Extremely compact 5-axis high-performance machining centres with rotating/swivelling table mounted on both sides for high-precision cutting performance.

CNC machining centres. Made in Germany.

Thousands of users in Europe put their trust in the precision, stability and reliability of HEDELIUS CNC machining centres.

HEDELIUS CNC machining centres are recognised throughout Europe for their precision, stability and reliability. Thanks to the extensive range of accessories, our machining centres can be adjusted to almost any machining task.

Extremely compact 5-axis high-performance machining centres with rotating/swivelling table mounted on both sides for high-precision cutting performance.

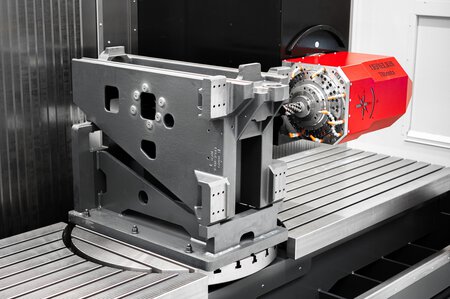

Versatile machining centres with infinitely variable swivelling main spindle and integrated NC rotary table.

Discover the FORTE series - a new class of vertical 3-axis machining centres that offer maximum precision and performance in the smallest of spaces with state-of-the-art Operator's platform design.

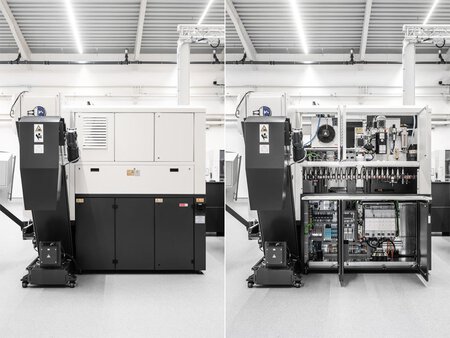

We offer our customers the choice between our in-house HEDELIUS automation solutions and a wide pallet of third-party automation solutions from our renowned partners.

Available Machining centres!

Individually customisable for your requirements.

Stay informed at all times! In our news section, you can find out all about the latest developments, new products and exciting success stories from our customers in a wide range of industries. We also keep you up to date on our trade fair appearances and our own events such as workshops and training courses. Here you will also find the latest downloads of various information material such as our customer magazine HEDline. Check back regularly and don't miss any important updates!

(PDF | EN) Automate your HEDELIUS machining centre with the innovative RoboJob systems and increase your productivity around the clock. Whether small series, medium quantities or unmanned night production: with the Mill-Assist and Tower systems, you can work more economically, reduce downtimes and ensure the long-term competitiveness of your production. Download the free "RoboJob automation for HEDELIUS" folder now and find out how you can upgrade your machining centre to a smart automation solution in just a few steps.

With around 60 employees at its Dillenburg site in Hesse, SIBA Metallverarbeitungs GmbH has been a reliable partner for a wide range of industries for over 60 years. A company that is so comprehensively installed must be able to act highly flexibly in production. This is why SIBA has relied on HEDELIUS machining centres for many years. The company currently relies on two automated systems that ensure maximum precision, unmanned running times and short reaction times: the ACURA 65 EL with PROMOT automation and the ACURA 65 MARATHON with MARATHON SR422 pallet magazine.

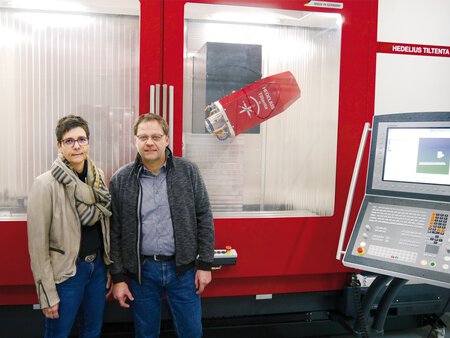

Thanks to the TILTENTA 11- 2600, S&S Schliess- und Sicherungssyteme GmbH in Mühlhausen, Thuringia can now produce even more time-efficiently. Thanks to the generous work area, the integrated swivelling spindle concept and high-performance 5-axis complete processing, one clamping is sufficient for S&S to process complex components completely with the TILTENTA 11- 2600.

Heidkamp Metallbearbeitung in Hüllhorst** relies on maximum flexibility, quality and adherence to deadlines in the production of milled parts. The 5-axis machining centre ACURA 65 EL from HEDELIUS, combined with a large tool store, pallet pool and GRESSEL centric clamps, ensures short tooling times, automated individual and small series production and reliable processes, even with complex components and tight delivery deadlines.

The finest optics in a clean room and modern milling technology under one roof: at VITRONIC in Wiesbaden, high-tech meets craftsmanship. The company develops intelligent image processing systems that are used worldwide in logistics, industry and transport. VITRONIC relies on the TILTENTA 7-2600 NEO from HEDELIUS for maximum precision in production. The machine impresses with its flexible processing of individual and small series, well thought-out design, generous installation space and the possibility of expansion through pallet automation. Find out more about the successful collaboration between VITRONIC and HEDELIUS in the case study.

Highest precision, modern production technologies and a partnership-based cooperation with customers from demanding industries - Fraune Metallbearbeitung GmbH & Co. KG from Delbrück in East Westphalia is committed to this quality promise. In 2022, the family business led by Managing Director Heinrich Fraune took the first step into automated production - with the compact 5-axis machining centre ACURA 65 and the multi-pallet storage system MARATHON SR422 from HEDELIUS.

Our HEDELIUS in-house exhibition on 14 and 15 May 2025 was a complete success - and we owe this above all to you! A big thank you to the numerous visitors, but of course also to our dedicated employees and our strong partners. The personal exchange with our guests, inspiring conversations and new impulses made the two days in our technology centre a real highlight.

Take a look back at this successful event with our event video and the impressions in pictures!

(PDF | EN) The 5-axis machining centres in the ACURA series combine compact design with maximum performance and automation readiness ex factory. Whether single parts or series components up to Ø 900 mm and 1,000 kg are machined with high precision. With innovative technology, generous tool capacity and ergonomic design, ACURA machining centres are perfect for demanding production environments. Download the folder now and discover the full potential of the ACURA!

(PDF | EN) The TILTENTA series, a true universal machining centre. Thanks to its long travel paths and high load capacity, even large and heavy workpieces can be machined. The numerous clamping options are particularly ideal for companies with a large variety of parts. Find out more in the series folder.

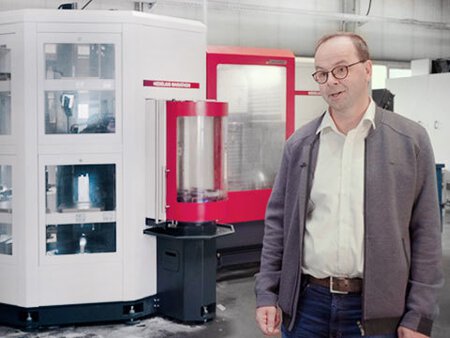

HEDELIUS managing director Dennis Hempelmann presents the outstanding advantages of the FORTE 65 and FORTE 85 machining centres. Thanks to the Operator's platform design, you benefit from maximum dynamics, optimised chip fall and maximum ergonomics. With spacious tool magazines, innovative zero-point clamping technology and intelligent automation solutions, you can sustainably increase your productivity. Experience precision and efficiency at a new level!

How is HEDELIUS meeting the current challenges in European machine tool manufacturing? What role does automation play in this - and what can the industry expect in the future? In this interview, Dennis Hempelmann provides insights into the strategic direction, new machine concepts and the importance of innovation in turbulent times.

Our latest innovation in the video: The TILTENTA 7 NEO, automated with the MARATHON SR415! Experience how our managing director Dennis Hempelmann presents the advantages of this 5-axis universal machining centre with multi-pallet magazine. See for yourself how unutilised potential can be tapped and production processes opened up to a new level of efficiency.

