01.06.2024

Beginner-friendly robot automation

RoboJob Mill-Assist at the HEDELIUS technology centre

Discover our latest highlight at the HEDELIUS technology centre: the RoboJob Mill-Assist robot automation system. In conjunction with the ACURA 50 EL, this solution offers intuitive and efficient processing of small series and workpieces.

Find out more about the advantages of this automation system and how it can increase efficiency, capacity and flexibility.

We would also be happy to present this automation concept to you live.

We look forward to welcoming you to our HEDELIUS technology centre!

Technical highlights

Connected to the left-hand side of the machine, the Mill-Assist loads the machining centre through a loading opening. Thanks to the side loading, the work area remains fully available for set-up and control work, but also, for example, for single part production during the day shift. Even crane loading of the machine is possible without restrictions.

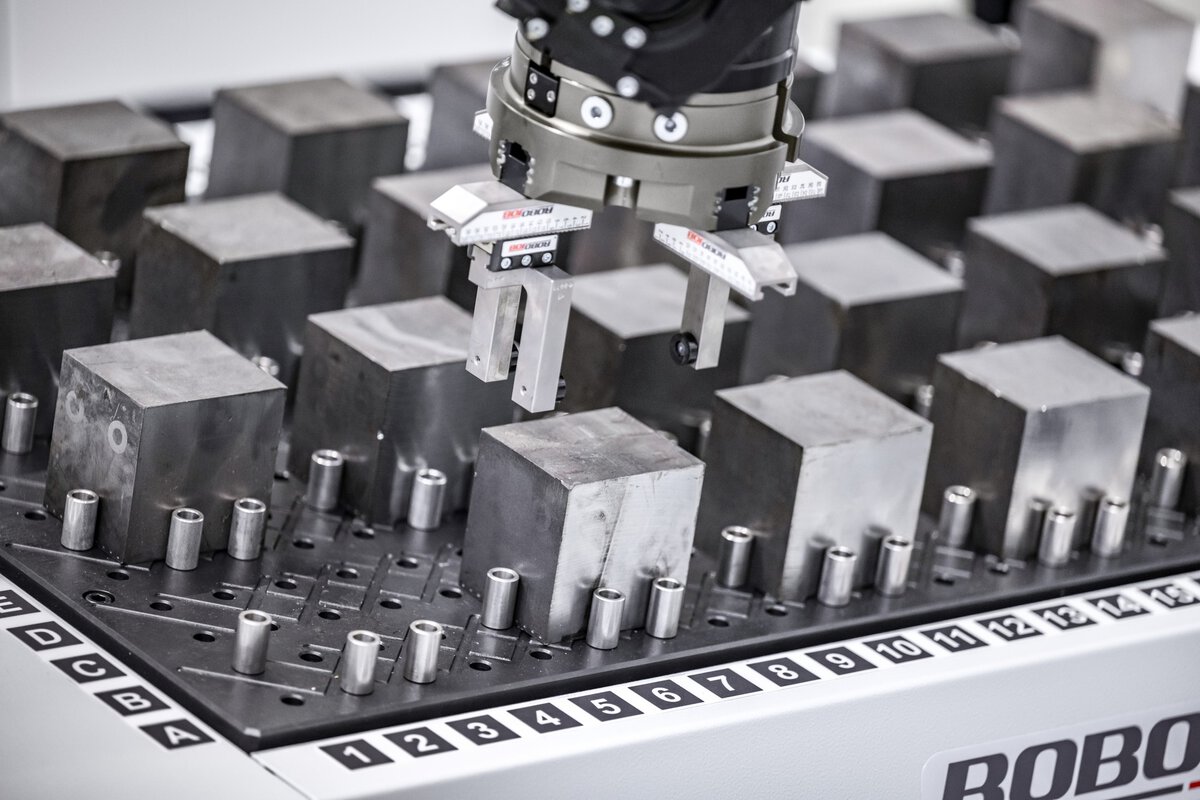

6-axis robot with 25 kg load capacity

The robot arm of the Mill-Assist has a maximum transfer weight of 25 kg. The double gripper, for gripping raw and finished parts, takes the parts from the grid support and places them in the clamping device on the work table of the ACURA 50 EL. The length of the workpieces must be between 20 and 250 mm.

Graphical user interface for easy retooling

The operating panel allows the user intuitive graphical operating even without robot knowledge. Other aspects such as the clear 3D visualisations in the software and a set-up time for new workpieces of around 5 minutes round off the user-friendly operating concept. The software can also be easily supplemented with user-defined, specific optional features.

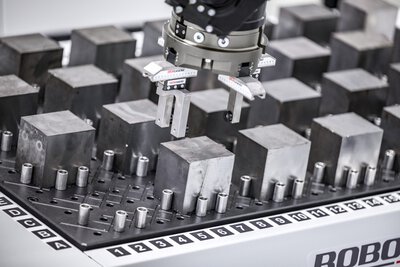

Highest capacity in the smallest space

RoboJob's patented stacking principle offers maximum capacity in the smallest of spaces. Workpieces can be stacked at a height of up to 350 mm. Grid plates are not absolutely necessary, but can be integrated if the customer so wishes. Based on this principle, a wide range of Workpiece dimensions can be loaded by the Mill-Assist.

Maximum flexibility thanks to innovative gripping system

The flexibility of the gripping system allows the user to automate a wide range of workpieces. The infeed and outfeed of the workpieces can be individually configured. A compressed air nozzle integrated into the gripper also ensures that the clamping system is cleaned before each workpiece change. The concept is rounded off by a quick and uncomplicated process for changing the grippers.

User video

Watch the video below for a brief insight into the user-friendly operating of the RoboJob Mill Assist. The changeover process on the ACURA 50, from single parts to series production, takes place in just a few simple handles.

This video requires your consent to third-party cookies. Privacy settings

Further informationGallery

Arrange a demonstration appointment

Experience live

See the performance of the combination of ACURA 50 EL and RoboJob Mill-Assist for yourself and arrange a personal demonstration appointment now. You can also discover many other CNC machining centres and automation solutions that our technology centre has to offer. We look forward to seeing you here in Meppen!

More news

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!