S&S Schliess- und Sicherungssysteme GmbH | TILTENTA 11- 2600

Field of application: Metalworking, rail vehicle industry

Company headquarters: Mühlhausen, Germany | Employees: 200

For the fifth time HEDELIUS

With around 200 employees in Mühlhausen, Thuringia, Schliess- und Sicherungssysteme GmbH, or S&S for short, is a medium-sized specialist for system solutions in the rail vehicle industry. Founded in 1948, the company has grown from the tradition of a locomotive repair workshop to become a global supplier of doors, steps, partitions, evacuation and fire protection systems for trams, regional and high-speed trains. A true hidden champion that has now opened its doors to HEDELIUS for the fifth time with the TILTENTA 11-2600.

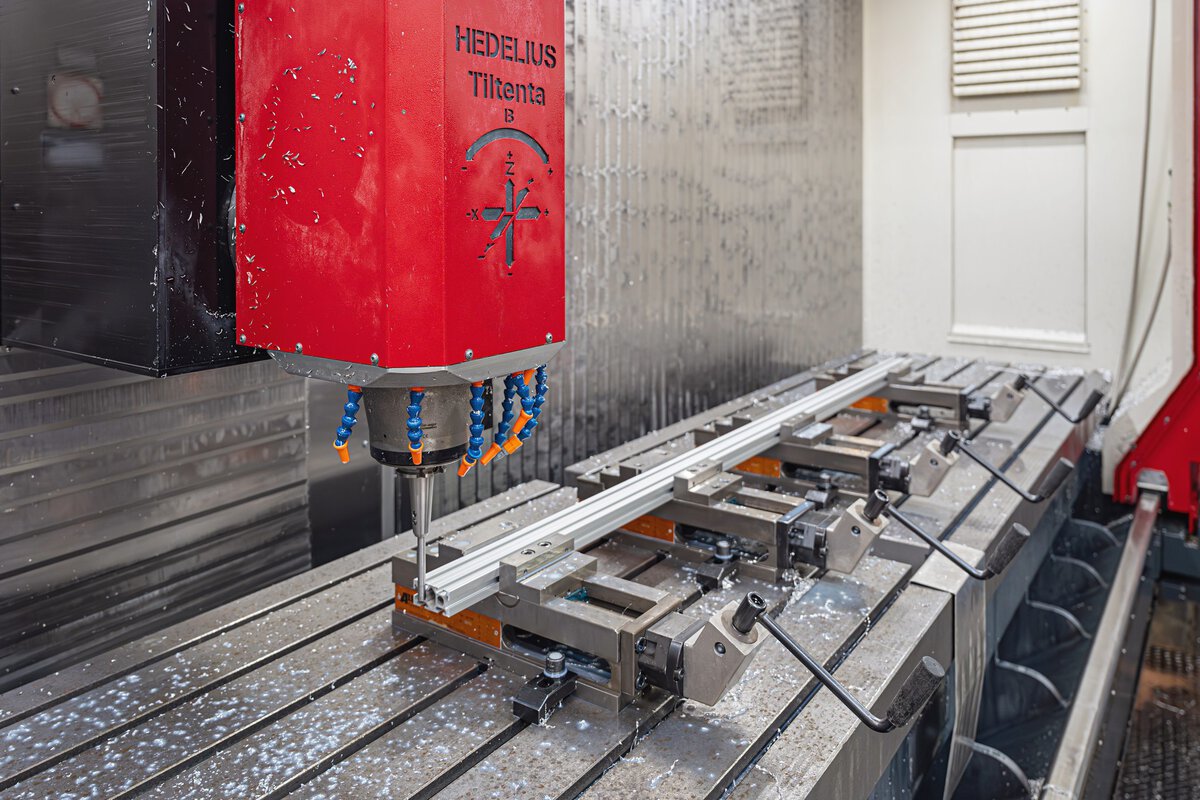

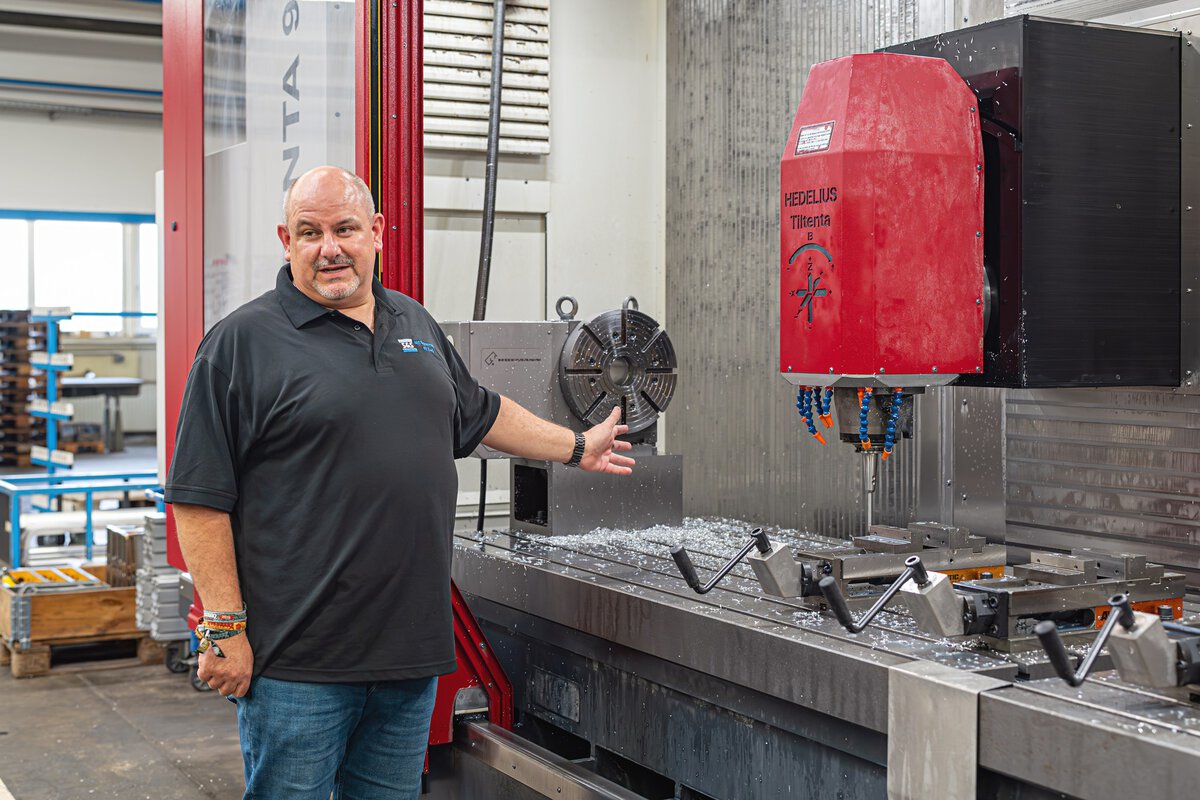

At S&S, the TILTENTA 9-3600 is mainly used to produce large components such as door leaves, window frames or - as seen here - profiles for partitions.

"Safety on the train".

Since 2021, the company has been jointly managed by Jens Meyer as technical managing director and Mareike Hilke as commercial managing director. Complete systems are supplied. True to the company claim "With safety on the train", fire protection, among other things, plays an essential role. The machining of such high-quality components requires machines with high precision and flexibility, especially for individual and small series production, as is typical in the rail vehicle industry. This is where HEDELIUS machining centres are used specifically to produce precise components for sliding doors, evacuation platforms and fire doors.

Quality work from Thuringia is in demand worldwide

