Edumar Metaalbewerking BV | ACURA 65 EL

Field of application: Contract manufacturing | Company headquarters: Someren, Netherlands | Employees: 32

At Edumar Metaalbewerking in Someren, the Netherlands, spindle hours count and production is planned to be highly efficient. Many of the metalworking company's turning and milling machines are therefore equipped with automation solutions. At the beginning of the year, an ACURA 65 EL from HEDELIUS was put into operation with a Titanium 180 from BMO Automation. In combination with the automation system, the 5-axis machining centre is expected to achieve up to 8,000 spindle hours per year.

Brothers Marius and Eduard Wijlaars founded Edumar Metaalbewerking in Someren, the Netherlands, in 1995. It all started in a barn after work and at weekends. "We worked at our jobs during the day and worked in our own company in the evenings and at weekends. At some point, we only worked in our company," recalls Marius Wijlaars. 23 years after the company was founded, Edumar now employs 32 people, half of whom were trained by the company itself. The company has also long since moved from the agricultural building to a state-of-the-art production hall. However, the old location has not been completely abandoned: "Since 2017, we have been in our 1,800 m² hall on Broekstraat in Someren, where the mechanical production is located. We have expanded the old site several times over the past few years and there is still an assembly department there today," explains Managing Director Marius Wijlaars.

Through and through efficient production.

The metalworking specialist from Someren mainly manufactures stainless steel and aluminium components for Dutch and German customers in the packaging and medical technology, food and chip industries as well as for shipbuilding and toolmaking. The company also produces for contract customers in bearing in order to keep production flexible and fully utilised on the one hand and to guarantee short delivery times for customers on the other. "Thanks to our automated production and stockpiling of components, we can now deliver within a very short time. This is despite the fact that we often produce prototypes or small series of a maximum of 50-100 parts," reports owner Marius Wijlaars proudly. And the mechanical production on Broekstraat is impressive. Seven lathes and nine milling machines, often paired with automation systems, are located close together. Everything is thoroughly organised, structured and trimmed for efficiency. Marius Wijlaars explains: "Before we started with automation, we were able to produce one part per night, then seven parts with the first automation systems, and later 16. Today we are much further ahead. The machines are all networked so that drawings and end programs can be accessed on every machine." In the future, Edumar would like to take a further step. The machines should then communicate with each other independently and report when problems occur, lubricants run out or other restrictions threaten productivity.

Great confidence in ACURA 65 EL.

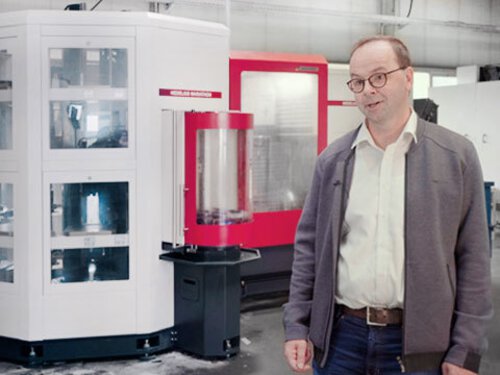

So it's no wonder that high demands are also placed on the output of the machines. Each new machine is designed to be even more productive. The most recent purchase was an ACURA 65 EL from HEDELIUS Maschinenfabrik GmbH in Meppen. "The last machines we purchased were open for 5,000 or 6,000 spindle hours. With the HEDELIUS, we want to achieve up to 8,000 spindle hours per year. We have nothing to gain from standstill," says Eduard Wijlaars, defining the ambitious goal. That is a capacity utilisation of over 90 %. This also places a great deal of trust in the ACURA 65 EL and the automation from BMO Automation. The automation manufacturer is already represented at Edumar with various systems and is therefore no stranger to the company. This is the first machining centre from the North German manufacturer HEDELIUS. "We knew from acquaintances that HEDELIUS is good and that the price/performance ratio is right. We looked at an ACURA 65 for the first time at Promas and then travelled to the HEDELIUS factory. There we were convinced by the machine," says Eduard Wijlaars. Promas BV - Professional Machine Support is the Dutch trading partner of HEDELIUS and is also responsible for service in the Netherlands.

Precision at the nanoscale.

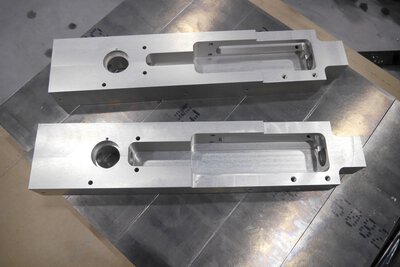

Various factors were ultimately decisive for the purchase of the ACURA 65 EL, such as the rotating/swivelling table, the user-friendliness and the accessibility of the machine from the front, despite automation. "Thanks to the side robot loading of the ACURA, we can still set up single parts in the machine from the front during the day shift and the work area remains fully accessible," says Marius Wijlaars, describing the advantage. The compact machine also impresses with its precision. Edumar Metaalbewerking manufactures components for materials analysers, for example, and these have to meet the highest quality standards. There must not even be any scratches on the components and everything must be documented in a measurement protocol. Other parts for adhesive devices must be within a tolerance range of one to 1.5 hundredths over the entire machined length, and internal fits must even be in the nanometre range. The component size on the ACURA 65 EL starts with small parts measuring 50 x 50 x 80 mm and is only limited at the top by the machine's travel paths of 700 x 650 x 600 mm (x/y/z).

Convincing tool magazine.

Another convincing argument in favour of the ACURA 65 EL was the integrated 65-position tool magazine and the additional standby magazine with 180 tools and a cone cleaning station. This means that the tools required for machining operations are always available in the magazine, including the sister tools. This prevents machine breakdown in the event of tool wear or tool breakage. "The large tool magazine is formidable," says Marius Wijlaars enthusiastically. "We have no tool set-up times." Thanks to the cone cleaning station, the tools can remain in the standby magazine, eliminating the need for regular removal, cleaning and reinsertion and thus almost completely reducing a high cost factor. If a tool is not available for a component, the robot automatically stops the workpiece and selects another one where the tool is not used. This means that production can continue without interruption.

There is contentment.

The ACURA 65 EL from HEDELIUS has been in operation with the Titanium 180 from BMO Automation since the beginning of 2018. As all employees already have experience in working with 5-axis machines and HEIDENHAIN control systems, no additional training was necessary. The system could be used immediately. "We have very experienced, committed and reliable people who immediately familiarised themselves with the machine," says a satisfied Eduard Wijlaars. And the interaction between the ACURA 65 EL and the Ti180 also works very well. Managing Director Wijlaars: "We are very satisfied with the system, the machine and automation work well together." Edumar Metaalbewerking in Someren has no regrets about purchasing the first HEDELIUS.

HEDELIUS machining centres of the customer.

More testimonials.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.