HEDELIUS Maschinenfabrik GmbH in Meppen has once again been awarded the Creditreform CrefoZert creditworthiness certificate. This certificate once again confirms the company's excellent creditworthiness. The strict requirements for the renewal of the CrefoZert continue to be fully met

The demand for efficient automation solutions is constantly growing - especially for the versatile machining centres in the popular TILTENTA series. With decades of experience in the development of compact, ergonomic machining centres and powerful automation solutions, we are pleased to present our latest innovation: the TILTENTA 7-2000 NEO in combination with the MARATHON SR415. A combination that promises maximum productivity with minimum space requirements.

(PDF | DE/EN) All machining centres in the ACURA, TILTENTA and FORTE series are closed in a clear series overview with matching accessory options. The catalogue also contains technical data and spindle diagrams in accordance with these. The catalogue also contains a practical overview of possible automation options for HEDELIUS machining centres.

At Carstengerdes Modellbau und Zerspanung GmbH in Bockhorn near Wilhelmshaven, state-of-the-art technology meets a family working environment characterised by genuine appreciation. With the ultra-modern 5-axis machining centre ACURA 85 and the MARATHON 518 pallet handling system, the company focuses on automation and technical innovation - a major step forward that not only increases efficiency, but also offers young talents enjoyment of their work and long-term prospects.

In manufacturing companies that mainly produce small batch sizes, every spindle minute counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?

Thanks to automation, IWK Verpackungstechnik has been able to significantly increase the production capacity of its HEDELIUS machining centres. By integrating a robot cell, the CNC operators gain valuable time that they can use for the manufacture of single parts. This solution enables IWK to increase its flexibility and further expand production efficiency.

Circelli Engineering Solutions GmbH from Dulliken is one of the start-ups in the Swiss manufacturing scene. Originating as a small design office, the young company has developed into a system provider thanks to its passion and investment in innovative CNC technologies. The founding brothers and owners Paolo Circelli and Marco Circelli explain the role played by the latest FORTE 65 and ACURA 65 machining centres from HEDELIUS.

BL Lasertechnik GmbH turned a disaster into a success story. Despite the devastating fire that destroyed its production halls, the company opted for a quick restart. Thanks to the support of partners such as HEDELIUS, production was resumed and even expanded in a very short space of time.

Experience our 5-axis machining centre ACURA 85 in more detail than ever before: At 600 frames per second, you can experience the interplay of power and precision during machining in our latest slow motion video.

The powerhouse for heavy-duty machining - a TILTENTA 10-3600 from HEDELIUS Maschinenfabrik in Meppen - has been in the production hall just outside the gates of Eindhoven for a year now. The long-established Dutch company De Rooy machines very large, often complex workpieces from a wide variety of materials.

Tooling optimisation and automation mean benefits for entrepreneurs and employees alike. Automation not only reduces tooling times and increases production, but also allows you to utilise previously unproductive times efficiently. We are happy to support you on your open road to more productive production.

"Never change a winning team" - this could be the headline for the collaboration between HEDELIUS Maschinenfabrik and automation specialist BMO at the Dutch manufacturing company Edumar Metaalbewerking. On the way to even more flexible unmanned production, the choice has now been made for the second time in favour of a joint solution from the two manufacturers.

(PDF | EN) We are very pleased to be able to introduce you to our company's sustainability efforts with this brochure. As a family-run, internationally successful manufacturer of CNC machining centres, we have a responsibility - not only towards our customers and partners, but also towards the environment and future generations.

We are pleased to be able to present a new highlight to customers in our technology centre in the future: the beginner-friendly automation RoboJob Mill Assist. The compact workpiece automation with 6-axis robot offers many advantages, especially for beginners. Get an impression of the user-friendly and productive robot automation with our user video.

What could be better for a chipper than perfect chips? In super slow motion at 600 frames per second, chipping on a TILTENTA 11-2600 looks even more impressive. Discover the art of chipping with our latest slow motion video.

We look back on two successful trade fair days with enriching exchanges. It was a special pleasure for us to welcome more than 500 visitors** on 24 and 25 April in Meppen** to this year's in-house exhibition. A big thank you goes to...

Your production process is as individual as your company itself. That's why we offer you a wide range of automation solutions: From precise pallet and workpiece handling to hybrid solutions and advanced linear interlinking systems. We are at your side to successfully close your path to automation.

Despite the current subdued mood in the German machine and plant engineering sector, HEDELIUS is investing in the expansion of its production capacities. In this interview, Managing Director Dennis Hempelmann reveals how HEDELIUS managed to make the past financial year its most successful yet and how he personally assesses the growth prospects for 2024.

We regularly welcome interested customers to our technology centre and offer them the opportunity to see the performance of our CNC solutions for themselves on site and in person. In order to be able to present our latest technologies for more precise and efficient chipping processes, we have recently updated a large part of our exhibition**.

Why do our customers come out on top? CNC machining centres optimised for limited resources such as time, personnel and space guarantee you individual competitive advantages. Everything done right with HEDELIUS.

With the new Infinity series, it is now possible to realise even more unmanned processing time with our machines thanks to the enlarged pallet and workpiece storage space. The system also meets the desire of many users to link several machining centres in a series as a flexible production system.

The trade fair was a complete success! Numerous visitors, exciting discussions and ground-breaking innovations made the EMO 2023 an unforgettable event. We are delighted with the positive response and look forward to shaping the future together.

"In 2012, we were faced with the challenge of having to modernise our entire CNC chipping process," says Tim Sprenger, Production Manager at BAADER, looking back. "We wanted a supplier who was just as interested as we were in a partnership-based collaboration and who would approach the issue with us on an equal footing. We found what we were looking for with HEDELIUS."

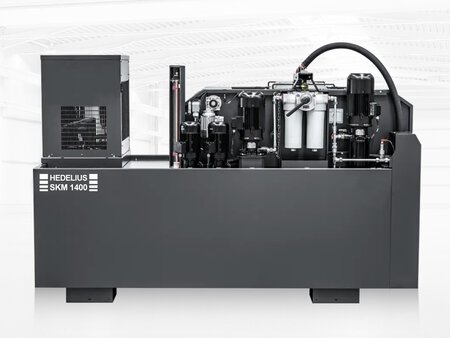

(PDF | EN) The chipping process produces a not inconsiderable volume of chips. By using a chip press directly at the machining centre, you can produce profitable recyclable materials from waste materials that need to be disposed of. This is because the chip press separates the chips from the cooling lubricants and compresses them into clean, manageable briquettes. Find out more about the advantages of a chip press for your production in our new product flyer.

With the introduction of the new Heidenhain TNC7, we are getting ready for the changeover to a new CNC control technology. The training rooms at the HEDELIUS CNC Academy have already been upgraded in accordance with the new technology so that the new functions and possibilities of the TNC7 control can be communicated to the participants in the best possible way.

The Swiss company Meag AG invested in two identical HEDELIUS 5-axis machining centres from the ACURA-85 series with the aim of being able to supply customers even more efficiently and quickly in the future.

The factory halls of Kreiselmeyer Umformtechnik GmbH & Co. KG in Nuremberg are dominated by systems for laser cutting, pressing, turning, edging and welding steel plates. However, with the increasing shift towards the production of complete assemblies, chipping is also becoming increasingly important. With the TILTENTA 7 from HEDELIUS Maschinenfabrik in Meppen, Kreiselmeyer has found the right milling centre.

Get an insight into the HEDELIUS technology centre in Meppen. Thanks to the use of the FPV drone, you get the feeling of being closed in the cockpit of the drone. When flying through the TILTENTA 10 machining centre, the spindle comes very close and you get excellent insights.

We look back on a successful HEDELIUS in-house exhibition on Wednesday, 22 March and Thursday, 23 March 2023. We would like to thank all visitors, co-exhibitors and employees who contributed to the result. Take a look back in the gallery with lots of great pictures and the event movie.

In order to meet the increasing demands of our customers, we have developed our first automation system based on a 6-axis robot, the MARATHON RZ multi-pallet magazine system.

Earthworks for the construction of a new production hall have begun. On a 25,000 square metre site, a state-of-the-art factory for the production, assembly and storage of the TILTENTA series is being built on a total of 10,000 square metres under roof. Completion is planned for spring 2024.

