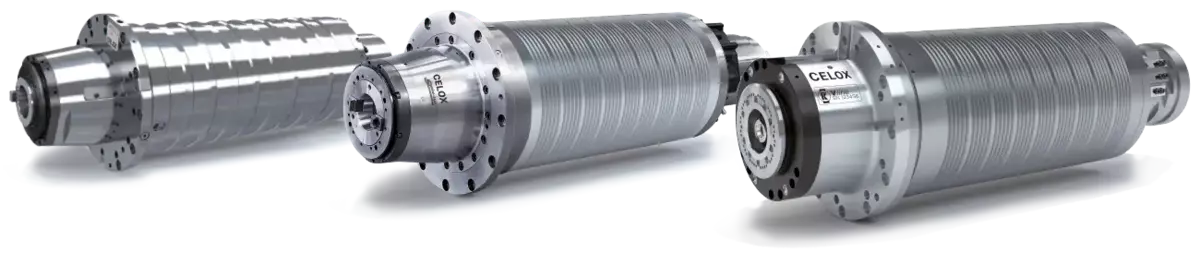

Celox-integral motorised spindles.

Liquid-cooled motor spindles with precision cooler.

High-output and high-torque CELOX integral motor spindles with hybrid bearing technology ensure the technological lead of HEDELIUS machining centres. In conjunction with the HSK interface, the hydromechanical tool clamping system guarantees maximum system rigidity and concentricity.

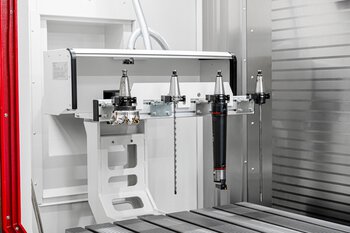

HEDELIUS offers different spindles depending on the application: Customers can choose between powerful spindles with low speeds for heavy-duty machining and spindles with high speeds for machining aluminium or plastics. There is a choice of SK 40, SK 50, HSK A63 or HSK A100 tool fittings.

Tool fitting | Spindle output | Spindle speed |

SK40 / BT40 / HSK A63 SK40 / BT40 SK40 / BT40 SK40 / BT40 / HSK A63 HSK A63 HSK A63 SK50 / BT50 / HSK A100 SK50 / BT50 / HSK A100 | 22 kW / 117 Nm 29 kW / 183 Nm 37 kW / 185 Nm 35 kW / 136 Nm 50 kW / 217 Nm 30 kW / 70 Nm 50 kW / 300 Nm 50 kW / 300 Nm | 14.000 min 14.000 min 14.000 min 18.000 min 15.000 min 22.000 min 8.000 min 12.000 min |