The digital twin.

The next level of manufacturing technology.

The digital twin marks a new era in manufacturing and is revolutionising our idea of the production of the future. Instead of emulators, more and more software platforms rely on real CNC technology provided by control manufacturers for virtual environments. This means that the operating system of the machine is now available in a software environment. Machine tool manufacturers can therefore not only provide their customers with a physical machine, but also an exact digital copy in the virtual world, a digital twin.

Technological basis.

Full functionality, digitally mirrored.

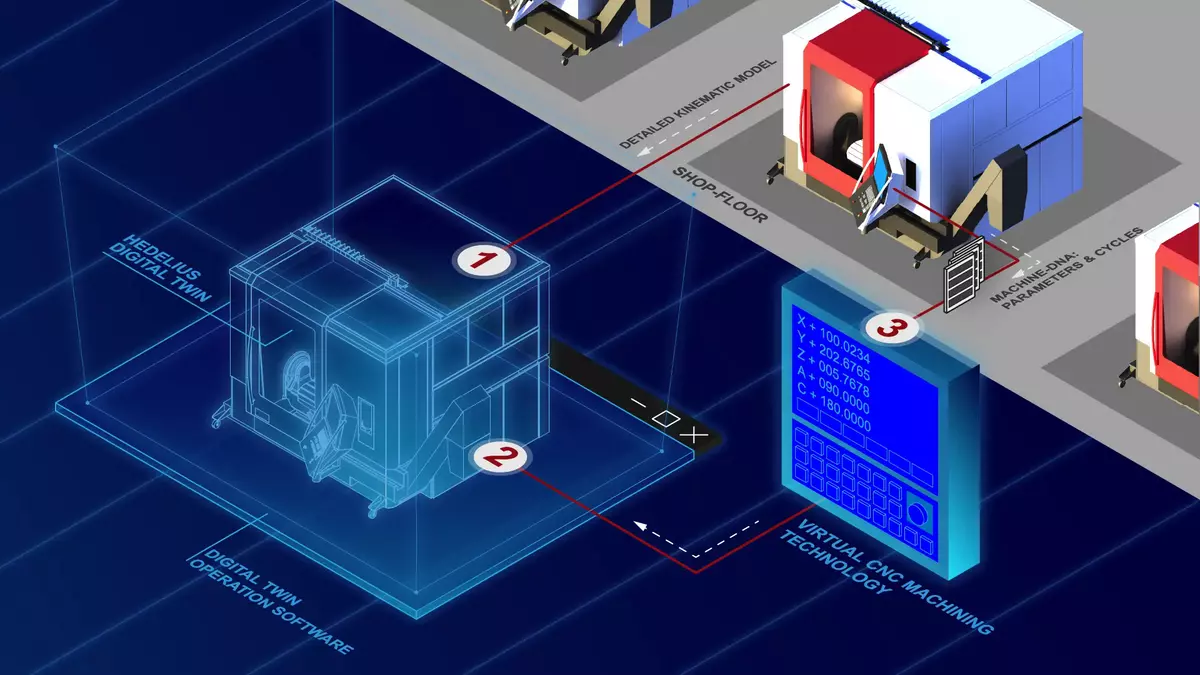

The basis of the digital twin is a detailed kinematic model that includes all NC axes, interference contours and machine features. This model is connected to a virtual CNC control that has the identical parameterisation and complete cycle scope of the real machine. This ensures that the digital twin has the full range of functions of the physical machine and can be operated identically. This not only opens up efficiency gains, but also strategically important areas of application.

Properties and functions.

Maximise productivity right from the start.

With the digital twin, NC programs can not only be simulated, but the entire run-in and optimisation process can be fed-through directly in a virtual environment. This significantly improves work preparation and reduces downtimes in production. As the digital twin uses exactly the same parameters as the real machine and always knows the current machine status, the virtual CNC control executes all NC blocks identically and with the realistic machine dynamics - regardless of the complexity of the NC syntax or the cycles used.

The result: Error-free NC programs, free from collisions and syntax errors. Companies benefit from immediate production release and the ability to close individual components unmanned and automatically.

This video requires your consent to third-party cookies. Privacy settings

Further information

1 Developing a post-processor | 2 Creating and optimising initial CNC programs

3 Training and knowledge building | 4 Stabilising machining processes and machine operation

Virtual commissioning.