For the seventh year in a row, HEDELIUS Maschinenfabrik GmbH in Meppen has been awarded the Creditreform CrefoZert credit rating certificate. With this certificate, Creditreform Leer Bolte KG once again attests to the company's excellent creditworthiness. The company continues to fulfil the high requirements for an extension of the CrefoZert in full.

See and hear why HEDELIUS has become the preferred supplier of CNC machining centres for thousands of companies in Germany and Europe.

WFT Werkzeug- und Frästechnik GmbH** specialises in the precise production of pre-series and series tools for the plastics processing industry. The company's example impressively demonstrates what can be achieved with the right automation solution - and why employees also benefit from it.

This is why HEDELIUS is now opening a version of the STANDBY MAGAZIN with 264 tool pockets. In total, our customers will then have access to up to 329 tools on a TILTENTA 11 swivelling spindle machining centre and up to 344 tools on an ACURA 85 5-axis machining centre, for example!

MFC - Modell- und Formenbau Chemnitz manufactures aluminium moulds for the plastics processing industry and devices and gauges for vehicle construction on two TILTENTA machines: small, fine workpieces during the day, large workpieces with long running times at night.

With the ACURA 65 MAGNUM and the MARATHON pallet magazine, we have a real ace in our programme for the production of small series. A 90-fold tool magazine, 6 pallets 400 x 400 mm and 250 kg clamping weight ensure your productive edge. Experience it live now at the HEDELIUS demonstration centre.

Anyone visiting WuM Werkzeug- und Maschinenbau GmbH in Mühlhausen, Thuringia, will get an impression of the end products that are manufactured using their tools from the entrance lobby. WuM machines high-precision stamping tools for the automotive industry on a TILTENTA 7, an ACURA 85 and a FORTE 11.

For three days, HEDELIUS and 22 trade exhibitors presented innovative machining solutions on 2200 square metres of exhibition space, including various automation solutions for small and medium-sized metalworking companies with batch sizes from 1 to 500.

Lang Technik GmbH from Holzmaden delivered its ROBOTREX 96 automation solution to Meppen just in time for the in-house exhibition. The automation cell consists of a FANUC 6-axis robot with a payload capacity of 50 kg and two automation trolleys, tooling with a total of 46 vices.

Today, a machining centre must not only work quickly, precisely and reliably, but also look good. HEDELIUS therefore offers a paint finish for the work area doors of all machines according to your colour requirements.

Whether workpiece set-up, tool set-up, programming or maintenance - the focus is always on convenience, safety and productivity in your production. A clear operating and maintenance concept with good accessibility to all working ranges and optimally arranged control elements make daily work easier.

Blowing off the taper by the spindle during tool change has always been standard on HEDELIUS machining centres. HEDELIUS now offers an optional additional blow-off function in the tool magazine, which blows off the taper a second time with a flow-optimised nozzle when it is placed in the tool chain.

HEDELIUS Maschinenfabrik has once again received an order to supply two automated 5-axis machining centres from the ACURA series. The automation is realised by an EROWA ERD 250 linear robot. The entire system is 20 metres long and has 73 pallet stations and 520 tool stations.

With this certificate, Creditreform Leer once again attests to the company's excellent creditworthiness. The company continues to fulfil the high requirements for an extension of the CrefoZert in full. Compared to the previous year, the creditworthiness index was even slightly improved from 108 to 106.

Founded as a supplier to the textile industry, MEM Maschinenbau GmbH from Ahaus is now closed in special machinery, systems and steel construction. With the purchase of an ACURA 65 MARATHON in 2021, the operation led by Managing Director Hans-Jürgen Marx took the plunge into production automation - and it is paying off today.

Constant ambient conditions are required to achieve consistent production results. To achieve maximum accuracy and reproducible results, it is important that the temperature of the workpiece remains constant during processing.

In order to make even better use of the output of our machining centres, the TILTENTA 9, TILTENTA 11 and ACURA 85 series will in future have milling spindles with 37 kW output.

The C axis of our 5-axis machining centres in the ACURA 65 series can now be equipped with a liquid-cooled and backlash-free torque direct drive with 50 rpm. The result: the C axis positions with even greater repeat accuracy, acceleration and speed.

"We at WVG Alu tec from Bad Arolsen have known HEDELIUS for many years and are already something of a family. And where do you trust each other more than within a family?" That's why Gruhs is proud of the "latest achievement", as he puts it: the TILTENTA 7-3200 5-axis machining centre with swivelling spindle and two integrated NC rotary tables.

"After work, the ACURA 65 EL and the BMO Platinum continue to work for us." Jan Inboden and his colleagues are delighted with the reliable technology from HEDELIUS. ERO GmbH from Simmern in Hunsrück is a prime example of a family business that has grown healthily.

The unique HEDELIUS concept with two in-line 5-axis machining centres from the ACURA 50 and ACURA 65 series, which are connected via an automation system, is becoming increasingly popular. Having already sold several systems, we are now pleased to be able to supply the first solution together with EROWA. In this case, the interlinking is carried out by an EROWA Leonardo pallet handling system with 24 pallets of 320 x 320 mm each.

The linking of an ACURA 50 EL and an ACURA 65 EL via the Indumatik 120 pallet handling system is now ready for demonstration. The Indumatik 120 loads the 5-axis CNC machining centres with 400 x 400 and 200 x 200 mm pallets.

The time has finally come: We are proud to present our TILTENTA 11 5-axis swivelling spindle machining centre with a Y travel path of 1,100 mm. We currently offer the TILTENTA 11 with X travel paths of 2,600 and 3,600 mm. Arrange your demonstration appointment in Meppen now!

The trend towards more tools to reduce tooling times has already been taken into account with the introduction of the ACURA 50. The optional expansion of the 55-place tool magazine of the ACURA 50 5-axis machining centre to 80 places offers an additional reduction in set-up costs.

Tscharner Mechanik AG is a small manufacturing company in Prättigau. From the very beginning, founder Bruno Tscharner has focussed on automation. The latest investment is a fully automated production cell with the ACURA 65 5-axis machining centre from HEDELIUS.

The demand for automation solutions continues to grow. Numerous machining centres in the ACURA series have already been equipped with pallet handling systems or robots in recent years. But the demand for automation solutions for our TILTENTA machining centres is also increasing.

Just over 20 years ago, master mechanical engineer Thomas Claaßen took the plunge into self-employment. Today, the Claaßen Group from Scharrel in the Oldenburger Münsterland region employs 250 people in four companies. A clear philosophy and continuous investment, including in automated machining centres from HEDELIUS, have made this development possible.

The SOLLICH KG is the worldwide market leader for chocolate processing machines. The family business from Bad Salzuflen in East Westphalia faced a major challenge when it came to modernising its chipping machinery. Increasingly complex single parts in a wide range of sizes and lengths have to be manufactured flexibly and efficiently. In HEDELIUS Maschinenfabrik, the company found a partner who could make this possible.

With the ACURA 65 and ACURA 85, HEDELIUS has already set standards in the range of 5-axis machining centres with rotating/swivelling table. Now comes the ACURA 50, a new model that impresses with a compactness that is unrivalled with its amazingly large travel paths.

It is hard to deny that automation is finding its way into the factory floor and is an important part of manufacturing concepts. Large companies in particular are often already very advanced in this area. Small and medium-sized companies, the customer base of the northern German family business HEDELIUS, must also follow suit. The mechanical engineering company from Meppen wants to provide support.

As part of the market launch of the compact 5-axis machining centre ACURA 50, HEDELIUS is also launching the ACURA 50 EL, the automatable version of the high-performance machine for small workpieces. The North German family-owned company has focussed on an important detail that can significantly increase production efficiency.

Seeing machines under chip, talking shop, networking - for three days, the machining centres were once again buzzing in the large demonstration centre at HEDELIUS and many of the 300 or so visitors clearly enjoyed feeling the trade fair atmosphere again after the long corona-related break.

If very long tools such as deep hole drills or tools with a large diameter such as disc cutters or spindle tools are required in a HEDELIUS machining centre, the pick-up magazine is the solution.

Fourteen 3- and 5-axis machining centres and four automation solutions are available for individual, interactive live presentations in the HEDELIUS demonstration centre. Follow our experts around and into the machine and ask your questions.

