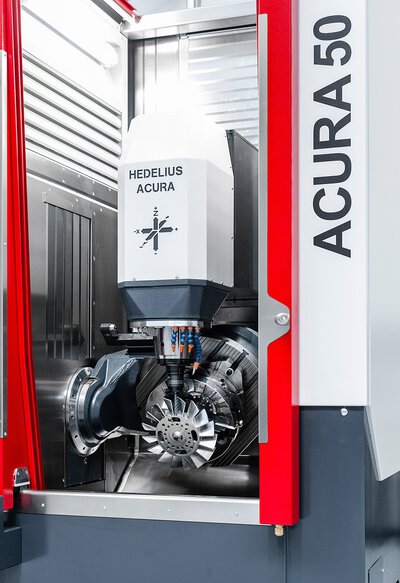

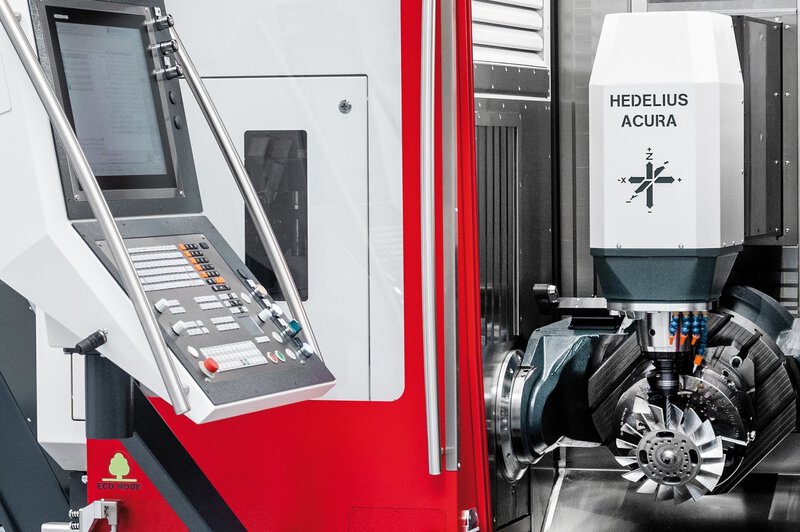

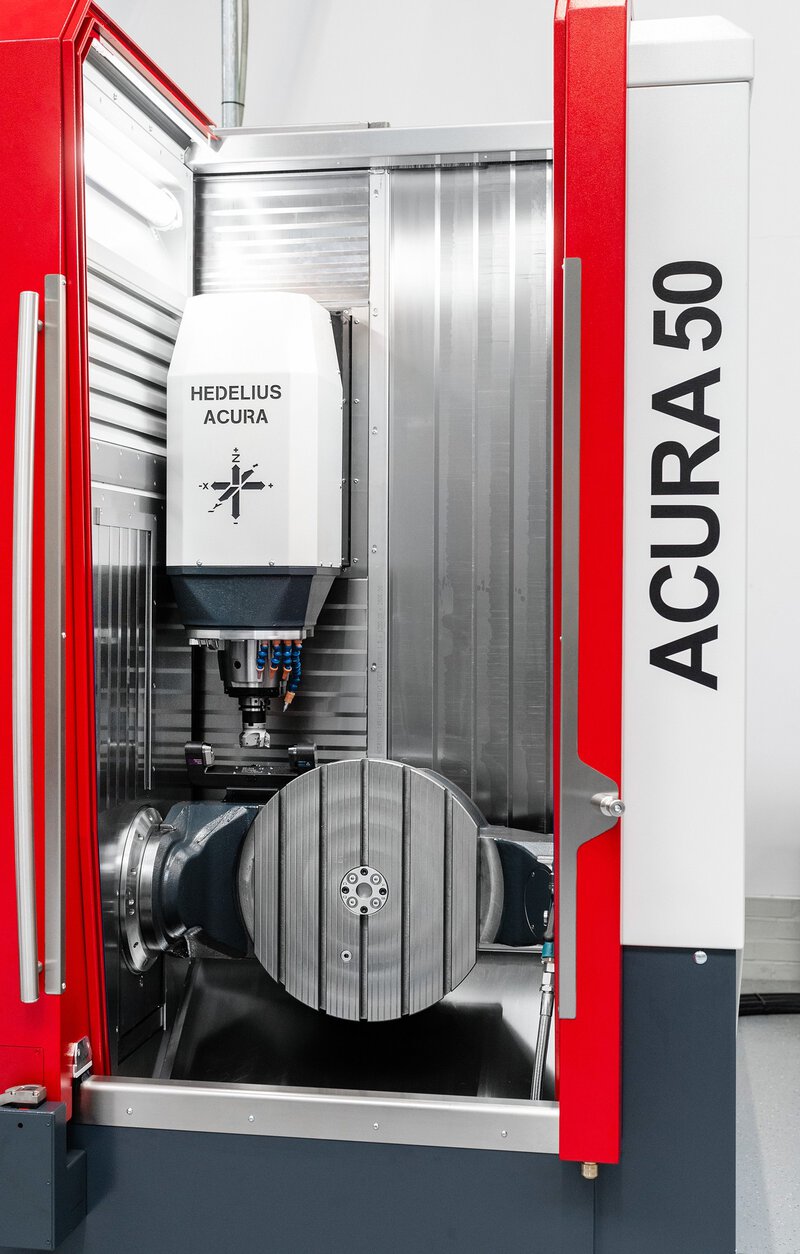

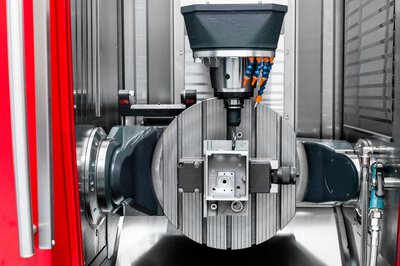

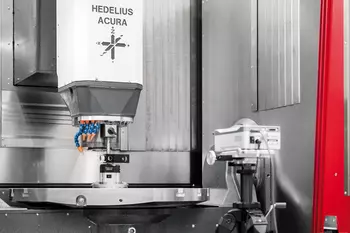

Machining centre with rotating/swivelling table: ACURA 50

The ACURA 50 offers greater precision on a smaller footprint. The constantly guided Y-axis in conjunction with the solidly ribbed feed carriages made of grey cast iron reduce vibrations. The rotating/swivelling table is bearing-mounted on both sides and the Z-axis is specially protected against heat distortion. These and many other details increase the quality of machining, while the dimensions of the 5-axis machining centre are extremely small thanks to the special design.

Your advantages with the ACURA 50

- Z travel path of 550 mm

- Rotating/swivelling table mounted on bearings on both sides for high-precision chipping

- Backlash-free direct drive in the C axis

- 55- or 80-place tool magazine can be operated from the front

- Optimised chip fall thanks to vertical stainless steel cover