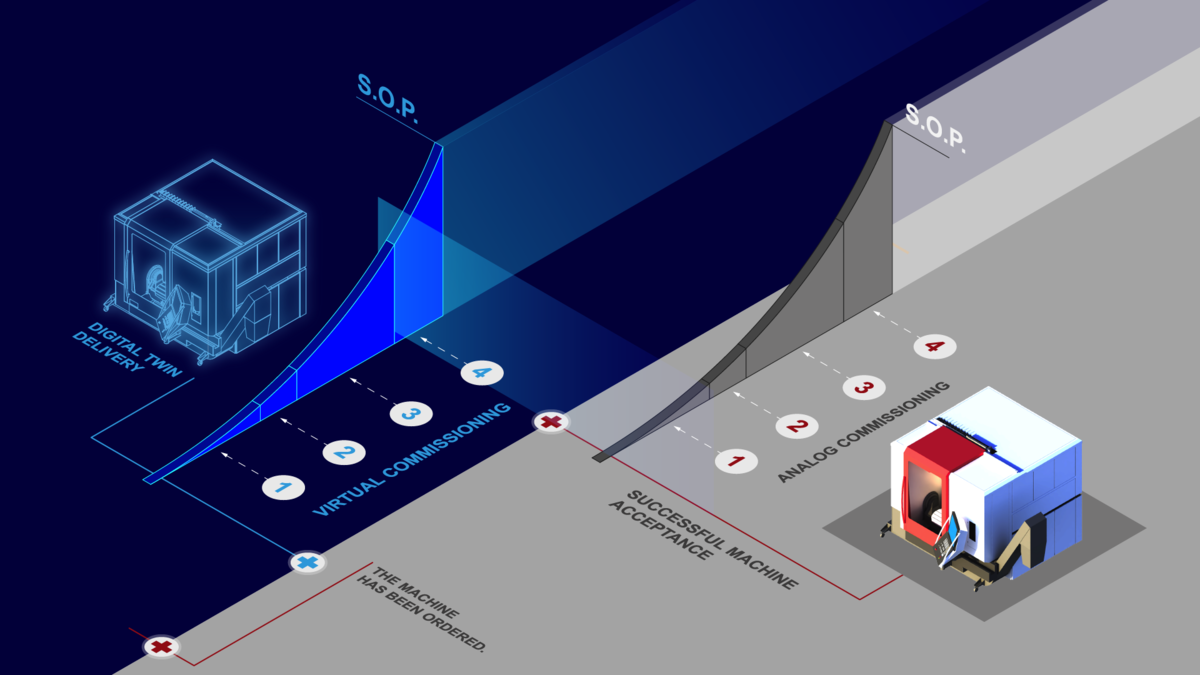

Faster ramp-up phases.

When introducing new machines, the digital twin offers significant advantages as it optimises the entire commissioning process. Long before the machine is physically delivered, the digital version can be used to create, test and optimise initial NC end programs. This allows companies to work with their CAM partners at an early stage to develop post-processors and validate machine processes. At the same time, employees can already be trained in the virtual environment, ensuring seamless knowledge transfer and a smooth transition to production. This forward-looking use of the digital twin significantly shortens the ramp-up phase of a new machine, reduces downtimes and enables faster production start-up with maximum efficiency.

Advantages of a digital twin.

Open up new possibilities.

With the digital twin, you have the safety of knowing that your NC programs will run flawlessly on the machine. This allows you to gain process reliability and increase productivity. The absolutely realistic simulation with the digital twin can also be used when preparing quotations and planning orders. A digital twin of your machine also offers further advantages for the training and further education of personnel.

Solutions from our software partners.

The choice is yours.

Various software solutions are available on the market for implementing the digital twin. HEDELIUS relies on strong partners with specialised technologies. HEIDENHAIN offers the programming station, a powerful solution especially for the company's own TNC control systems. The company Pimpel, on the other hand, provides CHECKitB4, a cross-platform software that supports both Siemens and HeidenHAIN control systems.

CHECKitB4 is the versatile platform for the digital twin of your machine tool - compatible with Siemens and Heidenhain control systems. In addition to Sinumerik One, CHECKitB4 also supports Sinumerik 840D, Heidenhain iTNC 530, 640 and the latest TNC7 control system, offering maximum flexibility for virtual CNC applications. NC programs can be realistically simulated, run in and optimised - for collision-free processes, reduced tooling times and efficient training directly on the virtual machine.

Creating, testing and optimising end programs in the office and on the TNC control in the workshop: HEIDENHAIN offers the programming station for this purpose. It is the exact mirror image of the control and thus offers all the familiar control elements and functions of a TNC. What it does not include: a figure of your machine and your real production environment. HEDELIUS provides you with this with the digital twin. It opens up the actual kinematics, parameters and functions of your HEDELIUS machine to the HEIDENHAIN programming station.

More news.

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!