D+P Dosier- und Prüftechnik GmbH | TILTENTA 7-Single

Field of application: Machine and plant construction | Company headquarters: Nördlingen, Germany | Employees: 60

Since it was founded in 1986, D+P, Dosier- und Prüftechnik GmbH has been developing and producing highly complex standard products and customised systems for applying and dispensing liquids, greases and pastes as well as for assembling components and testing functions. The products of the 60-strong company are mainly used in the automotive and electrical industries as well as in mechanical engineering, assembly technology and the air and space industry.

The second-generation family business is a success story. Through continuous growth, the company from Nördlingen in Bavaria has become a highly specialised and high-performance supplier of special machines in the field of dosing and testing technology. D+P offers national and international customers complete solutions from design and development to commissioning with comprehensive service. All systems are specially designed to meet the high customer requirements for quality, precision and reliability. The medium-sized company relies on a high level of expertise, innovation and modern production technology.

Customised production of the systems.

No two customised special-purpose machines are the same, which means that different requirements are placed on the components for each system. Only the basic material, aluminium, is almost always the same. As a result, the components required are usually single parts or, rarely, small series. "We face many different challenges in special machine construction. We often need single parts or very small series of up to a maximum of 20 components," says Production Manager Werner Schnell, describing the situation in production. On the other hand, components for line products also have to be manufactured, including contract manufacturing for customers. These very different requirements, particularly in terms of flexibility, have to be mastered in production.

Flexibility in production.

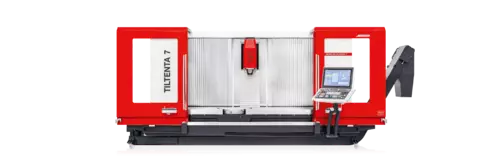

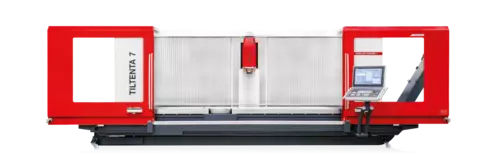

D+P therefore relies on a 5-axis machining centre from HEDELIUS, a TILTENTA 7 Single with standby magazine, to machine the larger aluminium parts. The tool magazine has space for 180 tools. "The decisive factor for us was the great flexibility offered by the standby magazine with space for a large number of different tools," explains Werner Schnell. This means that the tools are always available directly at the machine for the various processing steps of the individual components. Searching and tooling times are almost completely eliminated. Other criteria in favour of the machine from HEDELIUS were its high accuracy, compact design and large Y travel path. "Not every machine manufacturer offers a Y travel path like this," says Werner Schnell. "I was satisfied with the overall package, even though the table load has not yet been utilised." The dosing and testing specialist from Bavaria has also had good experiences with the service provided by HEDELIUS. The short response times and good support from HEDELIUS have been well received.

HEDELIUS machining centres of the customer.

In accordance with market demand, HEDELIUS has made the tried-and-tested TILTENTA 7 significantly more compact with almost identical performance parameters. Discover our optimised bestseller: TILTENTA 7 NEO.

More testimonials.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.

Heidkamp Metallbearbeitung in Hüllhorst** relies on maximum flexibility, quality and adherence to deadlines in the production of milled parts. The 5-axis machining centre ACURA 65 EL from HEDELIUS, combined with a large tool store, pallet pool and GRESSEL centric clamps, ensures short tooling times, automated individual and small series production and reliable processes, even with complex components and tight delivery deadlines.