Despite the coronavirus crisis, HEDELIUS Maschinenfabrik considers itself to be well installed, meaning that both product developments and investments in infrastructure are continuing as planned. For example, the company is currently expanding its office capacity at its headquarters in Meppen by 650 square metres.

HEDELIUS Maschinenfabrik GmbH and its local sales partner Promas BV organised a customer day for interested parties and customers from the Netherlands and Belgium on 16 January.

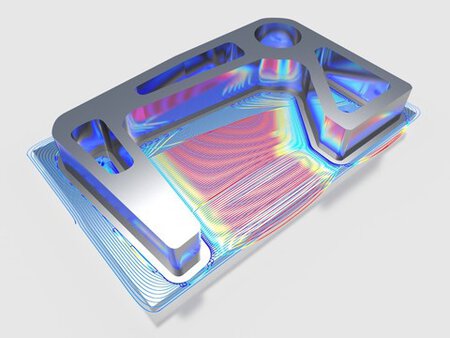

Whirling milling (or trochoidal milling) stands for highly dynamic milling with a high chip volume. Until now, this function was only optimal for slotting. HEIDENHAIN is changing this with a new optional feature for the TNC 640: Optimised Contour Milling (OCM) makes the idea of trochoidal milling available for a much wider range of applications. In addition to roughing open and closed pockets and islands of any shape, OCM also offers cycles for finishing bottoms and side walls.

Forward-looking, responsible and future-orientated action is a top priority at HEDELIUS Maschinenfabrik GmbH from Meppen. Since December 2016, the Emsland-based mechanical engineering company has been awarded the CrefoZert credit rating certificate by Creditreform Leer. In 2019, the family-owned company once again received the award, which is valid for one year.

HEDELIUS Maschinenfabrik GmbH was once again able to record a decent increase in visitors at EMO 2019. Over the six days of the trade fair, 10% more visitors came to the stand than two years ago.

With 510 square metres of stand space, it was the largest stand so far in 2019. It also caught the attention of politicians. On the very first day of the trade fair, Lower Saxony's Finance Minister Reinhold Hilbers made sure to close HEDELIUS.

This year's general meeting of the Verband deutscher Laseranwender -Blechbearbeitung- e.V. (VdLB) took place on 23 February in Lingen (Ems). Over 80 participants travelled to Emsland for the meeting.

The town of Georgsmarienhütte is named after the local steel company, which grew out of the local mining industry. Today, mining vehicles, special machinery and medical technology are manufactured in one of the former industrial halls of Georgsmarienhütte. Here and at another site, Wendt Maschinenbau GmbH und Co. KG manufactures a broad range of parts, machines, steel structures and devices on behalf of customers.

At WERNERT-PUMPEN GmbH, a specialist in the pumping of demanding liquids, the average batch size is between 1 and 100. In mechanical production, a TILTENTA 7-3200 from HEDELIUS with a large contact surface, mobile work area partition, standby magazine and zero-point clamping system creates the best conditions for flexible and productive machining of pump parts of different sizes, numbers and materials.

WKT-Wernemann Kunststofftechnik GmbH** is a second-generation family business that has continued to grow at its founding location in Geeste-Dalum. Since 1994, the company has been manufacturing GRP parts for a wide range of applications and in all shapes, from threaded rods to complete insulating housings. For precise chipping, the company relies on 3-axis and 5-axis machining centres from HEDELIUS.

Development, production and service of special machines and machine components are the mainstays of Zander EMS GmbH. Sophisticated devices and components are developed and manufactured for customers from the automotive industry in particular. Two HEDELIUS machining centres provide the necessary precision and flexibility.

The Trissler & Kielkopf GmbH is located in Reutlingen, at the "gateway to the Swabian Alb". Since the early 1990s, Peter and Christel Dorau have been at the helm of the contract manufacturing company, which will soon be celebrating its 100th anniversary. The Swabian medium-sized company has been relying on HEDELIUS machining centres for 22 years.

The idyllic landscape around Lake Chiemsee invites you to relax and unwind. The region is very popular with holidaymakers. Where others go on holiday, Georg Pfisterer and his 20 employees work on high-precision components for laboratory and medical devices. An ACURA 65 from HEDELIUS has also been in use since 2017.

Sheet metal processing is the core business of the 150-strong medium-sized company mech-tron from Roding. In order to meet the constantly growing customer requirements, one of the leading manufacturers of housings for electronic and embedded equipment has also grown in other technology areas, particularly in milling.

Within just a few years, SD Automotive GmbH has developed into a specialised service provider for the automotive industry. By constantly expanding its machinery, the company has been able to master the high demands placed on milling in particular. The latest technology in the chipping range comes from HEDELIUS in Meppen.

Martin CNC-Präzisionsteile, a contract manufacturing company based in Asslar, Hesse, has opened up its chipping operations to machines from HEDELIUS, thereby significantly expanding its product range. Another benefit: the high level of accuracy thanks to five-sided machining.

It is already the fourth HEDELIUS that Alwin Lamping, owner and managing director of LWM Werkzeug- und Maschinenbau GmbH, has in his machine park. The toolmaker from Vechta did not hesitate for long when making his latest investment. He experienced the ACURA 65 live under chip removal at the last AMB in Stuttgart and was immediately impressed by the extremely compact high-performance machine.

The toolmakers at Gemü rely on the ACURA 65 EL from HEDELIUS for the pre-milling of their tool components. The universal milling machine performs with a robust travelling column construction on a very small footprint. Thanks to the large tool store, automated production also brings great advantages.

Starting out as a small contract manufacturing company, the company from the tranquil community of Weißenstadt with its 3000 inhabitants now employs 25 people and offers national and international customers from a wide range of industries innovative complete solutions in the areas of mechanical engineering, metal and electrical engineering, automation and special machine construction.

The innovative Metallverarbeitung Uwe Ebertz GmbH is based in Sinn-Fleisbach, Hesse. Since its foundation, the family business has undergone a transformation from a sheet metal processor to a comprehensive service provider in metal processing. Modern technologies made in Germany are used, such as the Tiltenta 7-3200 machining centre from HEDELIUS Maschinenfabrik GmbH.

Förster Sondermaschinen GmbH**, based in Lindlar, not far from Cologne, specialises in the manufacture of customer-specific precision components. The batch size of the milled parts produced is usually between 1 and 10: Thanks to a highly flexible, customer-oriented production organisation, the customer can call off the parts as required.

Since its foundation in 1986, D+P, Dosier- und Prüftechnik GmbH has been developing and producing highly complex standard products and customised systems for applying and dispensing liquids, greases and pastes as well as for assembling components and testing functions. The products of the 60-strong company are mainly used in the automotive and electrical industries as well as in mechanical engineering, assembly technology and the air and space industry.

The wind tunnel system at European Transonic Windtunnel GmbH is currently being modernised and its range of capabilities expanded. This also includes the modernisation of the workshop, for which a Tiltenta 6-2300 from HEDELIUS was purchased. This means that full and half models of aeroplanes up to 2.30 m in length can now be machined in a single set-up.

At Edumar Metaalbewerking in Someren, the Netherlands, spindle hours count and production is planned to be highly efficient. Many of the metalworking company's turning and milling machines are therefore equipped with automation solutions. At the beginning of the year, an ACURA 65 EL from HEDELIUS was put into operation with a Titanium 180 from BMO Automation. In combination with the automation system, the 5-axis machining centre is expected to achieve up to 8,000 spindle hours per year.

In the highly competitive sheet metal processing market, BL-Lasertechnik GmbH has successfully made a name for itself. By expanding the value chain to include the milling range, the company is on course for growth and currently employs 90 people.

The success story of Bathon GmbH began over 40 years ago with toolmaking as a sideline. Today, the family business has closed its doors as a versatile service provider in the metalworking industry. Flexible production is an important success factor. A HEDELIUS machining centre is also used for this purpose.

The BAADER Group, which has been in existence for almost a hundred years, has been family-owned since it was founded in 1919 and now employs a good 1100 people worldwide, 500 at its headquarters in Lübeck alone. The centre of gravity at the northern German site is clearly on the production of fish processing machines.

