Metallverarbeitung Uwe Ebertz GmbH | TILTENTA 7-3200

Field of application: Contract manufacturing | Company headquarters: Sinn-Fleisbach, Germany | Employees: 10

The innovative metal processing company Uwe Ebertz GmbH is based in Sinn-Fleisbach, Hesse. Since its foundation, the family business has undergone a transformation from a sheet metal processor to a comprehensive metal processing service provider. It uses modern technologies made in Germany, such as the Tiltenta 7-3200 machining centre from HEDELIUS Maschinenfabrik GmbH.

Three large pictures with racing motifs hang in Uwe Ebertz's office. An orange-coloured sports car and the pit crew are closed on one of them. Mr Ebertz is standing in the middle. The pictures and several trophies are evidence of the racing enthusiasm of the energetic managing director of Metallverarbeitung Uwe Ebertz GmbH (MUE). He has taken part in the 24-hour race on the Nürburgring several times, has competed with many of the greats of German motorsport and has achieved considerable success. He also transfers this sporting competition and ambition to his company. He has continuously developed the company into a successful metalworking company with a high level of vertical integration and quality standards. Today, the family business employs ten people and manufactures metal products in a single shift for customers from the mechanical engineering, vehicle construction, rail transport and construction machinery industries throughout Germany.

Early investment in laser processing.

It all started over 23 years ago in Sinn-Fleisbach, Hesse. "I founded the company in 1995, when my employer at the time went bankrupt. That was the deciding factor for me. I kept in touch with the customers and set up my own business," says Mr Ebertz, giving a brief insight into the early days of his company. Initially, sheet metal parts were produced on folding benches, then the company invested in a laser. "I bought a Trumpf laser, which was still something special back then. There weren't that many companies that could do laser processing," says the owner. Even back then, Metallverarbeitung Uwe Ebertz GmbH was at the forefront of new technologies and developments. The range of services has been continuously expanded over the years. In addition to edging, bending and laser processing, the company now also offers milling, turning, deep drawing and welding. "Over time, customers have demanded more outputs from a single source. Increasingly, sheet metal parts also had to be drilled and threaded or entire assemblies had to be manufactured," says Uwe Ebertz, explaining the expansion of the value chain. Thanks to a broad range of services, it is possible to obtain different products from a customer and deliver them in a reasonable time and quality. Mr Ebertz explains: "In the beginning, we bought in machining services, but they were not available on the market in the quality or speed we needed. Sometimes we had to wait several weeks for a product to open and then the quality wasn't right."

TILTENTA 7-3200 for maximum flexibility.

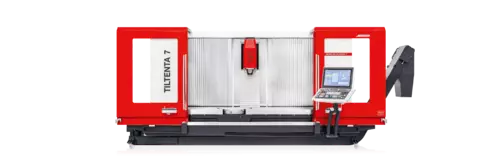

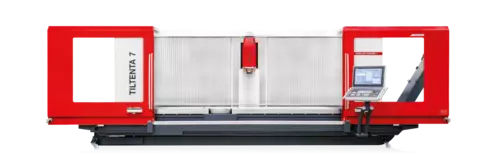

In addition to a high quality standard and a deep value chain, very short and flexible delivery times are one of the strengths of the Central Hessian company. If it is urgent, sheet metal parts are sometimes produced overnight for a customer. A large material warehouse with over 50 types of sheet metal and steels allows MUE to open customer enquiries at extremely short notice. There is usually a little more time for milled parts, but the two milling machines rarely stand still. The most modern machining centre in production is the TILTENTA 7-3200 from HEDELIUS, with swivelling main spindle and Siemens control. The machine, which was purchased in 2018, complements a small, 15-year-old milling machine and, thanks to its large travel paths of 3200 x 750 x 695 mm (x/y/z) and a work area partition, ensures an enormous increase in capacity and flexibility in production. "It fits the volume," says Mr Ebertz succinctly but aptly. "We decided in favour of the machine because it offers us so many possibilities. The work area partition allows us to create two work areas - we can produce in one and set up in the other." The variety and batch sizes of the parts to be closed also make this necessary. The smallest parts on the TILTENTA 7-3200 have dimensions of 80 x 40 mm, while the largest parts reach the dimensions of the travel paths. MUE produces everything from single parts and small series to large series of 8,000 parts per order. "We machine cast parts in large series on the TILTENTA 7 with a tolerance of one tenth, but also aluminium and stainless steel parts with accuracies of one to two hundredths," reports the owner, and the challenges in production become very clear.

Save tooling times with a wide range of accessories.

In order to optimally utilise the machines, production is also kept open. Some customers of the high-performance medium-sized company call off parts at regular distances. These are then pre-produced and stored. This also leads to more flexibility and faster response times to customer enquiries. In addition to the work area partition, further accessories were ordered for the TILTENTA 7-3200. These include an extended swivelling area, an increased rotary table load, a 50 bar pressure booster pump and a standby tool magazine. The large magazine adds a further 180 tool pockets to the standard 33-cavity magazine. A cone cleaning station is also integrated so that tools can be cleaned and oiled automatically. Mr Ebertz is impressed by this magazine: "Thanks to the standby magazine, in combination with the zero point clamping system and the partition, we can significantly reduce tooling times and run series without interruption."

Made in Germany with confidence.

In addition to metalworking, Metallverarbeitung Uwe Ebertz GmbH has built up another mainstay with its own products. MUE manufactures various in-house developed stainless steel gas grills for the catering industry, and a new addition to the range is a high-performance grill with a top heat of 850 degrees Celsius. Many of the components are of course manufactured at MUE. And it comes as no surprise that the company also develops and manufactures its own products for racing. The company currently generates around 25% of its turnover with its own range. It is therefore very convenient that the depth of added value in the company is so high. As with his customers' products, Uwe Ebertz also applies high quality standards to his own products. "Our products are made in Germany, which is very important to me," explains the managing director. This also applies to the products of his suppliers. In the case of the Trumpf laser or the TILTENTA7-3200 from HEDELIUS, it was therefore one of the purchasing criteria that a German manufacturer was behind the product.

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.