Reference reports from HEDELIUS customers.

Over 3000 well-known customers from all over Europe put their trust in the quality and reliability of our machining centres. In our reference reports, you can find out how companies from a wide range of industries have been able to increase their productivity, minimise downtimes and ensure long-term success with solutions from HEDELIUS. Be inspired by the success stories of our customers and discover how your operation can benefit from our advanced CNC technology.

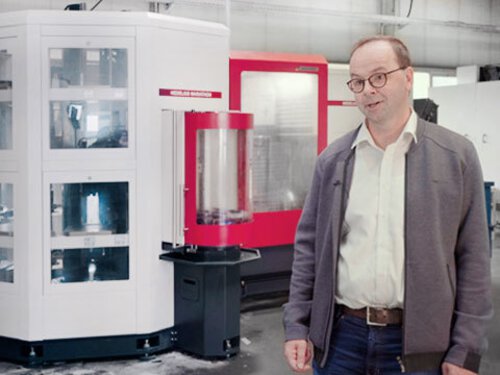

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

Founded as a supplier to the textile industry, MEM Maschinenbau GmbH from Ahaus is now closed in special machinery, systems and steel construction. With the purchase of an ACURA 65 MARATHON in 2021, the operation led by Managing Director Hans-Jürgen Marx took the plunge into production automation - and it is paying off today.

The town of Georgsmarienhütte is named after the local steel company, which grew out of the local mining industry. Today, mining vehicles, special machinery and medical technology are manufactured in one of the former industrial halls of Georgsmarienhütte. Here and at another site, Wendt Maschinenbau GmbH und Co. KG manufactures a broad range of parts, machines, steel structures and devices on behalf of customers.

Since its foundation in 1986, D+P, Dosier- und Prüftechnik GmbH has been developing and producing highly complex standard products and customised systems for applying and dispensing liquids, greases and pastes as well as for assembling components and testing functions. The products of the 60-strong company are mainly used in the automotive and electrical industries as well as in mechanical engineering, assembly technology and the air and space industry.