Quality "Made in Germany" - this is what HEDELIUS Maschinenfabrik is recognised for throughout Europe. Founded in 1967, HEDELIUS develops and produces high-performance vertical CNC travelling column machining centres. The machine range includes 3-axis, 4-axis and 5-axis machining centres for the production of single parts as well as small and medium-sized series in machine, vehicle and tool construction. Its customers include numerous well-known machine manufacturers and their suppliers from the agricultural machinery, aviation, vehicle construction, packaging technology and many other industries.

Our daily actions are based on clear principles and values that make us a predictable and reliable partner.

Our experienced service technicians regularly undergo further training and will be on site in no time if something is not working.

The success of our customers spurs us on. Over 3,000 manufacturing companies in Europe rely on machining solutions from HEDELIUS. What makes them so satisfied? Read for yourself.

Extremely compact 5-axis high-performance machining centres with rotating/swivelling table mounted on both sides for high-precision cutting performance.

X: 500 mm | Y: 550/370 mm | Z: 550 mm

Ø 550 mm Sturgeon circuit | max. 300 kg

SK40 / BT40 / HSK A63

The ACURA 50 offers greater precision on a smaller footprint. The constantly guided Y-axis in conjunction with the solidly ribbed feed carriages made of grey cast iron reduce vibrations. The rotating/swivelling table is bearing-mounted on both sides and the Z-axis is specially protected against heat distortion. These and many other details increase the quality of machining, while the dimensions of the 5-axis machining centre are extremely small thanks to the special design.

The machine is loaded through an approx. 600 x 840 mm opening in the right-hand side of the machine. This pneumatically activated stainless steel door of the 5-axis machining centre enables automatic loading of pallets without restricting access to the Machine work area.

The ACURA 50 MARATHON is already prepared for pallet automation at the factory with a permanently installed zero point clamping system and a pneumatically activated loading opening on the right-hand side of the machine. Depending on the variance of the workpiece spectrum, different tool magazines with up to 319 tool positions and main spindles up to 18,000 rpm are available.

X: 700 mm | Y: 650/465 mm | Z: 600 mm

Ø 700 mm Sturgeon circuit | max. 500 kg

SK40 / BT40 / HSK A63

The ACURA 65 high-performance machining centre impresses wherever workpieces need to be machined from several sides with high precision and in the tightest of spaces. Thanks to its low overall depth and low overall height, the 5-axis milling machine can be integrated into almost any workshop. Thanks to the extensive range of accessories, the machine can be adjusted to suit many machining tasks.

The ACURA 65 EL enables manufacturer-independent automation of production using a pallet handling system or a robot from the left-hand side of the machine. This enables unmanned automated production. The door of the 5-axis machining centre remains fully accessible for the manual production of single parts.

The ACURA 65 MARATHON comes with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS MARATHON pallet magazine systems in the series. The ACURA 65 MARATHON remains accessible from the front, even with automation, and the view from the Loading station to the work area is unobstructed. The machining centre has a 65-place tool magazine as standard. As an option, a MAGNUM magazine provides a further 25 tools and a standby magazine provides a further 264 tools.

X: 900 mm | Y: 850/600 mm | Z: 700 mm

Ø 900 mm Sturgeon circuit | max. 1000 kg

SK40 / BT40 / HSK A63

The ACURA 85 offers greater precision on a smaller footprint. The constantly guided Y-axis in conjunction with the solidly ribbed feed carriages made of grey cast iron reduce vibrations. The rotating/swivelling table is bearing-mounted on both sides and the Z-axis is specially protected against heat distortion. These and many other details increase the quality of machining, while the dimensions of the 5-axis machining centre are extremely small thanks to the special design.

The advantage of the ACURA EL concept is that loading from the side allows full access to the work area for set-up and control work, but also for single part production during the day shift, for example. Even crane loading of the machine is possible without restrictions. Another advantage of the 5-axis machining centre (depending on the selected automation) is the visibility of the work area and thus optimised process control during set-up on the automation.

The ACURA 85 MARATHON comes with a built-in zero point clamping system for pallet automation, a side loading opening and an electrical interface for communication with the HEDELIUS MARATHON pallet magazine systems in the series. Even with automation, the ACURA 85 MARATHON remains accessible from the front, with a clear view of the work area from the loading station. The machining centre has an 80-place tool magazine as standard. An additional 264 tools are optionally available by connecting a standby magazine.

Versatile machining centres with infinitely variable swivelling main spindle and integrated NC rotary table.

X: 2000/2600/3600 mm

Y: 700 mm | Z: 695/735 mm

Ø 1050 mm Sturgeon circuit | max. 800 kg

SK40 / BT40 / HSK A63

Compact and automatable - these two terms characterise the TILTENTA 7-2000 NEO. With a 2,000 mm X travel path, the infinitely variable swivelling main spindle and the integrated 5-axis rotary table for workpieces up to 800 kg and 1,050 mm diameter, HEDELIUS offers an uncompromising universal machining centre. Whether aluminium, grey cast iron or tool steel - with this CNC machining centre you can release a wide range of machining tasks in machine, tool and vehicle construction. The many automation solutions are another highlight.

The TILTENTA 7 NEO opens up new areas of application in the machining of single parts and series. Whether end processing of long workpieces or 5-side complete processing with integrated NC rotary table - the TILTENTA 7 crossover concept releases many machining tasks in machine, tool and vehicle construction. The combination of a continuously swivelling main spindle and a long machine table with integrated NC rotary table allows the mixed production of large workpieces and precise 5-axis machining in one machine.

The TILTENTA 7-2600 NEO EL opens up new areas of application for the fully automated machining of single parts and series. Open interfaces and a laterally offset NC rotary table allow an automation system to load the TILTENTA 7 from the left-hand side of the machine. The combination of the infinitely variable swivelling main spindle and the long machine table with integrated NC rotary table allows the mixed production of large workpieces and precise 5-axis machining in one machine.

The equipment with one or two integrated heavy-duty NC rotary tables (optional) and a work area partition enables economical series production of large and heavy workpieces. Changing from one work area to the other in oscillation mode only takes approx. 10 seconds. By simply removing the partition, the entire work area is available for vertical machining of workpieces up to 3600 mm in length.

X: 2600/3600/4600/6200 mm

Y: 900 mm | Z: 900/1005 mm

Ø 1250 mm Sturgeon circuit | max. 1800 kg

SK40 / BT40 / HSK A63

The TILTENTA 9-2600 travelling column machining centre is fully enclosed and also allows unrestricted crane loading. The machine is equipped with a Heidenhain TNC control system with touch display, full keyboard and rapid motion potentiometer as standard. A Sinumerik ONE / 840 D sl is available as an option.

The TILTENTA 9-3600 travelling column machining centre enables speeds of up to 18,000 rpm and spindle outputs of up to 50 kW with a torque of up to 217 Nm. Four axes in the tool guarantee workpiece-independent dynamics - an ideal prerequisite for high rapid motions and feeds of up to 40 m/min.

With travel paths of 4600 x 900 x 900 mm (x/y/z), the TILTENTA 9-4600 offers plenty of space for a wide range of machining tasks. Be it for the vertical machining of workpieces up to 4600 mm in length or for the economical 3- and 5-axis machining of series parts in oscillation mode.

With travel paths of 6200 x 900 x 900 mm (x/y/z), the TILTENTA 9-6200 offers plenty of space for a wide range of machining tasks. Be it for the vertical machining of workpieces up to 6200 mm in length or for the economical 3- and 5-axis machining of series parts in oscillation mode.

X: 2600/3600/4600/6200 mm

Y: 1000 mm | Z: 1000/1165 mm

Ø 1450 mm Sturgeon circuit | max. 2200 kg

SK50 / BT50 / HSK A100

The TILTENTA 10 with travel paths of 2600 x 1000 x 1165 (X/Y/Z) is ideal wherever heavy-duty chipping in machine and tool construction opens up tight spaces. The integrated heavy-duty rotary table allows workpieces weighing up to 2,200 kg to be machined. The standard equipment with the SK50 BIG PLUS duplex contact spindle system (optional: HSK A100) is another highlight of this stable all-rounder.

