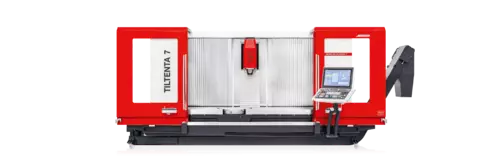

VITRONIC Machine Vision GmbH | TILTENTA 7-2600 NEO

Field of application: Machine vision systems | Company headquarters: Wiesbaden, Germany | Employees: 1,400

Flexible chipping and fast set-up in prototype construction

In addition to various clamping technology modules and lathe chucks for workpiece clamping, the Wiesbaden-based company Vitronic also uses tool holders with hydraulic expansion technology. The modular basis and precision interface to the machine table is the VERO-S modular zero point clamping system. It enables the user to realise universal and precise clamping and achieve a height machining output.

Lukas Seibel, Machining Technician/Application Technology CAD-CAM at Vitronic Machine Vision, Marco Sauer, Technical Consultant Clamping Technology Division at Schunk and Darius Adamski, Project Manager Application Technology CAD-CAM (from left to right) in front of the high-performance machining centre of the TILTENTA series from HEDELIUS at Vitronic's factory in Wiesbaden. (Image source still SCHUNK SE & Co. KG)

Part production in prototype construction has special, specific requirements. The focus is on high flexibility and easy adaptability of the production environment to enable iterative improvements to the design and functionality of the component. "We work with sample parts and small batch sizes, which is why we have to constantly realise new clamping situations - and do so as quickly and safely as possible," explains Darius Adamski, CAD-CAM application engineer at Vitronic Machine Vision. The prototype construction department of the manufacturer of image recognition and image processing systems at the Wiesbaden site produces housing parts, brackets, heat sinks, mounts and other components for the inner workings of state-of-the-art optical testing and inspection systems. Vitronic's devices are high-tech products for which conventional assembly production and classic machining at a high technical level are essential. "Our machine equipment must be top of the range, it must be broad and flexibly installed so that we can react quickly and work efficiently," emphasises Adamski. "Our approach is not comparable to series production. On the one hand, we need variants for clamping and machining. And secondly, safety is a major issue in the constantly changing situations in order to avoid damages."

Flexible machine equipment thanks to modules from the Schunk modular system

The team led by Darius Adamski found the solution to these requirements during a visit to AMB in 2018. "This visit to the trade fair was a huge surprise for us," emphasises the project manager. "At the Schunk stand, we immediately realised that we could find the right solution here." The large selection of clamping devices with all conceivable variants convinced Adamski. "Nobody else has an offer like this!" Previously, he had several different suppliers and contact persons for tool fittings and clamping devices, which required long distances and a lot of time for coordination. "We wanted to put an end to that, because it's completely ineffective. We finally wanted a central point of contact and a direct contact person for our machine equipment. We found that at Schunk - and not only that: we can now open up an unprecedented wealth of components.".

This was the start of a pioneering collaboration. Vitronic equipped the Alzmetall GS 800 five-axis machining centre acquired in 2019 with various modules from Schunk's modular clamping technology system - including the Vero-S NSE3 138 zero point clamping system, various clamps and lathe chucks as well as the Tendo EC and Tendo Slim 4ax tool holders. Flexibility, set-up time optimisation, handling comfort and efficiency have since opened up to a new level. "This variety of clamping devices and jaws has opened up our work to a new level. The extensive Schunk modular system is exactly what we need," says Adamski. And above all, he assures: "The quality is right here."

At the beginning of 2025, it was time to invest in another new machine - a high-performance machining centre from HEDELIUS. The large work area with the infinitely variable swivelling milling head enables the vertical machining of long workpieces. The integrated NC rotary table also enables five-sided machining of heavy-duty parts. The partition creates a three-axis and a five-axis work area for efficient oscillation mode. "We simply copied the Alzmetall equipment for the new machine," reports Lukas Seibel, machining technician and CAD-CAM application engineer at Vitronic Machine Vision. "We were impressed by the fact that we can simply transfer the clamping modules from one machine to another. For us, this means short distances, fast tooling times and ergonomic handling. We can react immediately to new situations in our daily work. With this customisable and scalable machine equipment and the interaction between the two systems, our machining efficiency has received a significant boost," enthuses the young machining technician.