The rail vehicle industry accounts for 98 per cent of S&S's business: "Our products are installed on every continent, even at the South Pole," explains Jens Meyer. No wonder, because the Thuringian company's broad portfolio is unrivalled even on a global level: "With a few exceptions, we offer practically everything from a single source," he explains. In order to gain a foothold in the North American market, a sister company, S&S Train Parts LLC, was founded in Dallas, Texas, in 2024. This is because railway projects in the USA require a certain amount of value creation to take place in the country. S&S had already been active in North America via partners since 2016. The new company has significantly professionalised market access.

TILTENTA 9: Precision for large-format components

The breadth of the product portfolio is also reflected in the wide range of component sizes, which are manufactured according to strict specifications. The larger parts include window frames measuring up to 1400 x 1100 mm. A TILTENTA 9-3600 from HEDELIUS was purchased in 2020 precisely for such tasks. The 5-axis machining centre was tailored precisely to the requirements at S&S, including a special vertical rotary table with a vertical three-jaw chuck in the C-axis, which was implemented as a customer-specific special request. An example of how HEDELIUS realises individual requirements in a solution-oriented manner. "You get significantly more out of it than on the old machines," says a satisfied Michael Nonn, head of the chipping department at S&S. "Other machines can't run at 10,000 or 11,000 revolutions continuously. This enables us to use the tools in accordance with the manufacturer's specifications." However, he is not only impressed by the output, but also by the solid construction of the TILTENTA 9-3600: "The machine has a very robust design and is therefore unaffected by malfunctions."

