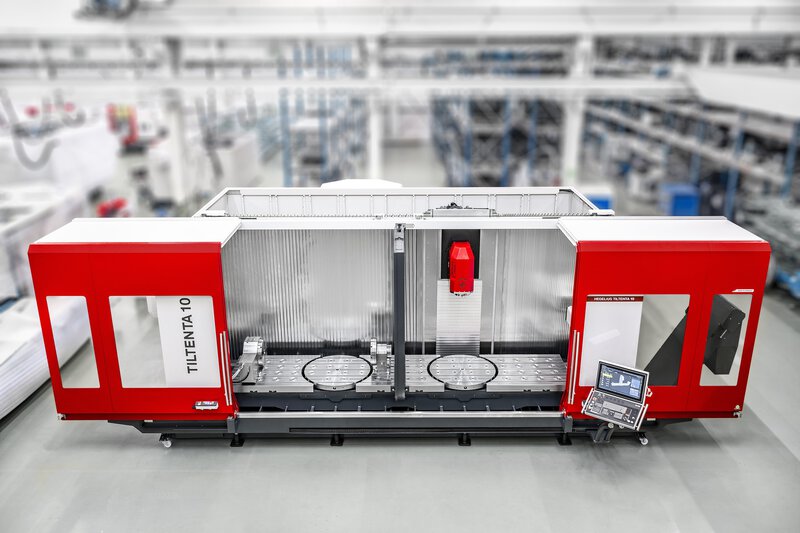

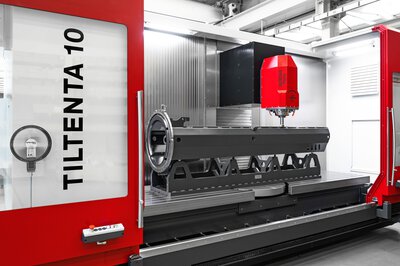

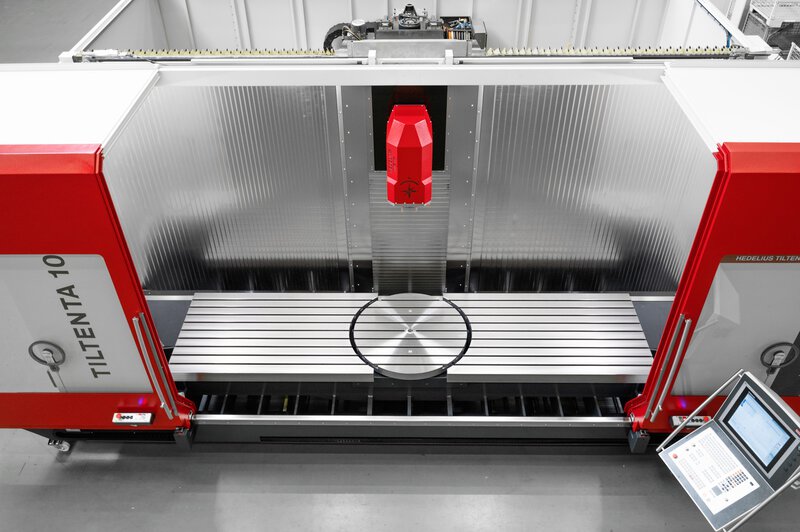

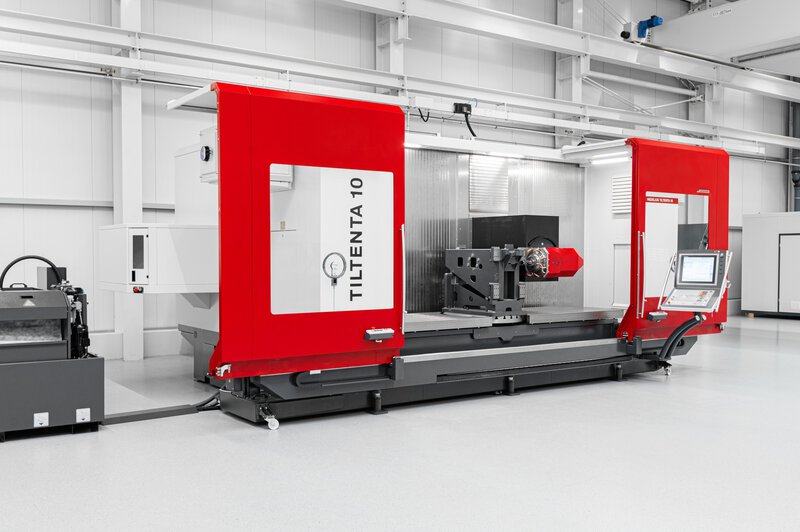

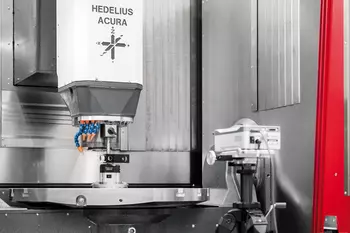

Machining centre with swivelling spindle: TILTENTA 10-4600

A travelling column machining centre offers clear advantages in single parts and small series production thanks to the ability to produce cubic workpieces in 5 axes, but also to machine long parts vertically or from the end faces. The travel path in the X-axis is therefore an essential criterion when selecting the right machine. The TILTENTA 10-4600 impresses with travel paths of 4600 x 1000 x 1000 (X/Y/Z) and the integrated heavy-duty rotary table up to 1,600 kg / 2,200 kg (optional) table load in machine and tool construction. The TILTENTA 10 is equipped with the SK50 BIG PLUS duplex contact spindle system as standard (optional: HSK A100).