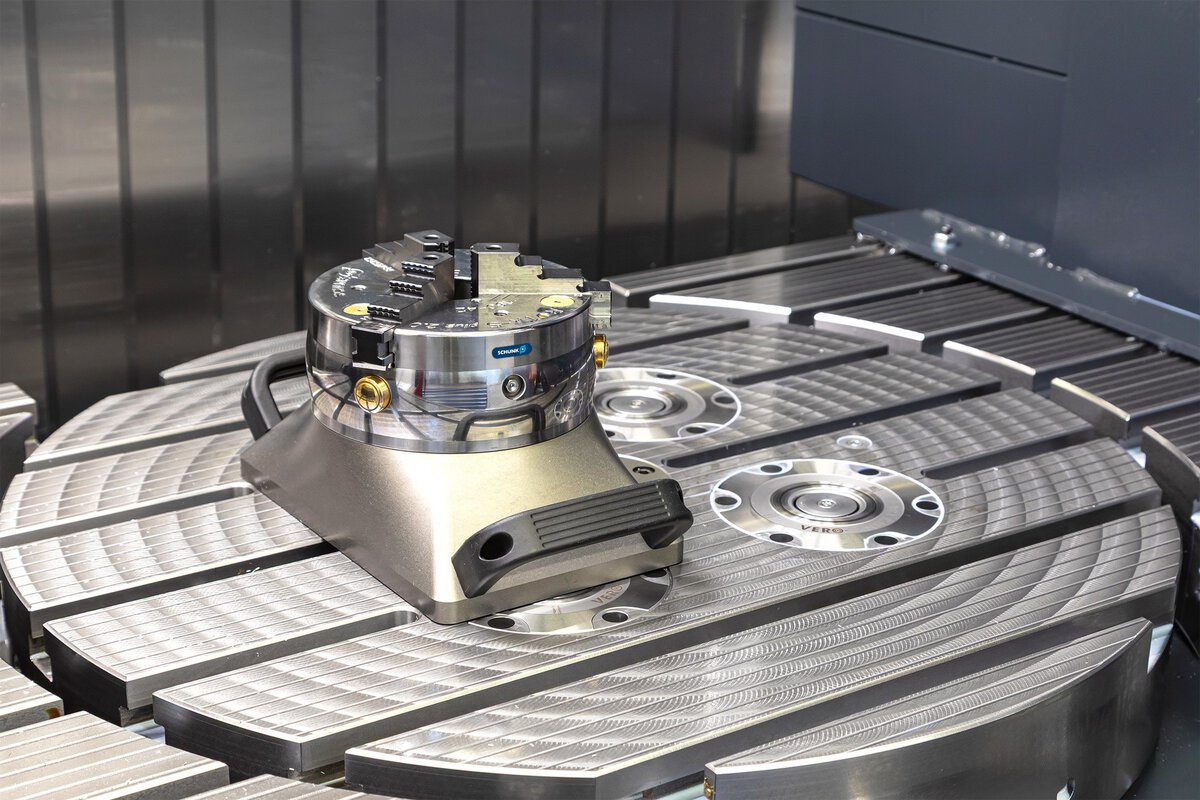

With the fully integrated Vero-S zero point clamping system, clamping devices can be changed quickly and very precisely. The changeover from a 5-axis vice to a three-jaw chuck takes less than a minute. (Image source still SCHUNK SE & Co. KG)

Vero-S zero point clamping system as the basis for fast and flexible set-up processes

The modular basis and precision interface to the machine table is also available on the new HEDELIUS TILTENTA is the modular Vero-S zero point clamping system. "We use it to achieve precise clamping of a wide range of workpiece geometries and set up quickly and efficiently," emphasises Lukas Seibel. The prototype department at Vitronic achieves full machining output with a total of 18 NSE3-138 modules installed. The stainless and sealed modules are equipped with a spring-actuated cone lock that automatically closes the change interface as soon as the clamping pin is lifted out. This prevents the ingress of chips or dirt. This ensures process reliability during machining sequences and a long service life for the clamping station. The dimensionally stable clamping modules can absorb high tilting moments and lateral forces, resulting in extremely rigid clamping without vibrations. In addition, the pneumatic NSE3 modules achieve a high pull-in force that is fully maintained even in the event of a pressure drop.

