Fraune Metallbearbeitung GmbH & Co. KG | ACURA 65 MARATHON with MARATHON SR422

Field of application: Mechanical engineering, air and aerospace, medical technology and motorsport

Company headquarters: Delbrück, Germany | Employees: 8

Productivity leap through automation:

Fraune trusts in HEDELIUS

Highest precision, modern production technologies and partnership-based cooperation with customers from demanding industries - Fraune Metallbearbeitung GmbH & Co KG from Delbrück in East Westphalia is committed to this promise of quality. In 2022, the family business led by Managing Director Heinrich Fraune took the first step towards automated production - with the compact ACURA 65 5-axis machining centre and the MARATHON SR422 multi-pallet storage system from HEDELIUS.

Broad range of services, high vertical integration

The company's production portfolio covers the full range of machining: 5-axis and 3D milling, CNC turning, welded assemblies, laser cutting and CAD-supported development and design are just as much a part of day-to-day business as feasibility analyses and the manufacture of ready-to-install components. Thanks to this high level of vertical integration, Fraune offers its customers "metalworking from a single source" - a decisive advantage, especially for complex or time-critical projects.

Like father, like son

It all began in 1991, when Martin Fraune founded the company as a sideline. He quickly made a name for himself in the industry with conventional turning and milling technology, grinding technology and the manufacture of stamped parts.

The increasing demand - including for customised solutions for medical and food technology - soon enabled him to steadily expand his machinery. The first CNC machines were also purchased at the end of the 1990s.

His son Heinrich also felt right at home where the chips were flying. "Even as a child, I spent a lot of time in production. I was always allowed to watch and help out a little - it was pure fascination," he recalls his father's early influence. So it was a mere formality that he wanted to follow in his father's footsteps and learnt to be a cutting machine operator. Since 2012, the now 36-year-old has been running the eight-strong family business in the second generation. He still enjoys being at the machine himself, even if the day-to-day business rarely leaves him time for it. After all, the order situation is very good, he reports.

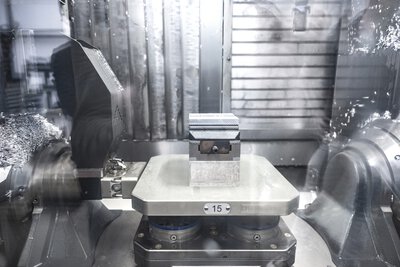

The Fraune company's customers come from demanding industries. With the pallet shown, operators can recalibrate the machine kinematically in fully automated pallet operation to ensure consistently high precision.

Reliable precision for highly specialised industries.

The family-owned company's customers come from technology-driven, demanding industries. The company primarily supplies companies from the mechanical engineering, air and aerospace, medical technology and motorsport sectors. All projects are united by their need for high-precision components that require documentation. Over the years, Fraune has built up an excellent reputation in this range as a reliable and flexible service provider, underpinned by its ISO 9001 certification, short response times and personalised technical advice at eye level.

"I wanted to have them back then"

In the course of the generational change, Fraune also became increasingly aware of HEDELIUS again. "I was invited to Meppen in 2012 and saw the latest 5-axis technology from HEDELIUS there for the first time. I wanted to have it back then," says the managing director. Although another ten years would pass before the brand-new HEDELIUS was actually purchased, the visit to Emsland still resonated. The increasing importance of automation as a competitive factor finally prompted him to revive contact with HEDELIUS.

"You have to learn automation first"

For most medium-sized operating companies, the entry into automated production is nothing less than a turning point. Heinrich Fraune knows this from his own experience: "You don't just create the technical prerequisites and get started straight away. You have to learn automation first, even as an experienced user," he explains the new challenges for his team.

Choosing a suitable automation concept was therefore anything but easy for him. Many discussions, trade fair visits and calculations were necessary in order to make an informed decision: "It took me an hour or two of sleep," says Fraune. "After all, an operation of our size can't afford to simply rush into such an investment decision."

Technology from a single source - and a partner who listens

He is all the happier that his choice is paying off today: in 2022, the ACURA 65 was purchased in combination with the MARATHON SR422 multi-pallet storage system. The combination enables the flexible automation of single parts as well as small and medium-sized series - ideal for the East Westphalian company's production spectrum.

"HEDELIUS is one of the few manufacturers that can offer a machining centre and automation from a single source." Fraune emphasises that this was a key factor in his decision. "I had also been shown many other optional features, but the machine and automation always came from two different manufacturers. But we wanted one contact person for everything."

Having a contact person is one thing - being able to rely on them is another. Particularly in view of the fact that smaller operating companies like Heinrich Fraune's often fall under the service radar of large manufacturers, he feels that he is in good hands with HEDELIUS: "We meet on an equal footing. And if something goes wrong, we get help quickly," he summarises with satisfaction.