HEDELIUS has always aspired to build stable machining centres for a wide range of applications. With the TILTENTA 10, we are rounding off the successful TILTENTA series, which has been built hundreds of times. With travel paths of 3600 x 1000 x 1000 (X/Y/Z) and an integrated heavy-duty rotary table up to 1,600 kg / 2,200 kg (optional) table load, this machine will also set standards in machine and tool construction. The TILTENTA 10 is equipped with the SK50 BIG PLUS duplex contact spindle system as standard (optional: HSK A100).

A travelling column machining centre offers clear advantages in single parts and small series production thanks to the ability to produce cubic workpieces in 5 axes, but also to machine long parts vertically or from the end faces. The travel path in the X-axis is therefore an essential criterion when selecting the right machine. The TILTENTA 10-4600 impresses with travel paths of 4600 x 1000 x 1000 (X/Y/Z) and the integrated heavy-duty rotary table up to 1,600 kg / 2,200 kg (optional) table load in machine and tool construction. The TILTENTA 10 is equipped with the SK50 BIG PLUS duplex contact spindle system as standard (optional: HSK A100).

For long and heavy workpieces, a HEDELIUS 5-axis travelling column machining centre from the TILTENTA 10 series plays all the trump cards. Full 5-axis machining up to 2,200 kg, vertical machining up to 6,200 mm, front side processing up to approx. 5,000 mm, oscillating machining, SK50 power - and all this with constant machine dynamics, regardless of the workpiece weight. Thanks to the travelling tool magazine, you as the user benefit from short chip-to-chip times over the entire travel path. Thanks to the numerous accessories such as pick-up magazines for extra-long tools or vertical rotary tables for shaft machining, this machine can be used flexibly and enables you to achieve optimum capacity utilisation and a quick return on investment.

X: 2600/3600/4600/6200 mm

Y: 1100 mm | Z: 900/1005 mm

Ø 1450 mm Sturgeon circuit | max. 1800 kg

SK40 / BT40 / HSK A63

With an impressive 1,100 mm Y travel path, the TILTENTA-11 series from HEDELIUS is entering new dimensions. The TILTENTA 11-2600 opens up new areas of application in the machining of single parts and series in machine, tool and vehicle construction. Whether for machining long workpieces or 5-side complete processing with an integrated NC rotary table - the TILTENTA crossover concept releases many tasks. The combination of a continuously swivelling main spindle and a long machine table with integrated NC rotary table allows the mixed production of large workpieces and precise 5-axis machining in one machine.

With 4 axes in the tool, the TILTENTA 11 impresses with excellent dynamics, regardless of the workpiece weight, creating ideal conditions for high rapid motions of up to 40 metres per minute. Equipped with powerful, liquid-cooled CELOX motor spindles, this 5-axis machining centre impresses with its high cutting output and precision. The large X-axis, Y-axis and Z-axis as well as the rigid machine bed set standards.

Thanks to the travelling tool magazine of the TILTENTA 11, tool changes only take a few seconds despite the 4600 mm travel path. The standard 65-cavity tool magazine already reduces your tooling times as standard. With a work area partition, the machine can also be loaded in oscillation mode during machining. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 5-axis machining centre.

Thanks to the travelling tool magazine of the TILTENTA 11, tool changes only take a few seconds despite the 6200 mm travel path. The standard 65-position tool magazine already reduces your tooling times as standard. With a work area partition, the machine can also be loaded in oscillation mode during machining. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 5-axis machining centre.

Discover the FORTE series - a new class of vertical 3-axis machining centres that offer maximum precision and performance in the smallest of spaces with state-of-the-art Operator's platform design.

X: 1120 mm | Y: 550 mm | Z: 550 mm

SK40 / BT40 / HSK A63

With the optional zero-point clamping systems, the tooling times of the

FORTE 50 Single 1120 can be significantly reduced. They are a useful addition, especially for single parts to medium series production.

The FORTE 50 EL has a pneumatic

actuated loading opening on the right-hand side as standard. This enables automatic loading of pallets or workpieces without

restricting access to the Machine work area.

X: 1320 mm | Y: 650 mm | Z: 600 mm

SK40 / BT40 / HSK A63

When high cutting performance and precision are required in the smallest of spaces, the FORTE 65 Single 1320 3-axis machining centre is the right choice. The modern Operator's platform design impresses with its high dynamics, regardless of the workpiece weight. With travel paths of 1320 x 650 x 600 mm, the travelling column machining centre offers a surprising amount of space with small installation dimensions. Direct position measuring systems on all axes and the latest generation of drive technology ensure long-term precision.

If high cutting performance and precision are required to implement your automation project, the FORTE 65 EL 3-axis machining centre is the right choice. The modern Operator's platform design impresses with its high dynamics, regardless of the workpiece weight. The machine has a pneumatically activated loading opening on the left-hand side as standard. This enables automatic loading of pallets or workpieces without restricting access to the Machine work area. The large selection of interfaces for different automation manufacturers such as EROWA, INDUMATIK or BMO opens up countless automation options.

X: 1620 mm | Y: 850 mm | Z: 700 mm

SK40 / BT40 / HSK A63

The large machine window and the fixed machine table ensure that everything is open to the operator so that the work area can be optimally utilised. Direct access to the workpiece is further supported by the ergonomic working height of the machine table. Vertical stainless steel covers ensure optimised chip fall - even when machining aluminium in bulk. This means that little time is spent on cleaning when working with the precise 3-axis milling machine.

X: 2000/2600/3600 mm

Y: 700 mm | Z: 800 mm

SK40 / BT40 / HSK A63

Where conventional CNC machining centres with a moving table reach their technical limits in terms of travel paths, dynamics, table load and chip removal, the FORTE 7 series offers a solution. The Operator's platform design impresses with its high table load, consistent dynamics (regardless of workpiece weight) and optimised chip fall. The closed full cabin and integrated exhaust system ensure a clean working environment. The sliding control panel and the large viewing windows make set-up and process control easier for the operator.

The FORTE 7-2600 NEO 3-axis machining centre opens up new areas of application for the machining of single parts and series. By inserting a work area partition, the long basic work area can be divided in two for loading and unloading during machining. This enables productive oscillating machining.

The travelling column concept of the 3-axis machining centre with bottom-mounted cast iron bridge offers ideal conditions for high rapid motions and feeds of up to 40 m/min. Liquid-cooled motor spindles with speeds of up to 18,000 rpm and outputs of up to 35 kW ensure high cutting performance with uncompromising precision.

X: 2600/3600/4600/6200 mm

Y: 900 mm | Z: 1005 mm

SK40 / BT40 / HSK A63

The FORTE 9 3-axis machining centre extends the successful FORTE series from HEDELIUS upwards. Designed for chipping with modern high-performance tools, the FORTE 9-2600 has a 60-fold tool magazine and large travel paths of 2600 x 900 x 1005 mm. The sophisticated travelling column concept impresses with its impressive output, precision and dynamics when machining large parts.

The travelling 60-position tool magazine guarantees tool changes in a matter of seconds. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 3-axis machining centre.

The travelling column concept of the 3-axis machining centre demonstrates its superiority particularly with large and heavy workpieces, as the dynamics of the machine are independent of the workpiece weight. The torsion-resistant travelling column made of grey cast iron impresses with its high stability and vibration damping.

The FORTE 9-6200 sets new standards in the processing of large workpieces. With a travel path of 6,200 mm, outstanding dynamics and a stable travelling column made of grey cast iron, it guarantees maximum precision and vibration damping - even for heavy-duty tasks. Ideal for demanding production processes.

X: 2600/3600/4600/6200 mm

Y: 1000 mm | Z: 1165 mm

SK50 / BT50 / HSK A100

When high output is required in a small space, the FORTE 10-2600 3-axis vertical machining centre is the first choice. Thanks to the high-quality standard equipment with direct measuring systems, stainless steel slats, smooth-running work area doors and the powerful milling spindle with SK50, BT50 or HSK A100 tool holder, you can produce precisely and economically.