Your advantages with the TILTENTA 10-4600

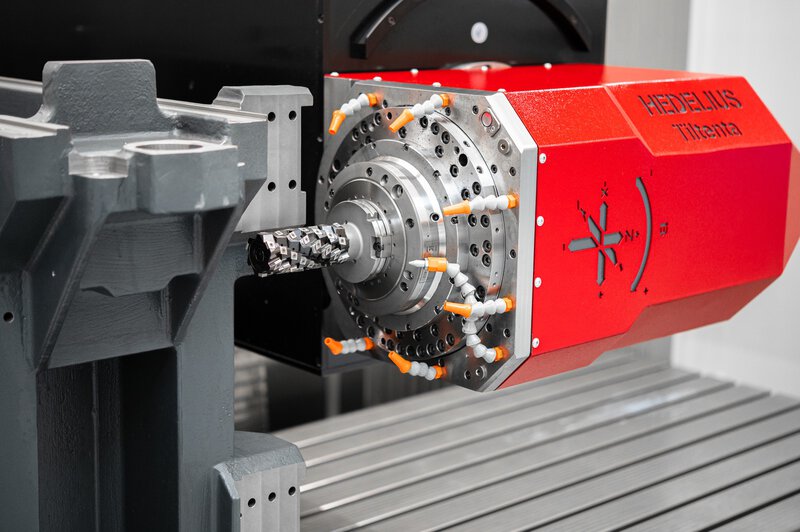

- Clearly superior: BIG PLUS. The simultaneous taper and face contact of the tool fitting in the BIG PLUS machine spindle ensures an extremely stable connection between the tool fitting and spindle. At the same time, the spindle is compatible with all common SK50 holders.

- Extra-large Z- and Y-axis travel path of 1,000 mm

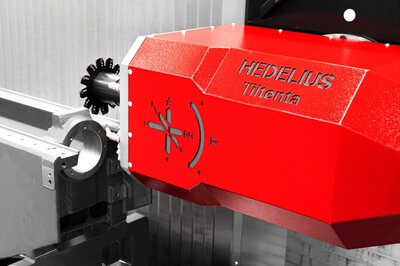

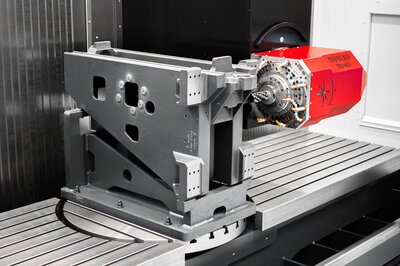

- Infinitely variable swivelling main spindle with hydraulic clamping

- High table load

- oscillating machining

- Motor-activated automatic doors for high ease of use

- Optionally with integrated heavy-duty rotary table

- Highlight: Tool magazine with access to up to 192 tools

- Tool lengths up to 400 mm

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

TILTENTA 10-4600

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 4600 x 1000 x 1000 mm | - | - | |||

| Oscillation mode | ||||||

| Oscillation mode | 2 x 1965 mm | - | - | |||

| Swivelling area | ||||||

| Swivelling area | -5° – +98°/-98° – +98° | - | - | |||

| Output | ||||||

| Output | 50 kW | - | - | |||

| Speed range | ||||||

| Speed range | 8000 / 12000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 50, BT 50, HSK A100 | - | - | |||

| Capacity | ||||||

| Capacity | 40 / 192 | - | - | |||

| Contact surface | ||||||

| Contact surface | 5080 x 1100 mm | - | - | |||

| Fixed machine table max. load | ||||||

| Fixed machine table max. load | 6000 kg | - | - | |||

| Face plate rotary table | ||||||

| Face plate rotary table | Ø 1000 mm | - | - | |||

| Collision area diameter | ||||||

| Collision area diameter | Ø 1450 mm | - | - | |||

| Rotary table max. load | ||||||

| Rotary table max. load | 1600 / 2200 kg | - | - | |||

Gallery of the TILTENTA 10 series

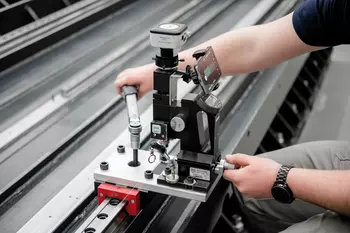

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.