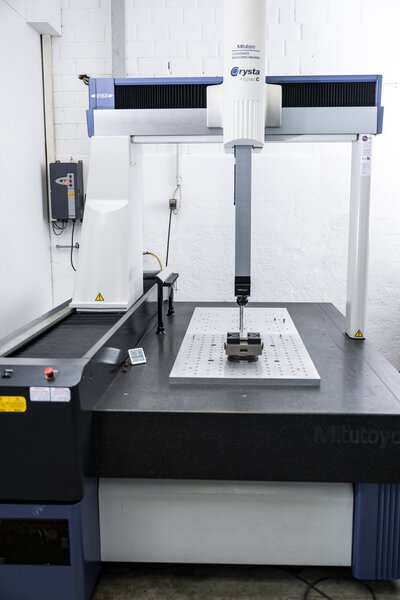

"We wanted one contact person for everything," explains Heinrich Fraune. HEDELIUS is one of the few suppliers on the market to offer high-performance automation concepts from a single source - for example, the ACURA 65 with the MARATHON SR422 pallet automation system.

ACURA masters a wide range of tasks in a small space

The ACURA 65 has a built-in Schunk Vero-S NSE-A Plus 138 zero point clamping system and 65 tool positions in the machine as standard. In order to be able to draw on the full capacity for all production tasks, a 180-station STANDBY MAGAZIN was also purchased - meaning that a total of 245 tool positions are available. For good reason, as the range of materials processed extends from aluminium and plastic to high-strength titanium - not to mention the variety and complexity of the parts produced.

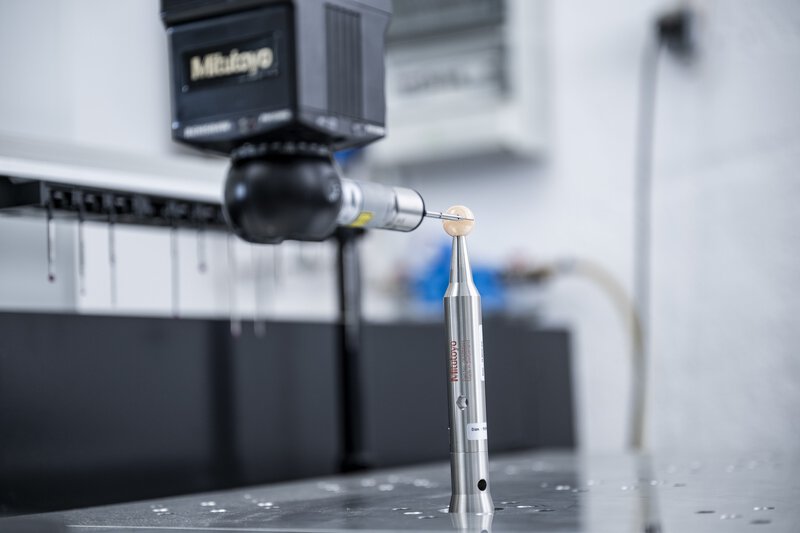

With travel paths of 700 x 650 x 600 mm (X/Y/Z), the ACURA 65 opens up a wide range of production options in the smallest of spaces. And its technical equipment leaves nothing to be desired: Tool breakage checks, 3D measuring sensors and direct length measuring systems help to permanently meet the strict tolerance requirements of Fraune's customers while achieving long tool lives.

Fraune was particularly impressed by the trochoid milling results: "We milled a cubic workpiece from a round blank for a customer in the motorsport range. The machine really shone there." Orders like this show: The requirements are high, but the ACURA 65 delivers reliably.

"The machine runs through us"

Loading from the left-hand side means that the processing area of the ACURA 65 remains fully accessible at all times. "As a rule, the machine runs through anyway, even at night and at weekends," explains Fraune. It is mainly used to produce series parts with batch sizes between 1 and 1000. "In practice, however, we usually start with around 15 to 20 units." The connected MARATHON SR422 pallet automation system offers space for 22 pallets, each measuring 400 x 400 mm. The ergonomically designed storage/retrieval station can be rotated and enables pneumatic locking of the pallet on the Loading station. An integrated monitoring sensor checks whether the pallet is present and correctly clamped.

New orders and relieved employees

"The ACURA with automation can do as much as two entire machines," he says, categorising the leap in productivity, which is primarily made possible by the drastically reduced tooling times. "Of course, this is also a huge relief for our colleagues in production." The expansion of the machine park has also made a lasting impression on customers: "The system has brought us new customers and orders," he says happily.

Conclusion: He and his team have mastered the entry into automation brilliantly - with HEDELIUS.

Gallery.

HEDELIUS machining centres & automation solutions from the customer.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.