BMO Infinity

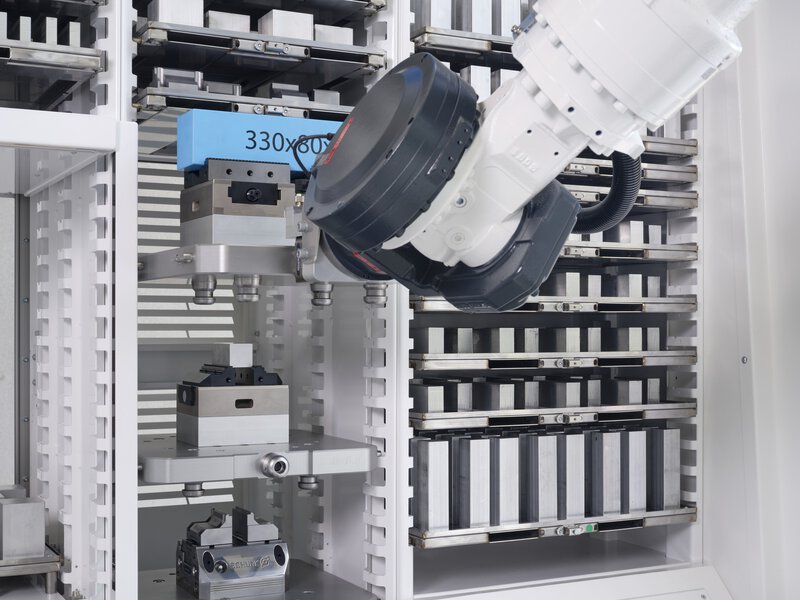

While the number of workpieces that can be processed in the robot cells of the Platinum and Titanium series is limited by the number of drawers, the robot cells of the Infinity series can accommodate an almost unlimited number of workpieces and pallets. This is made possible by flexibly divisible shelves and integrated height control for optimum utilisation of the shelf capacity. The workpieces are stored on grid trays. In order to be able to react very flexibly to small batch sizes, heavy parts or complex clamping situations, the Infinity solution has pallet locations for holding a wide variety of clamping devices. As true multi-batch automation, the robot first automatically inserts the required clamping device into the machine and then tools the device from the trays with the raw parts.

Your advantages with the BMO INFINITY

- Loading one, two or more CNC machines with a robot

- 6-axis robot with a maximum load capacity of 225 kg

- Several product series in one production run

- Many different gripping options

- Almost unlimited capacity

- Refilling of raw parts possible during operation

- Variable product heights thanks to freely divisible shelving system with height control

Get the best out of your production

Greater productivity, higher delivery reliability, relieved employees: there are many good reasons for automation in production.

Maschinenvergleich.

Fügen Sie weitere Maschinen hinzu um Leistungsparameter zu vergleichen.

|

||||||

|

BMO Infinity

|

Add machine

|

Add machine

|

||||

| Storage/retrieval station | ||||||

| Storage/retrieval station | Yes | - | - | |||

| Rotatable storage/retrieval station | ||||||

| Rotatable storage/retrieval station | Yes | - | - | |||

| Pallet handling | ||||||

| Pallet handling | Yes | - | - | |||

| Number of pallets | ||||||

| Number of pallets | individual | - | - | |||

| Pallet dimensions | ||||||

| Pallet dimensions | 395x395 mm | - | - | |||

| Collision area diameter | ||||||

| Collision area diameter | - | - | - | |||

| Transfer weight | ||||||

| Transfer weight | 180/225 kg | - | - | |||

| Manipulace s obrobky | ||||||

| Manipulace s obrobky | Yes | - | - | |||

| Gripper | ||||||

| Gripper | Einfach/Doppelt | - | - | |||

| Workpiece dimensions | ||||||

| Workpiece dimensions | 330x80 mm | - | - | |||

| Workpiece storage | ||||||

| Workpiece storage | Shelving system | - | - | |||

| Multi-machine operation | ||||||

| Multi-machine operation | Yes | - | - | |||