The FORTE 10-3600 is an impressive 3-axis vertical machining centre with extra-large travel paths, a particularly powerful milling spindle with SK50, BT50 or HSK A100 tool holder, a 40-position tool magazine as standard and an extensive range of accessories. This machining centre will become the productive centre of your production.

Thanks to the extensive range of accessories such as rotary tables, vacuum pumps, pick-up magazines for extra-long tools or a hydraulic clamping system for the automatic activation of devices, we can customise the FORTE 10 series to meet your individual requirements. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of these high-performance vertical machining centres.

With a 6200 mm X travel path, this machining centre rounds off the successful FORTE 10 series. Generously dimensioned recirculating roller guides, polished ball roller spindles and direct Heidenhain measuring systems in all axes guarantee outstanding rigidity combined with maximum accuracy and dynamics. The travelling column and machine table are made of heavy grey cast iron. This is an essential criterion for an SK50/HSK 100 machine to ensure high surface quality and low tool wear even in difficult-to-machine materials. Thanks to the extensive range of accessories such as rotary tables, vacuum pumps, pick-up magazines for extra-long tools or a hydraulic clamping system for the automatic activation of devices, we can customise the FORTE 10 series to meet your individual requirements.

X: 2600/3600/4600/6200 mm

Y: 1100 mm | Z: 1005 mm

SK40 / BT40 / HSK A63

With the FORTE 11, HEDELIUS Maschinenfabrik is setting another benchmark in 3-axis machining. With a Y travel path of 1100 mm, the machining centre expands the popular FORTE series. With 65 tools as standard and travel paths of 2600 x 1100 x 1005 mm (x/y/z), this machine is particularly suitable for chipping solid parts or machining several small parts.

The FORTE 11-3600 3-axis machining centre impresses with its wide range of applications in various industries. Whether machine or tool construction, vehicle construction or aerospace - the FORTE series from HEDELIUS sets standards wherever long workpieces are machined economically with high precision. With the powerful milling spindles, a 65-position tool magazine as standard and the extensive range of accessories, this machining centre will become the productive centre of your production.

Despite a travel path of 4600 mm, tool changes on the FORTE 11-4600 take just a few seconds. The large, travelling 65-cavity tool magazine also reduces your tooling times as standard. Perfectly designed work areas with vertical slat covers and good accessibility to the work area round off the overall concept of this 3-axis machining centre.

Maximum precision with a large travel path: The FORTE 11-6200 impresses with an impressive travel path of 6200 mm and a quick tool change in just a few seconds. The travelling 65-position tool magazine significantly reduces tooling times. Perfectly designed work areas with vertical slat covers and excellent accessibility offer ideal working conditions.

for CNC machining centres

Increase the accuracy of your production with the help of advanced touch probes and lasers.

By using a partition in your machining centre, two closed, independent work areas for chipping in oscillation mode can be created from one work area.

The machine table is equipped with a standardised interface that reduces the centring and alignment of devices to just a few seconds.

To extend the range of applications of your TILTENTA from 5-sided machining to 5-axis simultaneous processing.

Attachment rotary tables to extend the axes and increase the performance spectrum of your CNC machining centre.

Enable multi-sided machining with multiple clamping and thus rationalise series production.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres.

Ensuring a technological edge: High-output and high-torque CELOX integral motor spindles with hybrid bearing technology.

Increased operating comfort and relief for machine operators.

HEDELIUS offers a paint finish for the work area doors of all machines according to your colour requirements.

A chip press separates chips from cooling lubricants and compresses them into clean, manageable briquettes.

Machining centres direct from the manufacturer. Very short delivery time!

Find the right CNC machining centre for you.

Automation solutions and open interfaces for third-party providers to increase efficiency.

+ Automation of machining centres with rotating/swivelling table

+ Lateral loading by the automation system

+ Work area remains fully intact

+ Solutions with low space requirements

+ Automation of long-bed milling machines with swivelling spindle

+ Front loading through the automation system

+ Work area remains intact

+ Solution for 5-axis and long part machining

+ Automation of 3-axis milling machines

+ Lateral loading through the automation system

+ Work area remains fully intact

+ Solutions with low space requirements

Automation solutions for single parts as repeat parts or small to medium series with pallets.

With six pallets measuring up to 400 x 500 mm and a maximum transfer weight of 370 kg, the super-compact MARATHON PL406 pallet magazine is a space-saving productivity booster for the ACURA series. For easy operating, the automation system has buttons for rotating the pallet carrier and for acknowledging raw parts. The job list is created on the HEIDENHAIN control system in the Batch Process Manager.

With up to 34 pallets, the MARATHON RZ430 multi-pallet magazine is ideal when single parts need to be produced as repeat parts or small to medium series. Pallet handling is performed by a 6-axis YASKAWA robot with a load capacity of 88 or optionally 110 kg. Two pull-out storage/retrieval stations guarantee maximum productivity even with short program runtimes. The highlight is the MultibatchOS pallet and order management system with an 18.5" widescreen touch display. The automation system is perfectly open to the ACURA 50 and ACURA 65 5-axis machining centres.

With 22 pallets, the MARATHON SR422 multi-pallet magazine is ideal for producing single parts as repeat parts or small to medium series. One highlight is the consistent operating concept of the ACURA 65 MARATHON with Heidenhain TNC - at the machine, at the tool terminal of the standby magazine and at the pallet magazine terminal. The automation system is perfectly open to the ACURA 65 5-axis machining centre.

With 18 pallets of 500 x 500 mm each, 700 mm interference circle and 470 kg transfer weight, the MARATHON SR518 multi-pallet magazine is designed for handling large, heavy single parts as repeat parts or small to medium series. The powerful ACURA 85 5-axis machining centre, the optional 50 kW spindle and a 344-position STANDBY tool magazine form a perfectly coordinated team for maximum productivity. The operator can keep an eye on the machine's work area at all times from the 360° rotating storage/retrieval station. The work area remains fully accessible from the front for process control and loading new workpieces.

The TILTENTA series is known for its flexibility,

reliability and cutting performance. The new

TILTENTA 7-2000 NEO offers generous travel paths

of 2000 mm in the X-axis, 700 mm in the Y-axis

and 735 mm in the Z-axis. The pallet magazine

has 15 pallet locations for components with a diameter of up to

700 mm and a clamping height of 500 mm.

The storage/retrieval station can also be rotated so that clamping towers or clamping pyramids, for example,

can be ergonomically

tooled. For full flexibility, the MARATHON SR415 loads the TILTENTA 7 fully automatically from

the left-hand side of the machine.

The EROWA ERC 80 loads the ACURA 50 EL 5-axis machining centre with 320 x 320 mm pallets. The multi-pallet magazine has a capacity of 10 pallets of 320 x 320 mm each (optionally 16 pallets), with a transfer weight of 80 kg. Alternatively, the pallet magazine can also handle smaller pallets, e.g. up to 24 pallets with a diameter of 210 mm. The special feature of this concept is the small space requirements of approx. 4480 mm.

Just as much as necessary. That is the concept behind the EROWA Robot Dynamic 150L. You only procure as much automation as is currently required. If the production capacity requirements change, the Robot Dynamic system can be expanded modularly at any time. The slim linear rail is extended to the required length using individual segments. The magazine levels are configured specifically for the task at hand.

The EROWA Leonardo is a pallet handling device with multi-level magazines. The transfer weight is 80 kg (optional features 120 kg). The X-axis has a long travel path and therefore also reaches into large machines. The few necessary commands are entered via a touchscreen pad. The integrated control has a high degree of autonomy. Pallets are automatically placed in an available position.

With the INDUMATIK Light 30, the machining centre can be quickly and easily converted from manual to automated operation. With 50 pallet locations for different workpieces, the ACURA can also be operated in unmanned shifts. The integrated storage and retrieval station allows the operator to remove finished parts at any time and load them with new parts at the same time. The optional InduCell control software checks the NC programs and the tool table to ensure continuous chipping.

With the INDUMATIK Light 60, the machining centre can be quickly and easily converted from manual to automated operation. With 24 pallet locations for different workpieces, for example, the HEDELIUS ACURA can also be easily operated in unmanned shifts. The integrated ergonomic storage and retrieval station allows the operator to remove finished parts at any time and load them with new parts at the same time. The optional InduCell control software checks the NC programs and the tool table to ensure continuous chipping.

