04.04.2024

Automation

for everyone

Increase efficiency and reduce costs with flexible solutions.

Your production process is as individual as your company itself. That's why we offer you a wide range of automation solutions: From precise pallet and workpiece handling to hybrid solutions and advanced linear interlinking systems. You can rely on tried-and-tested HEDELIUS automation solutions from the MARATHON series or proven technologies from leading third-party providers. Our many years of experience in the automation of CNC machining centres make us a trustworthy partner for your individual project. We are at your side to successfully close your path to automation.

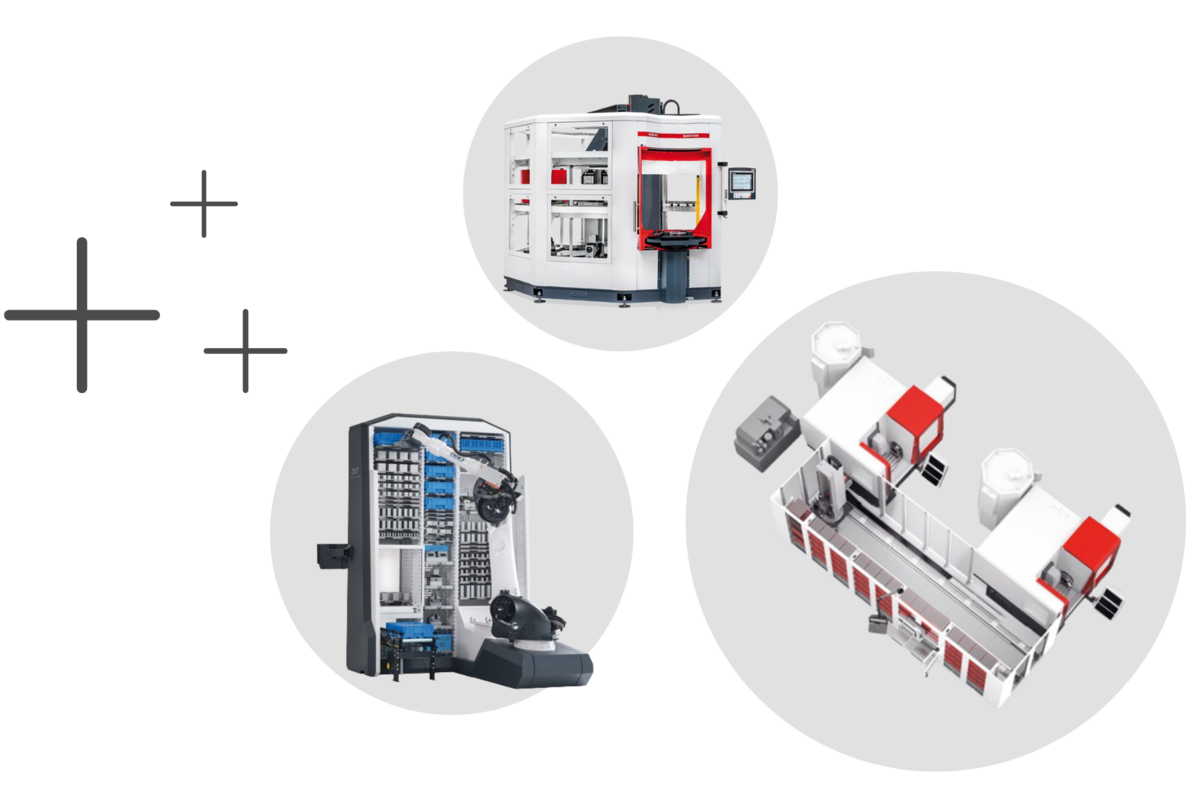

Robotics for beginners

A reliable partner and a user-friendly solution are essential for an uncomplicated entry into automated CNC machining. In cooperation with our partner RoboJob, we offer you a simple and effective complete solution consisting of a five-axis CNC machining centre and robot automation;

ACURA 50 + ROBOJOB Mill-Assist.

This beginner-friendly automation was specially developed for tooling and unloading small series and/or small workpieces. The automation has a 6-axis robot with a load capacity of 25 kg, which picks the workpieces from a fixed table and places them in the ACURA 50 5-axis machining centre. Depending on the available space, the ROBOJOB Mill-Assist can load the machine from the front or from the side.

Nearly unlimited capacity

One of our proven partners for the automation of CNC machining centres is BMO Automation BV from the Netherlands. Their latest automation solution, the BMO Infinity, gives customers maximum flexibility when expanding their workpiece storage.

