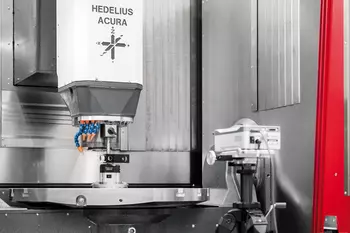

3-axis machining centre FORTE 65 Single 1320 EL

When high cutting performance and precision are required in the smallest of spaces, the FORTE 65 Single 1320 3-axis machining centre is the right choice. The modern Operator's platform design impresses with its high dynamics, regardless of the workpiece weight. With travel paths of 1320 x 650 x 600 mm, the travelling column machining centre offers a surprising amount of space with small installation dimensions. Direct position measuring systems on all axes and the latest generation of drive technology ensure long-term precision.

Your advantages with the FORTE 65

- Generous X travel path of 1320 mm

- Large Z travel path of 600 mm

- Direct measuring systems as standard

- Fully enclosed work area

- Heavy-duty, fixed machine table

- Vertical stainless steel cover for optimised chip fall

- Travelling column made from high-quality machine casting

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

FORTE 65

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 1320 x 650 x 600 mm | - | - | |||

| Oscillation mode | ||||||

| Oscillation mode | - | - | - | |||

| Output | ||||||

| Output | 22 / 29 / 50 / 35 / 30 kW | - | - | |||

| Speed range | ||||||

| Speed range | 14000 / 15000 / 18000 / 22000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 40, BT 40, HSK A63 | - | - | |||

| Capacity | ||||||

| Capacity | 65 / 135 / 180 / 245 / 329 | - | - | |||

| Contact surface | ||||||

| Contact surface | 1500 x 650 mm | - | - | |||

| Fixed machine table max. load | ||||||

| Fixed machine table max. load | 1200/2000 kg | - | - | |||

Gallery of the FORTE 65 Single 1320.

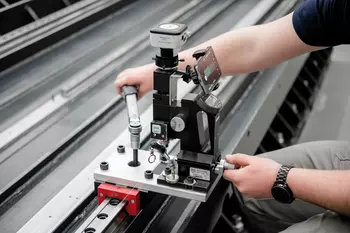

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.