- Chip conveyor can be pulled out to the front on rollers to save space

- Low overall height, low installation depth

- 5-axis simultaneous milling optional

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

ACURA 50

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 500 x 550 x 550 mm | - | - | |||

| Swivelling area | ||||||

| Swivelling area | +30° – -115° | - | - | |||

| Output | ||||||

| Output | 22 / 29 / 35 / 30 kW | - | - | |||

| Speed range | ||||||

| Speed range | 14000 / 18000 / 22000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 40, BT 40, HSK A63 | - | - | |||

| Capacity | ||||||

| Capacity | 55 / 80 / 125 / 170 / 235 / 319 | - | - | |||

| Dimensions rotating/swivelling table | ||||||

| Dimensions rotating/swivelling table | Ø 500x430 mm | - | - | |||

| Load rotating/swivelling table max. | ||||||

| Load rotating/swivelling table max. | 300 kg | - | - | |||

| Collision area diameter | ||||||

| Collision area diameter | Ø 550 mm | - | - | |||

Gallery of the ACURA 50.

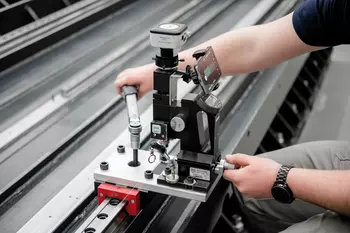

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.