19 January 2020

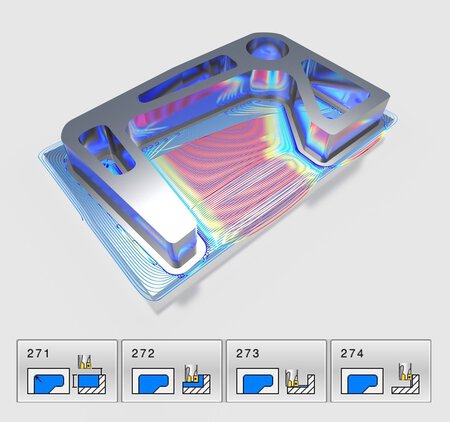

Whirling milling (or trochoidal milling) stands for highly dynamic milling with a high chip volume. Until now, this function was only optimal for slotting. HEIDENHAIN is changing this with a new optional feature for the TNC 640: Optimised Contour Milling (OCM) makes the idea of trochoidal milling available for a much wider range of applications. In addition to roughing open and closed pockets and islands of any shape, OCM also offers cycles for finishing bottoms and side walls.

Like whirling milling, OCM limits the wrap angle and allows milling with the entire cutting edge length. With OCM, the user can programme any contours directly on the TNC 640 in the usual workshop-oriented way. The control automatically calculates the best possible tool paths to ensure that the cutting conditions are constantly maintained. Machining always runs with the optimum cutting values. This not only significantly increases the machining speed - tool wear is also noticeably reduced.

Advantages of vortex milling with OCM.

Less milling pressure for thin-walled components

Higher chip volume

Lower processing time

Better machining of hard materials

Lower heat generation in the component

Lower tool wear

We would be happy to show you the advantages of vortex milling using a practical example in our demonstration centre in Meppen.

More news.

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!

(PDF | EN) The 5-axis machining centres in the ACURA series combine compact design with maximum performance and automation readiness ex factory. Whether single parts or series components up to Ø 900 mm and 1,000 kg are machined with high precision. With innovative technology, generous tool capacity and ergonomic design, ACURA machining centres are perfect for demanding production environments. Download the folder now and discover the full potential of the ACURA!