BMO Infinity for ACURA and TILTENTA.

The robot cells in the Infinity series can accommodate an almost unlimited number of workpieces and pallets. This is made possible by flexibly divisible shelves and integrated height control for optimum utilisation of the shelf capacity. The workpieces are stored on grid trays. In order to be able to react very flexibly to small batch sizes, heavy parts or complex clamping situations, the Infinity solution has pallet locations for holding a wide variety of clamping devices. As a true multi-batch automation system, the robot first automatically inserts the required clamping device into the machine and then tools the device from the trays with the raw parts.

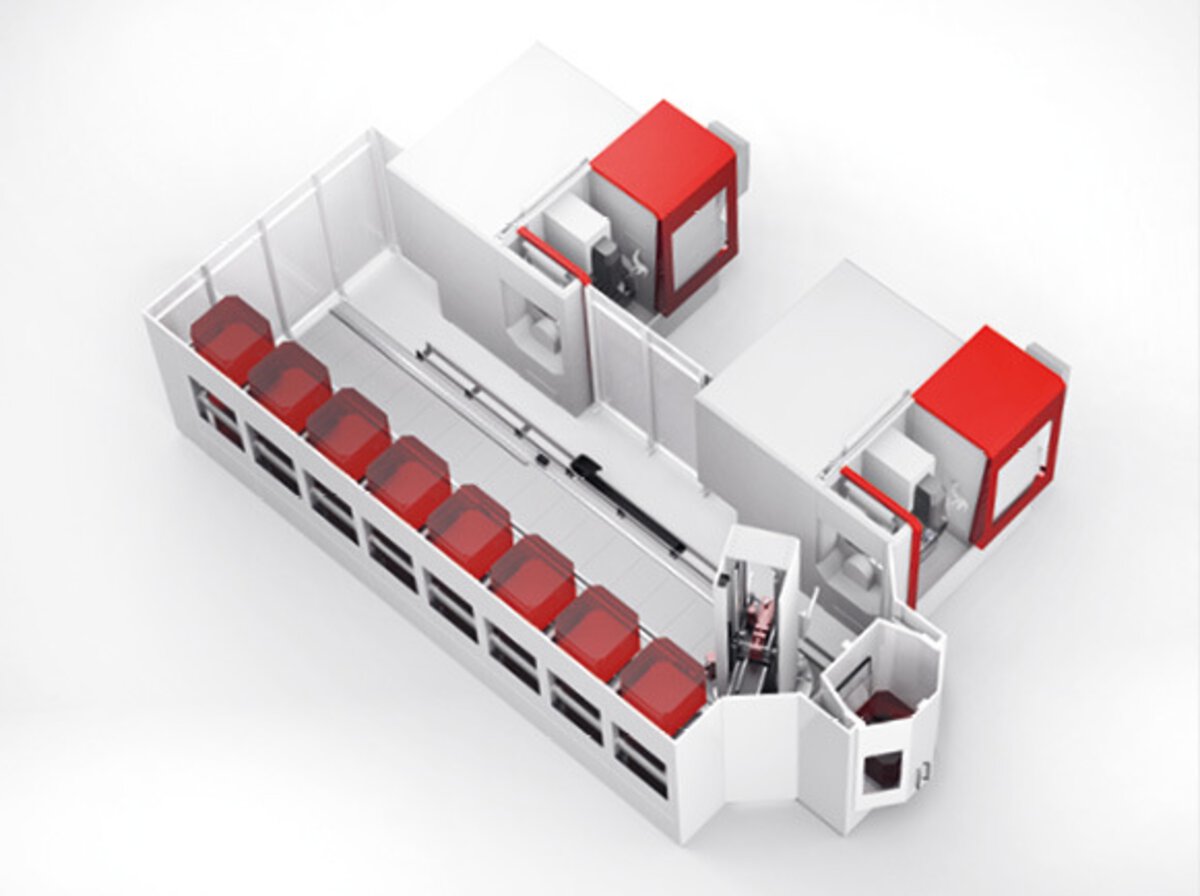

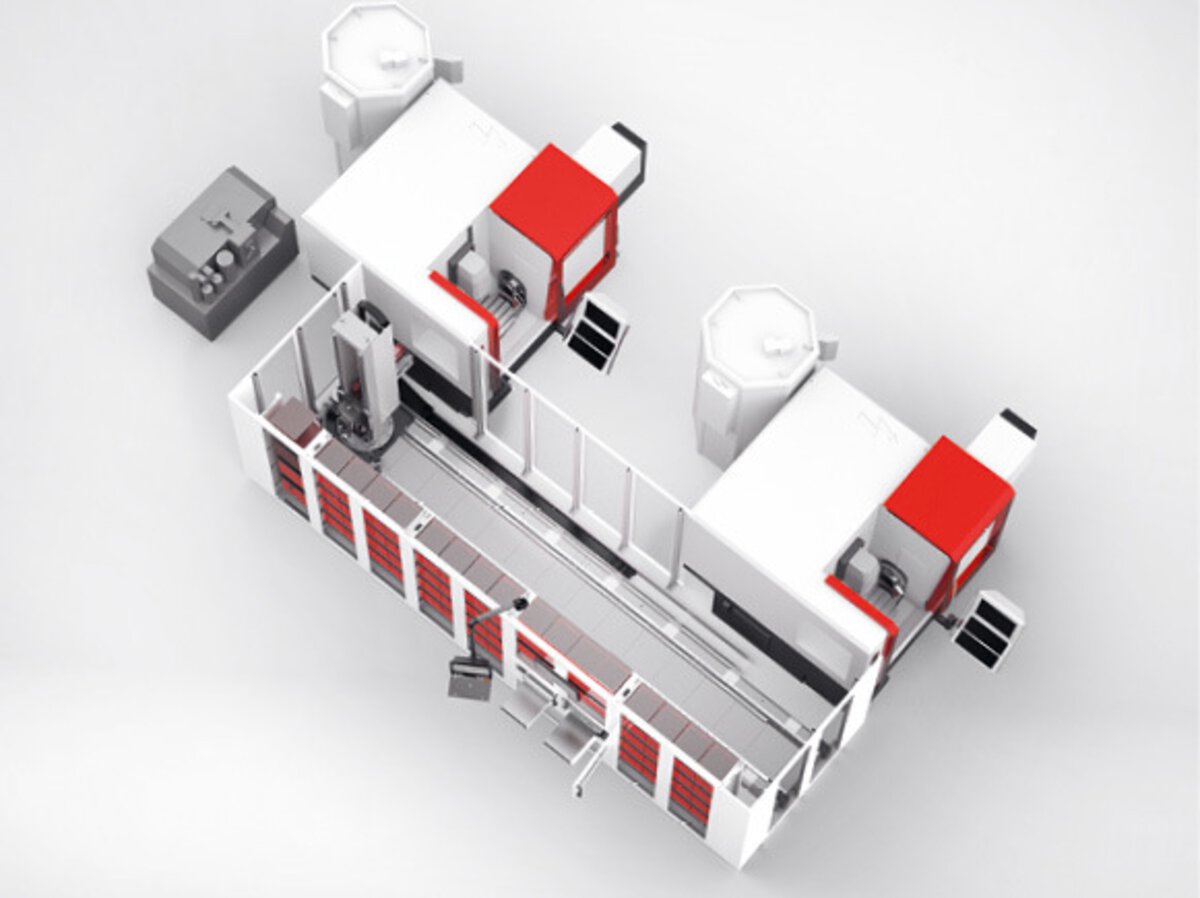

Scalable production cells

In order to optimally convert the available space into productivity, the trend is towards large pallet magazines and the networking of several machining centres. This allows different orders to be processed in parallel and lead times to be drastically reduced.

2 x ACURA 65 + Indumatik 200.

With a total of 76 pallet locations of 320 x 320 mm or 58 pallet locations of 400 x 400 mm with a transfer weight of 200 kg, this configuration from Indunorm ensures the efficient production of a wide range of workpieces. The two storage/retrieval stations are flexible in their arrangement and offer optimum adjustment to the spatial conditions. The integration of the job manager software for order management and prioritisation optimises the overall performance of the system.

2 x ACURA 85 + Indumatik 500.

With a total of 24 pallet locations measuring 500 x 500 mm with a transfer weight of 500 kg, the Indumatik 500 is the perfect solution for our ACURA 85 high-performance machining centres. The rotatable loading station is flexible in its arrangement and can be positioned according to spatial requirements. The integration of the job manager software for job management and prioritisation optimises the overall performance of the system.

Your automation partner

Over the past few years, we have developed from a manufacturer of CNC machining centres to a competent full-service provider for CNC solutions. Our extensive expertise is reflected in numerous automation projects that we have realised in close cooperation with our customers.

Counselling interview

Our experts will be happy to support you with advice and implementation of your customised solution concept. Arrange a free consultation now and discover together with us what potential various automation solutions hold for your production.

This form requires your consent to third-party cookies. Privacy settings

Further informationMore news

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!