With the INDUMATIK Light 120, the machining centre can be quickly and easily converted from manual to automated operation. With 30 pallet locations for different workpieces, for example, the HEDELIUS ACURA can also be operated in unmanned shifts. The integrated storage and retrieval station allows the operator to remove finished parts at any time and load them with new parts at the same time. The optional InduCell control software checks the NC programs and the tool table to ensure continuous chipping.

Designed as a flexible manufacturing system (FMS for short), the Indumatik 150 allows both the automation of a machining centre and the automation of a multi-machine system. The Indumatik 150 has a flexibly expandable pallet storage system and a rotating handling device that can be moved on a floor rail. Clamping of the workpieces

Robot cells manage workpieces from grid drawers fully automatically for small and medium batch production.

The Iridium Hybrid from BMO combines two worlds in the automation of a CNC machining centre: flexible automation of small series using devices with pallets and series production of e.g. sawing sections by inserting workpieces directly into the machine. The Iridium impresses on the one hand with its compact dimensions of just 1,500 mm in width and on the other with a capacity of 20 pallets measuring 200 x 200 mm and a storage drawer for 50 workpieces measuring up to 100 x 100 mm.

The Platinum robot cell is suitable for loading workpieces onto up to two CNC machines. The workpieces are removed from grid drawers by a 6-axis robot and inserted into the machine. In order to be able to react very flexibly to small batch sizes and increase the unmanned running time of the system, the Platinum automation solution also has eight pallet locations for holding the clamping devices. This means that the robot automation first automatically inserts the required clamping device into the machine and then tools the device from the storage drawer with the raw parts.

The Titanium model has up to 100 pallet magazine locations and two pallet loading stations to process workpieces or pallets in combination. Robots weighing 180 kg or 225 kg are available to ensure that even heavy workpieces can be processed on pallets. To remove the high chip volume, the machines in the ACURA series can be equipped with special accessories such as work area rinsing and alternative chip conveyors.

While the number of workpieces that can be processed in the robot cells of the Platinum and Titanium series is limited by the number of drawers, the robot cells of the Infinity series can accommodate an almost unlimited number of workpieces and pallets. This is made possible by flexibly divisible shelves and integrated height control for optimum utilisation of the shelf capacity. The workpieces are stored on grid trays. In order to be able to react very flexibly to small batch sizes, heavy parts or complex clamping situations, the Infinity solution has pallet locations for holding a wide variety of clamping devices. As true multi-batch automation, the robot first automatically inserts the required clamping device into the machine and then tools the device from the trays with the raw parts.

This beginner-friendly automation system has been specially developed for tooling and unloading small series and/or small workpieces. The automation has a 6-axis robot that takes the workpieces from a fixed table and places them in the 5-axis machining centre of the ACURA series. Depending on the space available, the system can load the machine from the front or from the side.

If high flexibility and autonomy are required, the ROBOJOB Tower is worth a look. A vertical lift system stores not only workpieces but also clamping devices and pallets on up to 28 levels. As an option, the system can be equipped with additional pallet racks and a storage/retrieval station for very heavy or very large workpieces.

If high flexibility and autonomy are required, the ROBOJOB Tower is worth a look. A vertical lift system stores not only workpieces but also clamping devices and pallets on up to 28 levels. As an option, the system can be equipped with additional pallet racks and a storage/retrieval station for very heavy or very large workpieces.

The RoboTrex automation cell consists of a Fanuc 6-axis robot with payloads of up to 50 kg. The workpieces are stored using vices on mobile automation trolleys. The patented, upright mounting of the vices ensures optimised utilisation of the footprint. The automation trolleys allow workpieces to be clamped and unclamped even at a great distance from the machine. An automation trolley can be removed or exchanged during machine operation. The RoboTrex 96 system also has a gripper changer to enable different sizes of shear frames to be processed. In conjunction with the automatic recognition of the automation trolleys, the system offers a high degree of flexibility and covers a wide variety of parts.

Automation solutions that combine workpiece and pallet handling in one system

Mirror-image version of the ACURA 50 and ACURA 65 enables interlinking with pallet or workpiece systems.

Separate tool stores for up to 264 additional tools clean, maintain and reduce changeover times enormously.

Preconfigured standard interfaces, e.g. for EROWA, INDUNORM, ROBOJOB, BMO or LANG, are available for the electrical connection to an automation system.

With over 3,000 HEDELIUS machining centres installed today, we ensure precise and powerful chipping in a wide range of industries.

Various design highlights ensure that our customers can achieve maximum precision and efficiency in every production step in the long term.

By using set-up time-optimised technology, such as fast tool provision and innovative clamping devices, companies can maximise their spindle running time in the long term.

Increase the accuracy of your production with the help of highly developed touch probes and lasers.

By using a partition in your machining centre, two closed, independent work areas for chipping in oscillation mode can be created from one work area.

The machine table is equipped with a standardised interface that reduces the centring and alignment of devices to just a few seconds.

To extend the range of applications of your TILTENTA from 5-sided machining to 5-axis simultaneous processing.

Attachment rotary tables to extend the axes and increase the performance spectrum of your CNC machining centre.

Enable multi-sided machining with multiple clamping and thus rationalise series production.

The factors that have a significant influence on the accuracy of our precision machines.

Optimise your HEDELIUS machining centre with a wide range of optional features that are precisely tailored to your specific requirements and production tasks.

State-of-the-art control technology from SIEMENS or HEIDENHAIN guarantees maximum operating convenience and unrestricted functionality.

The TNC7 combines high-quality hardware components with an advanced, customisable user interface and a generous package of functions.

With SINUMERIK ONE, you can set new standards in your production thanks to digital twins, extended diagnostic functions and a high degree of flexibility.

The implementation of high-pressure coolant systems is a decisive step towards significantly increasing the performance of your CNC machining centre.

Increase the efficiency of your production with our advanced cleaning technology for HEDELIUS machining centres.

Technologischen Vorsprung sichern: Leistungs- und drehmomentstarke CELOX-Integral Motorspindeln mit Hybrid-Lagertechnik.

Increased operating comfort and relief for machine operators.

HEDELIUS offers a paint finish for the work area doors of all machines according to your colour requirements.

A chip press separates chips from cooling lubricants and compresses them into clean, manageable briquettes.

The advancing digitalisation in the manufacturing industry is opening up completely new opportunities to make chipping processes more transparent, faster and more efficient. We at HEDELIUS also take the increasing importance of intelligent interlinking of production, quality and machine data seriously. The aim is to digitally support the entire value-added process from order planning to the finished machined component.

+ Personalised. On site nationwide.

+ Intelligent deployment planning.

+ Excellent spare parts availability.

Fast, professional solution when servicing is required.

+ Service enquiries

+ Maintenance enquiries

+ Spare parts enquiries

Current information and news about HEDELIUS Maschinenfabrik. A brief insight into the product variety of machining centres, automations and events.

We provide a wide range of free information material in our download area.

All upcoming dates for workshops, trade fair appearances and other events at a glance.

Over 3000 well-known customers from all over Europe trust in the quality and reliability of HEDELIUS machines.

Interesting facts about the company, news, product information, user reports

For 55 years, HEDELIUS has had only one goal: to increase economic efficiency in single parts and small series production in machine, tool and vehicle construction.

Take the opportunity to experience our machining centres and automation solutions live and see their performance and safety for yourself.

Thousands of companies in Europe, including hidden champions, rely on our solutions. From SMEs to global corporations, we accompany you on the path to sustainable success.

Comprehensive and practical training for CNC programmers and operators from 3-axis to 5-axis machining.

Experience the latest developments in machining technology - either conveniently online or directly with us in Meppen.

HEDELIUS brand machining centres are used in a wide range of industries.

Conserving resources, energy efficiency and safeguarding the future: our efforts to make a positive contribution to shaping a sustainable future.

As a supplier, do you share our values of quality and reliability? Then please feel free to open a dialogue with us.

Over the years, we have built up a strong network of 17 trading partners throughout Europe.