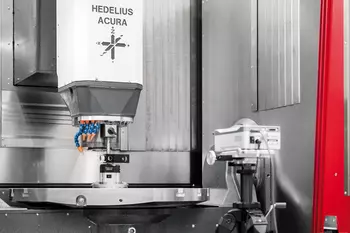

Machining centre with rotating/swivelling table: ACURA 65 MARATHON

The ACURA 65 MARATHON comes with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS MARATHON pallet magazine systems in the series. The ACURA 65 MARATHON remains accessible from the front, even with automation, and the view from the Loading station to the work area is unobstructed. The machining centre has a 65-place tool magazine as standard. As an option, a MAGNUM magazine provides a further 25 tools and a standby magazine provides a further 264 tools.

Your advantages with the ACURA 65 MARATHON

- Automation with HEDELIUS pallet handling systems from the MARATHON series

- Loading from the left side of the machine

- Prepared interface

- Side loading opening with opening height of approx. 900 mm

- Zero point clamping elements Schunk Vero NSA Plus installed at the factory

- Consistent Heidenhain operating concept

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

|

||||||

|

ACURA 65 MARATHON

|

Add machine

|

Add machine

|

||||

| Travel paths (X/Y/Z) | ||||||

| Travel paths (X/Y/Z) | 700 x 650 x 600 mm | - | - | |||

| Swivelling area | ||||||

| Swivelling area | +30° – -115° | - | - | |||

| Output | ||||||

| Output | 22 / 29 / 50 / 35 / 30 kW | - | - | |||

| Speed range | ||||||

| Speed range | 14000 / 15000 / 18000 / 22000 min-1 | - | - | |||

| Tool fitting | ||||||

| Tool fitting | SK 40, BT 40, HSK A63 | - | - | |||

| Capacity | ||||||

| Capacity | 65 / 90 / 135 / 180 / 245 / 329 | - | - | |||

| Dimensions rotating/swivelling table | ||||||

| Dimensions rotating/swivelling table | Ø 400x400 mm | - | - | |||

| Load rotating/swivelling table max. | ||||||

| Load rotating/swivelling table max. | 500 kg | - | - | |||

| Collision area diameter | ||||||

| Collision area diameter | Ø 700 mm | - | - | |||

Gallery.

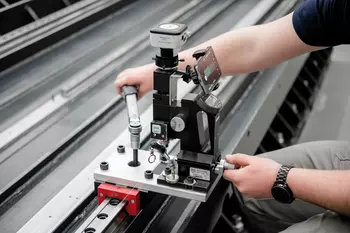

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.