Fit clamping modules and lathe chucks assembled within seconds

Vitronic uses various clamping modules from the Schunk modular system on the Vero-S clamping station, such as the basic KSC3 125-300 clamping block with console or the slimline Kontec KSX-C2 125-300 five-axis clamping block. Set-up in conjunction with the Vero-S takes just seconds. Schunk has set a new milestone with the fully encapsulated and robust KSX-C2 clamping block - it offers even more flexibility, even fewer tooling times and a safe holder. The jaws can be changed quickly without tools. With a basic clamping stroke of 130 millimetres and reversible jaws to increase the clamping range, the clamping block can be quickly converted to open a new range of parts.

The robust KSX-C2 five-axis vice enables tool-free quick jaw changes and precise six-sided machining. In combination with the Vero-S zero point clamping system, it ensures excellent machining results. (Image source still SCHUNK SE & Co. KG)

Many different quick-change jaws are available. Thanks to active pull-down, precise six-sided machining is possible on the five-axis machine. Users achieve excellent machining results in terms of plane parallelism and squareness. The upwardly tapered outer contour of the KSX-C2 enables good accessibility with standard tools. The operator can infinitely adjust the clamping forces using a torque spanner, for example for controlled forces for clamping sensitive parts. During machining, integrated elastomer damping absorbs any vibrations that occur - resulting in a high surface quality of the workpieces.

The Rota-S plus 160 2.0 manual chuck is also part of Vitronic's modular clamping technology system. Schunk has designed the lathe chuck for a wide range of clamping tasks as a two-jaw and three-jaw chuck, especially for clamping round workpieces. The high efficiency of the wedge bar system and the optimised lubrication system ensure reliable clamping and permanently high clamping forces; users benefit from the machining efficiency. The developers have pulled out all the design stops with the Rota-S plus 2.0: large chuck bore, helical-toothed base jaws, user-friendly quick jaw change system with high repeat precision, functional parts hardened and ground on all sides and visual safety features for maximum operating safety.

