18 November 2020

HEDELIUS SHOCKS INTO NEW DIMENSIONS.

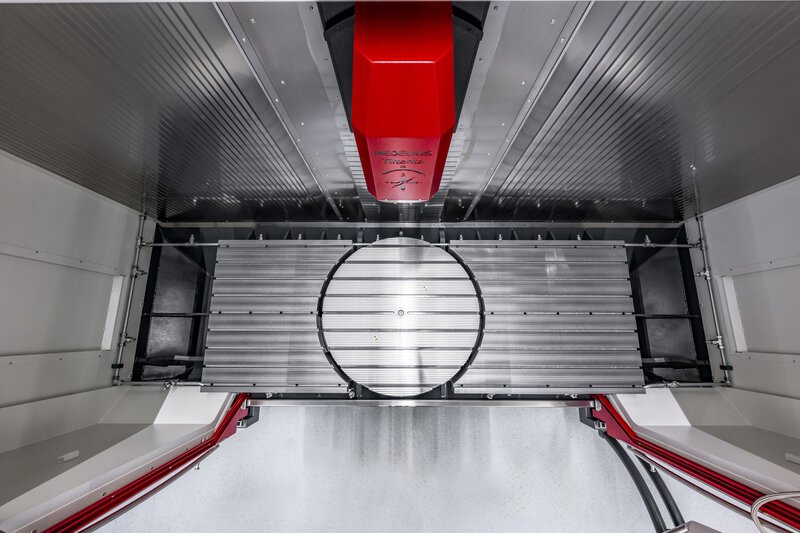

TILTENTA 11 is about to enter the market.

The TILTENTA series, which can be used flexibly and is very popular with customers, has a new addition - and it's not exactly small. With a considerable Y travel path of 1,100 mm, the new TILTENTA 11 impresses with a very large work area in which even solid components can be machined with 4/5 axes. The swivelling head milling machine is available on the market in three variants, namely as the T11-2600 with an X travel path of 2,600 mm in accordance with this, as well as the T11-3600 with an even larger X travel path of 3,600 mm and the T11-4600 with an X travel path of 4,600 mm.

With integrated NC rotary table, 5-side complete processing possible

The versatile 4-axis machining centre with infinitely variable swivelling main spindle can be upgraded to a 5-axis machining centre through the optional use of a heavy-duty rotary table integrated at the same level, making it even more flexible in production. With a maximum table load of 6,000 kg on the fixed machine table and 1,800 kg on the rotary table, the production of massive large workpieces is no problem. The contact surface of the machine table is 3080 x 1100 mm for the TILTENTA 11-2600, 4080 x 1100 mm for the TILTENTA 11-3600 and 5080 x 1100 mm for the TILTENTA 11-4600.

Large travel paths, large tool magazine

Not only the work area, but above all the travel paths are impressive: At 2600 x 1100 x 900 mm (x/y/z), the TILTENTA 11-2600 is ideally suited for large welded constructions or base plates, but smaller components can also be clamped several at a time. The TILTENTA 11-3600 and 11-4600 provide significantly more work area in the X-axis. The machining centres have 65 tool positions as standard and can also be equipped with an additional 180 tools to open a total of 245 tools using a standby magazine.

50 kW spindle for heavy-duty machining

The milling machine from the HEDELIUS swivelling head family offers a wide range of spindle options. You can choose between SK 40 and HSK A63 tool fittings and spindle speeds of 14,000, 15,000 and 18,000 rpm. In terms of spindle output, you can choose between 22, 29, 35 and 50 kW, which means that the TILTENTA 11 is also well installed for heavy-duty machining.

Very high flexibility

With the combination of a large contact surface and high clamping weights, large travel paths and a generous work area, a precise swivelling spindle and a built-in rotary table as well as the large tool magazine, the TILTENTA 11 enables enormous flexibility in production. The swivelling head machining centre helps to ensure that customer orders can be processed faster and more precisely and that tooling times and costs are significantly reduced.

The TILTENTA 11 series.

More news.

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!

(PDF | EN) The 5-axis machining centres in the ACURA series combine compact design with maximum performance and automation readiness ex factory. Whether single parts or series components up to Ø 900 mm and 1,000 kg are machined with high precision. With innovative technology, generous tool capacity and ergonomic design, ACURA machining centres are perfect for demanding production environments. Download the folder now and discover the full potential of the ACURA!