Modern control technology.

CNC control systems from HEIDENHAIN and SIEMENS.

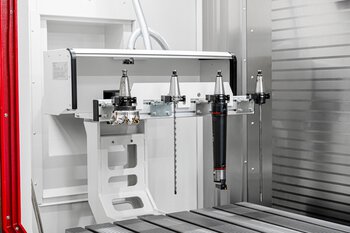

What is usually considered special accessories is standard at HEDELIUS: All machining centres are equipped with a CNC full keyboard, colour monitor, spindle feed overdrive and original software as standard. State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality. You decide which system you want to work with.

HEIDENHAIN TNC7.

The new generation.

The TNC7, the new generation of controls from HEIDENHAIN, combines high-quality hardware components with an advanced, customisable user interface and a generous package of functions. The result: a completely new look and feel for operating a CNC control with which users can work very precisely and intuitively. The TNC7 is 100% compatible with its predecessor, the TNC 640, so that existing NC programs can be transferred and executed without any adaptation effort.

24'' full HD monitor, optimised for workshop use

Very high operating dynamics

Fluid, absolutely delay-free touch operating

Form-based and dialogue-guided user interface

Perfect ease of use of the software thanks to intuitive touch gestures

Optimal orientation: individual arrangement of working ranges, freely rotatable graphics

Graphic contour programming with drawing gestures directly on the touchscreen

Context-sensitive dialogues and help functions

SIEMENS SINUMERIK ONE.

The digitally native CNC.

SINUMERIK ONE - the digital native CNC with the future-oriented CNC system for highly productive machine tools. With its digital twin, the key element for digital transformation, the SINUMERIK ONE helps to simulate and test work processes completely virtually - saving time, resources and costs. This works not only for initial commissioning, but for every programme creation. New programmes can be tested and new machining strategies tried out without risk.

The SINUMERIK ONE draws output from a multi-core processor for short block cycle times, smooth operating with powerful simulation and fast drive control

With the highly integrated Simatic S7-1500, PLC automation tasks are processed much faster both in the machine and on the shop floor

Together with the powerful SINAMICS drives, complex machining tasks are completed efficiently and accurately