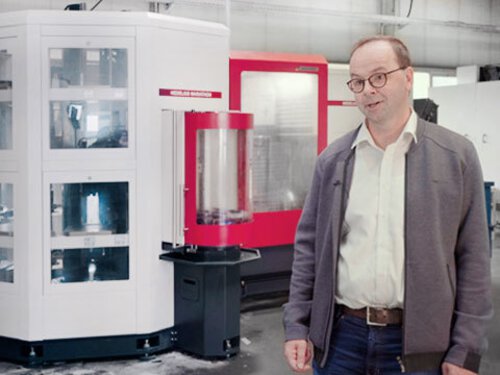

HEDELIUS machining centres in action.

Used for machining centres.

CNC machining centres are available in numerous types, including horizontal and vertical machining centres, models with fixed or movable clamping tables as well as machines for multi-sided machining or 5-axis simultaneous machining.

More than 30 years ago, HEDELIUS recognised the advantages of vertical machining centres with an Operator's platform design for single parts and small series production. This technology has been continuously developed ever since. The vertical machining centres from HEDELIUS impress with their high stability, precision, automatic tool changers with a large magazine, ergonomic design and optimised chip fall.

It is not without reason that over 3,000 manufacturing companies in Europe rely on a CNC machining centre made by HEDELIUS. In particular medium-sized companies from mechanical engineering, toolmaking, contract manufacturing, vehicle construction, the pump and fittings industry, air and space travel and plastics processing rely on the expertise of the Emsland-based technology company.

The strengths of HEDELIUS lie not only in the wide range of products and extensive accessories, but also in the comprehensive advice provided by a nationwide sales team, the large technology centre with experienced application engineers and a powerful service team.

Get a productive edge with the combination of state-of-the-art CNC machine technology, tooling optimisation, automation and fast service.

Branches.

Customer testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.

Heidkamp Metallbearbeitung in Hüllhorst** relies on maximum flexibility, quality and adherence to deadlines in the production of milled parts. The 5-axis machining centre ACURA 65 EL from HEDELIUS, combined with a large tool store, pallet pool and GRESSEL centric clamps, ensures short tooling times, automated individual and small series production and reliable processes, even with complex components and tight delivery deadlines.