SD Automotive GmbH | ACURA 65, TILTENTA 7-2600

Field of application: Automotive | Company headquarters: Georgsmarienhütte, Germany | Employees: 430

Within just a few years, SD Automotive GmbH has developed into a specialised service provider for the automotive industry. By constantly expanding its machinery, the company has been able to meet the high demands placed on milling in particular. The latest technology in the chipping range comes from HEDELIUS in Meppen.

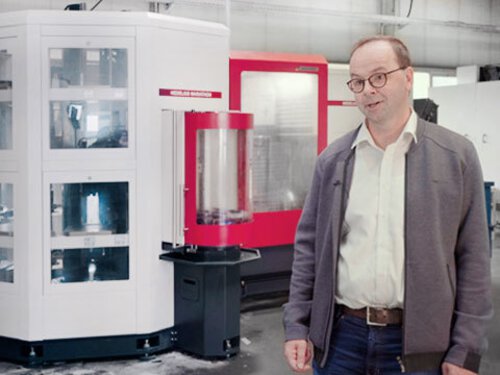

"Three quarters of the added value of an automobile is created by suppliers and service providers. SD Automotive GmbH, founded in 1984, is one such service provider. The expertise of the company from Georgsmarienhütte in Lower Saxony ranges from tool and prototype construction to model and body construction and the production of Spare parts. In its almost 35-year history, the medium-sized company with 430 employees has become one of the leading providers in this range. Customers, including many of the well-known international automotive manufacturers and their suppliers, are extremely demanding. "We often receive precisely defined specifications from our customers, including prescribed materials," explains Ulrik Standfuß, responsible for operational management at SD Automotive GmbH. To ensure that the requirements can be met, much is done in-house, from engineering to the finished part. But the family-owned company's suppliers also have to fulfil high standards. "The quality of the purchased materials must be very good and we also set the highest standards for further processing in order to meet the requirements of our customers," explains Ulrik Standfuß. This is why the company regularly invests in modern machine technology. Most recently in four machining centres from HEDELIUS.

More delivery with higher speed and precision.

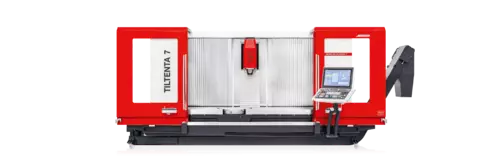

Older CNC milling machines were to be replaced in order to close the quality and productivity gap in production. Those responsible at SD Automotive spent a year looking at, evaluating and testing machines. The decision was then made to open two ACURA 65 and two TILTENTA 7-2600 5-axis machining centres from the North German machine manufacturer HEDELIUS. The high stability of the milling machines was particularly convincing. "With the HEDELIUS machines, we can feed more and therefore remove more material and still achieve a high speed and the required precision. We tested many other manufacturers where this was not possible," says Bardhyl Beqrama about the selection process. As head of the chipping department, he knows what is important when it comes to machining centres. He is responsible for a machine park of a good 20 CNC machines and has already been involved in several investment decisions. In addition to stability, other factors were also important in determining the result. "Of course, the precision had to be right, so we also carried out test machining on site in Meppen. The parts also needed to be machined in a single clamping operation, which is possible with the HEDELIUS machines. What's more, the machining centres are very compact. They fit perfectly into our hall," he explains. The complete enclosure with simultaneous crane loading option, the large monitor of the HEIDENHAIN control system and the large window of the tool magazine on the ACURA 65, which can be operated from the front, and the sliding terminal on the TILTENTA 7-2600 were also impressive. In order to become even more productive and reduce tooling times, all machines were equipped with a zero-point clamping system. "With the zero-point clamping system, we can always leave the vices open on a plate and then only have to insert them into the clamping system. This significantly reduces our tooling times," says Bardhyl Beqrama, convinced by the system.

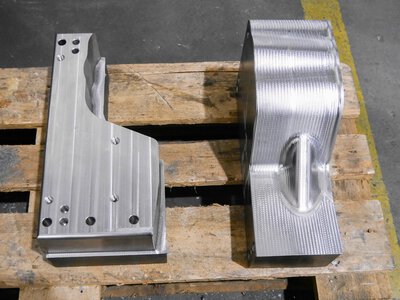

Small spacers and large tool elements.

The two ACURA 65 machines, with travel paths of 700 x 650 x 600 mm (x/y/z) and rotating/swivelling table, are used to produce mould segments and cutting elements, among other things. The two T7-2600 machines with swivelling head are used even more flexibly. The large contact surface and the high table load make it possible to machine mould parts up to 1400 mm in length and up to 300 kg in weight. Bardhyl Beqrama explains: "We are not yet fully utilising the length of the machines. At the moment, we are producing everything from small spacers to 1.4 metre tool elements on the machines. However, it is important for us to have the flexibility. The market is changing and we have to be prepared for that." With travel paths of 2600 x 750 x 695 mm (x/y/z) and a clamping weight of 2500 kg, there is definitely still plenty of air for the future.

All-round satisfaction with man and machine.

The flexibility argument becomes even more important when batch sizes are considered. "There are very few repetitions for our products; we almost exclusively manufacture one-offs. The lead times for workpieces are between five minutes and several hours," says the department head, describing the production situation. He goes on to explain: "We machine various materials from steel and tool steel to cast iron, aluminium and plastics, even if the latter is only rarely the case."

SD Automotive GmbH has been working with the four HEDELIUS machining centres since spring 2017. Following the purchase, the automotive supplier is also satisfied with the services. "We only had a centimetre of space between the gate and the T7 during the installation, but the installation was very professional and worked perfectly. The commissioning afterwards was also super fast," says Bardhyl Beqrama. And Ulrik Standfuß adds: "We are very satisfied with these machines. So far there have been no breakdowns and no problems, despite working in two shifts. There is also nothing to criticise about the service from HEDELIUS."

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.