08/08/2023

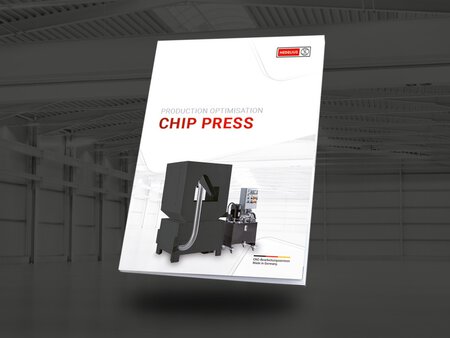

Manufacturing optimisation: chip press.

Turn waste into recyclable materials.

The chipping process produces a not inconsiderable volume of chips. By using a chip press directly at the machining centre, you can produce profitable recyclable materials from residual materials that need to be disposed of. This is because the chip press separates the chips from the cooling lubricants and closes them into clean, handy briquettes. This reduces logistics costs, saves valuable resources, generates additional revenue and protects the environment

Advantages of the chip press.

Economic advantage through clear benefits.

Request product flyer.

Request our product flyer on the chip press free of charge (PDF | EN).

Please fill out the following contact form.

This form requires your consent to third-party cookies. Privacy settings

Further informationMore downloads.

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

(PDF | EN) The 5-axis machining centres in the ACURA series combine compact design with maximum performance and automation readiness ex factory. Whether single parts or series components up to Ø 900 mm and 1,000 kg are machined with high precision. With innovative technology, generous tool capacity and ergonomic design, ACURA machining centres are perfect for demanding production environments. Download the folder now and discover the full potential of the ACURA!

(PDF | EN) The TILTENTA series, a true universal machining centre. Thanks to its long travel paths and high load capacity, even large and heavy workpieces can be machined. The numerous clamping options are particularly ideal for companies with a large variety of parts. Find out more in the series folder.