ERO GmbH | ACURA 65 EL

Field of application: Agricultural machinery technology, contract manufacturing | Company headquarters: Simmern im Hunsrück, Germany | Employees: 270

This video requires your consent to third-party cookies. Privacy settings

Further informationERO GmbH from Simmern in Hunsrück is a prime example of a family business that has grown healthily. And it is deeply rooted in the region in the truest sense of the word. Founded in 1965 by farmer Heinz Erbach, the company initially builds modern stables. A few years later, the founder's brother-in-law, the trained winegrower Herbert Roth, joins the company. The name ERO is created from the initials of the two innovative-minded relatives.

A success story that began 50 years ago.

Innovative is a word that is often used to describe companies. But here it really fits the point several times over.

A success story began 50 years ago with the first machine for viticulture, the ERO roundabout harvester. The introduction of the first grape harvester in 1981 was another milestone in the company's history and was largely responsible for its continuous growth. In recognition of its continuous development, the company has been honoured several times, e.g. with the German SME Innovation Award and the Enovitis Award from Italian winegrowers.

Today, around 270 employees work for the company, most of them at the factory in Simmern/Hunsrück, which was only newly built in 2018.

ACURA 65 EL: also able to produce unmanned parts.

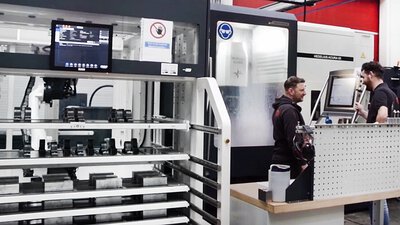

"In the modern halls with more than 15,000 square metres of production space, we naturally want to produce using the latest and best methods," says Jan Inboden, who is responsible for the smooth running of operations at ERO. He is constantly in dialogue with the employees and is always on the front line. "We have a particularly wide range of components here with batch sizes from 1-1000 units," explains Inboden. He stands in front of the ACURA 65 EL from HEDELIUS and looks very satisfied. "This is exactly what we were looking for. A 5-axis machining centre that can also produce parts in a ghost shift - i.e. unmanned. And that works smoothly here with HEDELIUS in conjunction with the robot automation from BMO."

Inboden pulls out a workpiece and explains how a fit was milled. Even after many dozens of pieces, it always looks the same and has "above all, perfect quality in terms of dimensional accuracy and surface quality."

Minimise the time and cost factor of tool set-up.

Of course, smaller batch sizes are also produced on the ACURA 65 EL. To ensure that the changeover from one job to the next runs quickly and smoothly, it is important to have quick access to the required tools. Searching for and swapping tools only causes unnecessary downtime and reduces productivity.

But the HEDELIUS has also convinced the chipping experts at ERO. The standby magazine has space for 180 tools. "We can therefore minimise the time and cost factor of retooling to an open minimum!"

A well-oiled team: HEDELIUS + BMO.

At the end of the day, the automation system is tooling with new, different raw parts so that the ERO specialists can also enjoy their evening off. The 6-axis robot from BMO Automation then changes the required clamping device in the machining centre and automatically inserts the workpieces at the connection.

This leaves time for a good drop of wine, harvested with ERO harvesters, of course. That's the deeper meaning - if everyone benefits in the end. "Even those who have never heard of the ACURA 65 EL before," smiles Inboden. It looks like he already has the next ideas in mind. As I said, innovation is not just a buzzword here ...

HEDELIUS machining centres of the customer.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.