News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

With the ACURA 65 and ACURA 85, HEDELIUS has already set standards in the range of 5-axis machining centres with rotating/swivelling table. Now comes the ACURA 50, a new model that impresses with a compactness that is unrivalled with its amazingly large travel paths.

It is hard to deny that automation is finding its way into the factory floor and is an important part of manufacturing concepts. Large companies in particular are often already very advanced in this area. Small and medium-sized companies, the customer base of the northern German family business HEDELIUS, must also follow suit. The mechanical engineering company from Meppen wants to provide support.

As part of the market launch of the compact 5-axis machining centre ACURA 50, HEDELIUS is also launching the ACURA 50 EL, the automatable version of the high-performance machine for small workpieces. The North German family-owned company has focussed on an important detail that can significantly increase production efficiency.

Seeing machines under chip, talking shop, networking - for three days, the machining centres were once again buzzing in the large demonstration centre at HEDELIUS and many of the 300 or so visitors clearly enjoyed feeling the trade fair atmosphere again after the long corona-related break.

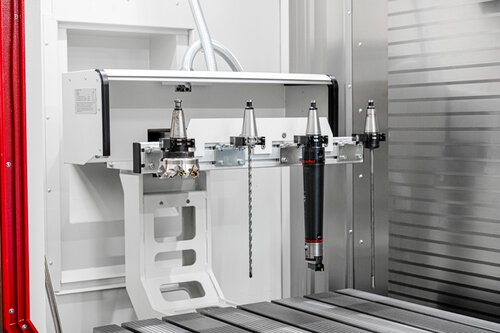

If very long tools such as deep hole drills or tools with a large diameter such as disc cutters or spindle tools are required in a HEDELIUS machining centre, the pick-up magazine is the solution.

Fourteen 3- and 5-axis machining centres and four automation solutions are available for individual, interactive live presentations in the HEDELIUS demonstration centre. Follow our experts around and into the machine and ask your questions.

Despite the coronavirus crisis, HEDELIUS Maschinenfabrik considers itself to be well installed, meaning that both product developments and investments in infrastructure are continuing as planned. For example, the company is currently expanding its office capacity at its headquarters in Meppen by 650 square metres.

HEDELIUS Maschinenfabrik GmbH and its local sales partner Promas BV organised a customer day for interested parties and customers from the Netherlands and Belgium on 16 January.

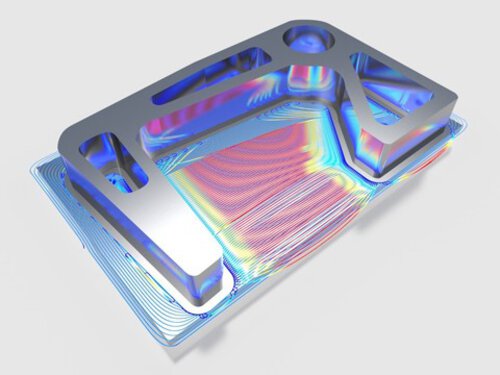

Whirling milling (or trochoidal milling) stands for highly dynamic milling with a high chip volume. Until now, this function was only optimal for slotting. HEIDENHAIN is changing this with a new optional feature for the TNC 640: Optimised Contour Milling (OCM) makes the idea of trochoidal milling available for a much wider range of applications. In addition to roughing open and closed pockets and islands of any shape, OCM also offers cycles for finishing bottoms and side walls.