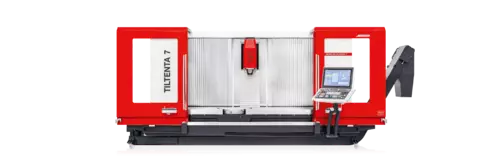

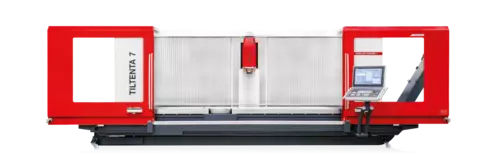

Wendt Maschinenbau GmbH & Co. KG | TILTENTA 7-4200

Field of application: Machine and plant construction | Company headquarters: Georgsmarienhütte, Germany | Employees: 110

The town of Georgsmarienhütte is named after the local steel company, which grew out of the local mining industry. Today, mining vehicles, special machinery and medical technology are manufactured in one of the former industrial halls of Georgsmarienhütte. Wendt Maschinenbau GmbH und Co KG manufactures a wide range of parts, machines, steel structures and devices on behalf of customers here and at another location.

The company was founded in 1992 with four employees and has since grown into a family business with 110 employees, fourteen of whom are trainees. Many machine parts, special machines, steel constructions and operating equipment are not only manufactured at Wendt, but are also planned, designed and later assembled and maintained at the customer's premises. A complete service that has already been utilised by companies from a wide range of industries. "Sometimes all we get from the customer is the CAD drawing of a machine part. We use this to design the necessary devices and integrate them into the production line," explains Managing Director Michael Wendt. The references include special machines and conveyor systems for the assembly of rubber products as well as clamping devices for production lines with welding robots in the automotive industry.

Single parts and small series.

Many of the customised designs are manufactured specifically for one application. "Our batch size is one, a series starts with a quantity of two," says Wendt, smiling as he opens the production situation. "At the same time, 90 per cent of all parts are machined by us in some way, almost nothing goes out unmachined". Almost all of the workpieces are produced in-house, including on four HEDELIUS machining centres. "We manufacture a wide range of workpieces on these machines. It's perfect for us that they can do it all," says Wendt. On the one hand, the highest precision is required, as with the cutting rollers on a production line for the production of paper bags. They are checked several times for any imbalance because the rotating blades are accelerated to around six times the speed of sound. On the other hand, massive machine parts for special applications in the automotive industry also have to be milled and larger welded assemblies machined.

Flexible thanks to powerful machining centres.

Wendt Maschinenbau works with various HEDELIUS machining centres, usually in oscillation mode, for the very different tasks. The RS 505 K18 from the RotaSwing series combines a rotating/swivelling table for 5-axis machining and a fixed machine table for 3-axis machining in one work area. Designed as a universal production island, it is ideal for highly flexible production. There is another RotaSwing in production alongside a HEDELIUS BC 100 with a 2500 mm X travel path for 3-axis heavy-duty machining. The BC series impresses with its high output in heavy-duty machining, as the main spindle achieves up to 10,000 revolutions per minute with 55 kW drive power. Special parts for self-pierce riveting technology in the automotive industry are milled here. The parts are further machined in oscillation mode on the TILTENTA 7 with 4200 mm X travel path, a swivelling spindle machining centre for 5-axis simultaneous machining.

Convinced by the service.

"The first machine is sold by Sales, the next by Service," explains Managing Director Wendt. "We are very satisfied with the HEDELIUS machines, they are good at chipping. But the service staff also do a great job". After all, even the best machine can break down from time to time. "What counts for me is how you deal with it. And at HEDELIUS you can also call on Fridays and get support as quickly as possible".

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has designed the smallest size in the TILTENTA series to be significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.