News from HEDELIUS Maschinenfabrik.

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

The powerhouse for heavy-duty machining - a TILTENTA 10-3600 from HEDELIUS Maschinenfabrik in Meppen - has been in the production hall just outside the gates of Eindhoven for a year now. The long-established Dutch company De Rooy machines very large, often complex workpieces from a wide variety of materials.

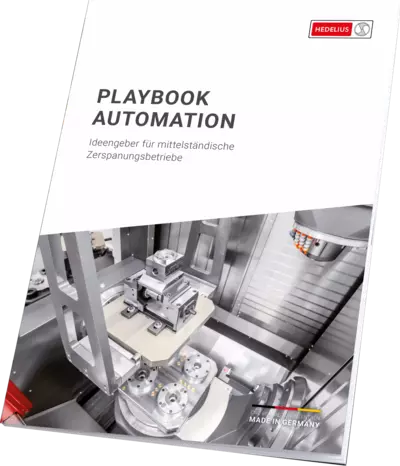

Tooling optimisation and automation mean benefits for entrepreneurs and employees alike. Automation not only reduces tooling times and increases production, but also allows you to utilise previously unproductive times efficiently. We are happy to support you on your open road to more productive production.

"Never change a winning team" - this could be the headline for the collaboration between HEDELIUS Maschinenfabrik and automation specialist BMO at the Dutch manufacturing company Edumar Metaalbewerking. On the way to even more flexible unmanned production, the choice has now been made for the second time in favour of a joint solution from the two manufacturers.

(PDF | EN) We are very pleased to be able to introduce you to our company's sustainability efforts with this brochure. As a family-run, internationally successful manufacturer of CNC machining centres, we have a responsibility - not only towards our customers and partners, but also towards the environment and future generations.

We are pleased to be able to present a new highlight to customers in our technology centre in the future: the beginner-friendly automation RoboJob Mill Assist. The compact workpiece automation with 6-axis robot offers many advantages, especially for beginners. Get an impression of the user-friendly and productive robot automation with our user video.

What could be better for a chipper than perfect chips? In super slow motion at 600 frames per second, chipping on a TILTENTA 11-2600 looks even more impressive. Discover the art of chipping with our latest slow motion video.

We look back on two successful trade fair days with enriching exchanges. It was a special pleasure for us to welcome more than 500 visitors** on 24 and 25 April in Meppen** to this year's in-house exhibition. A big thank you goes to...

Your production process is as individual as your company itself. That's why we offer you a wide range of automation solutions: From precise pallet and workpiece handling to hybrid solutions and advanced linear interlinking systems. We are at your side to successfully close your path to automation.

Despite the current subdued mood in the German machine and plant engineering sector, HEDELIUS is investing in the expansion of its production capacities. In this interview, Managing Director Dennis Hempelmann reveals how HEDELIUS managed to make the past financial year its most successful yet and how he personally assesses the growth prospects for 2024.