Tool holder with pioneering hydraulic expansion technology

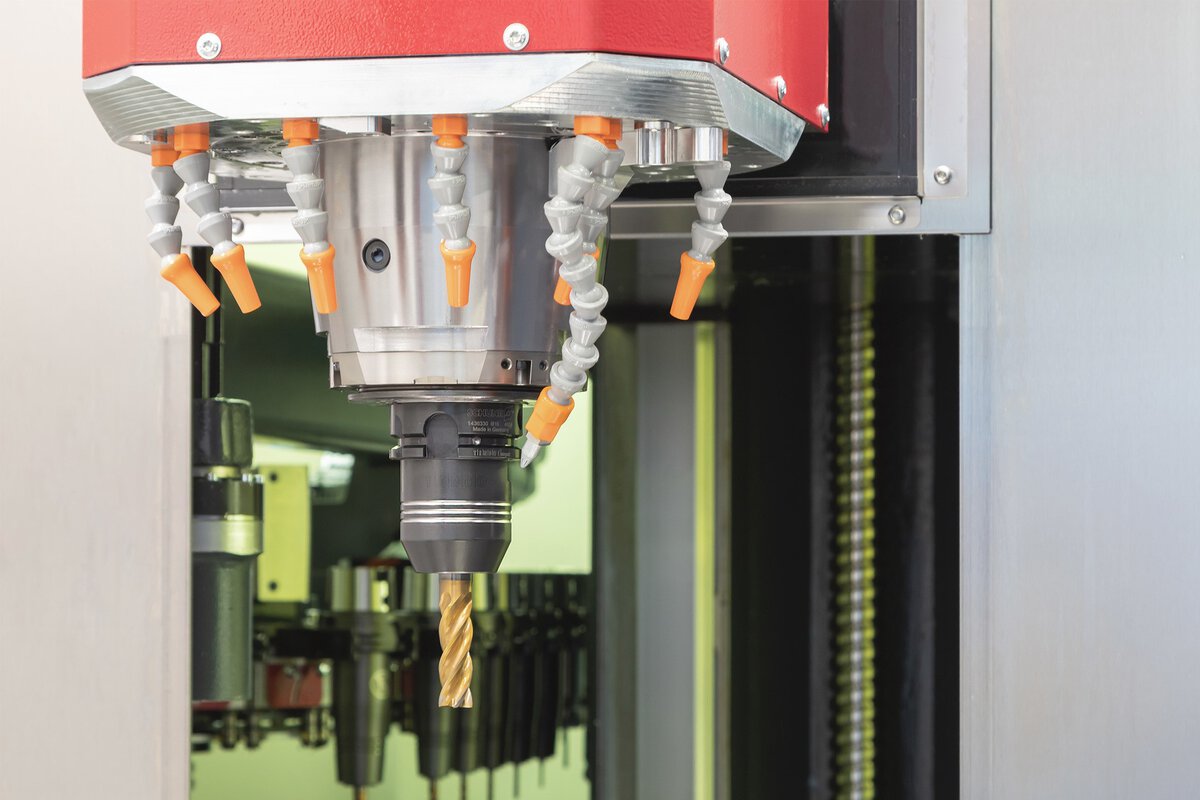

"The tool holders with hydraulic expansion technology were new to us," states Darius Adamski. The project manager initially focussed on classic heat shrink chucks for the new Alzmetall GS 800 purchased in 2019, but was quickly won over by the hydraulic expansion technology of the Tendo series. Tool clamping takes place via a hydraulic system, in which turning a screw compresses the internal pressure medium and elastically deforms the expansion sleeve. The tool shank is thus firmly enclosed. The high voltage and radial rigidity ensure an absolutely safe holder of the tool and precise concentricity. As the market leader in the range of hydraulic expansion technology, Schunk has more than 40 years of experience in this technology. Thanks to an application-specific, differentiated tool holder segmentation, customers can find the right hydraulic chuck variants to suit their application and requirements. Vitronic has the Tendo EC and Tendo Slim 4ax models in use.

The Tendo EC tool holder enables tool changes in seconds thanks to hydraulic expansion technology and ensures precise concentricity. The high clamping force and vibration damping ensure a long tool life and first-class machining results. (Image source still SCHUNK SE & Co. KG)

Users of hydraulic expansion technology have appreciated the economical, efficient and resource-saving machining of parts for decades. These tool holders are finely balanced as standard and suitable for high speeds. The tool shanks can be clamped directly into the chuck - the Tendo series points with its micrometre-precise tool change in a matter of seconds. Users save tooling times and can do without additional peripheral devices. They benefit from a high degree of flexibility, as in addition to direct clamping, it is also possible to use slotted or coolant-tight intermediate bushes for the voltage of different diameters. The permanently precise concentricity and effective vibration damping ensure a long tool life for metalworkers.

Advantage of total tooling: portability and holistic machine equipment

"The fact that we came across the diverse Schunk modular system at the trade fair in 2018 was a stroke of luck for us," confirms Darius Adamski. "Clamping modules and tool holders have proven to be real set-up time killers. On top of that, we have made significant gains in terms of reliability, efficiency and ergonomics." In addition, the functionality of the products is always guaranteed and there have never been any problems or repairs. Darius Adamski and Lukas Seibel would also equip the next machine with the Schunk modular system again. First of all, the HEDELIUS TILTENTA and the Alzmetall GS 800 will be equipped with the KSC3 125-160 clamps for the installation of the SEP five-axis pyramid. The multiple clamping in pyramidal design enables several workpieces to be clamped at the same time, which further reduces tooling times. "If we have any questions, all it takes is a phone call," assures Adamski, summarising: "Complete system, flawless communication, nothing is left to be desired. We value this kind of collaboration - and now we have everything from a single source!"

Source: www.mav.industrie.de

(Image source still SCHUNK SE & Co. KG)

HEDELIUS machining centres &

the customer's automation solutions.

More testimonials.

In prototype construction, Vitronic relies on the modular Schunk clamping technology kit in order to work flexibly, with process reliability and optimised set-up times** in frequently changing clamping situations. Thanks to the Vero-S zero-point clamping system, various clamping devices, lathe chucks and hydraulic tool holders, clamping operations can be transferred quickly, machines utilised efficiently and high-quality machining results achieved. The unit's scalable equipment significantly increases productivity, ergonomics and reliability.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.