One machine, many possibilities.

With its generous X travel path of 3600 mm and the integrated swivelling spindle concept, the TILTENTA 9-3600 offers ideal conditions for flexible 5-side complete processing of large-format components such as door leaves, window frames and door rails. The swivelling area of -5 to +98 degrees enables a wide range of machining operations without reclamping. A clear advantage for frequently changing geometries and small batch sizes. The TILTENTA 9-3600 primarily processes aluminium and stainless steel - materials that are particularly in demand in the rail vehicle industry due to their specific properties. The integrated 60-cavity tool magazine, which allows quick access to a wide variety of tools at any time, ensures economical processes. The TILTENTA 9-3600 therefore fits seamlessly into the highly dynamic single parts and small series production at S&S.

The special rotating table of the TILTENTA 9-3600 with horizontal NC rotary table in the A axis was realised by HEDELIUS as a customer-specific special request.

ACURA 65: More series capability through automation

In 2024, S&S made a targeted investment in automated series production and added an ACURA 65 to its machine park. The compact 5-axis machining centre was combined with a BMO Platinum 50 workpiece automation system and a 180-position STANDBY tool magazine. A configuration that is designed for a high variety of parts with consistently high quality and process reliability. "Automation allows us to efficiently figure larger series. The machine runs continuously," explains Michael Nonn, pointing to the glass clamp holders that are currently being produced on the ACURA 65. These are used to fix windows in railway vehicles and are typically produced at S&S in quantities of between 600 and 1000 units per series. In addition, small housing parts, door handles and lock plates are regularly machined on the ACURA 65. These are all components that require high repeat precision, tight tolerances and clean surfaces.

Manual production and flexible retooling

With an X travel path of 700 mm and a rotating/swivelling table mounted on both sides, the ACURA 65 enables precise, highly productive machining of even complex geometries. The connection to the BMO Platinum 50 robot cell enables unmanned production of entire series, while the additional STANDBY MAGAZIN with 180 additional tool positions supports flexible retooling and significantly reduces tooling times. This ensures high machine availability even with changing component types and short delivery times.

TILTENTA 11: Transparency in decision-making

The original plan was to expand the automation solution: In addition to the ACURA 65, a second machine, an ACURA 50, was to be connected to the BMO robot cell. However, as another milling machine had to be replaced at short notice, the priorities shifted in favour of a TILTENTA 11-2600 - now the fifth machine from the Emsland manufacturer to be used in Mühlhausen. The decision was made after intensive internal consultation: In addition to Michael Nonn, his deputy, Klaus Meixenberger, was also involved in the selection process. In addition to the technical parameters, the decisive factor was the very precise geometry specifications for future components. HEDELIUS impressed with its transparent approach: "HEDELIUS created videos of test machining for us. This allowed us to make sure that everything would fit," reports Nonn. Like all models in the series, the new TILTENTA 11-2600 is characterised by a generous work area, the integrated swivel spindle concept and powerful 5-axis complete processing in just one set-up. A real gain in efficiency, especially for complex components such as window frames: "At the moment, for example, we still have to pick up the windows several times. On the TILTENTA 11, one clamping operation is enough," explains Nonn.

Positive experiences create trust

The connection to HEDELIUS at S&S goes back a long way. The first two machining centres, two BC 40s, ran reliably in three-shift operation until a few years ago - for well over 20 years. "When considering the service costs incurred over the life cycle, the two machines performed well in comparison to others," reports Michael Nonn. Positive experiences like these have created trust. Today, S&S particularly appreciates the medium-sized structure of the machine manufacturer: short distances, quick help, communication at eye level. "When we talk on the phone, it's a good working relationship. We can speak openly with each other," says Nonn. The technical support is also impressive: "We always get help quickly."

Machine operator Mostafa Hashemi enjoys working on the TILTENTA 9-3600.

Productivity instead of showroom

For Jens Meyer, it's not just the technology that counts, but above all the acceptance of the employees: "I don't work on the machine myself. But if the operators don't enjoy their work, I don't enjoy it either." The practical approach of HEDELIUS, the robust version of the machines and the focus on functionality fit in well with the company's philosophy: "A beautiful design is not enough - the machine must also deliver." There is also a clear commitment to the domestic industry: "We try to buy as much as possible in Germany," emphasises Meyer. With the new TILTENTA 11-2600, S&S is not only expanding its machining capacities, but is also setting an example for long-term partnership and sustainable investment in modern, productive manufacturing. Or as Michael Nonn opens the point: "We hope that HEDELIUS will continue as before."

HEDELIUS machining centres &

The customer's automation solutions.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.